Method and device for spot-firing seed metering

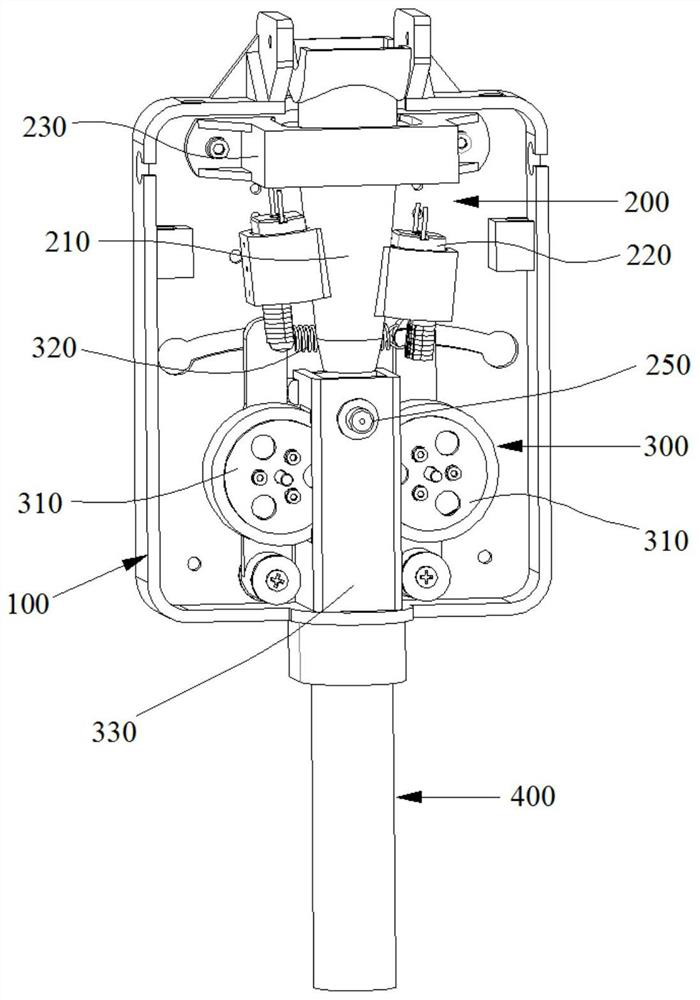

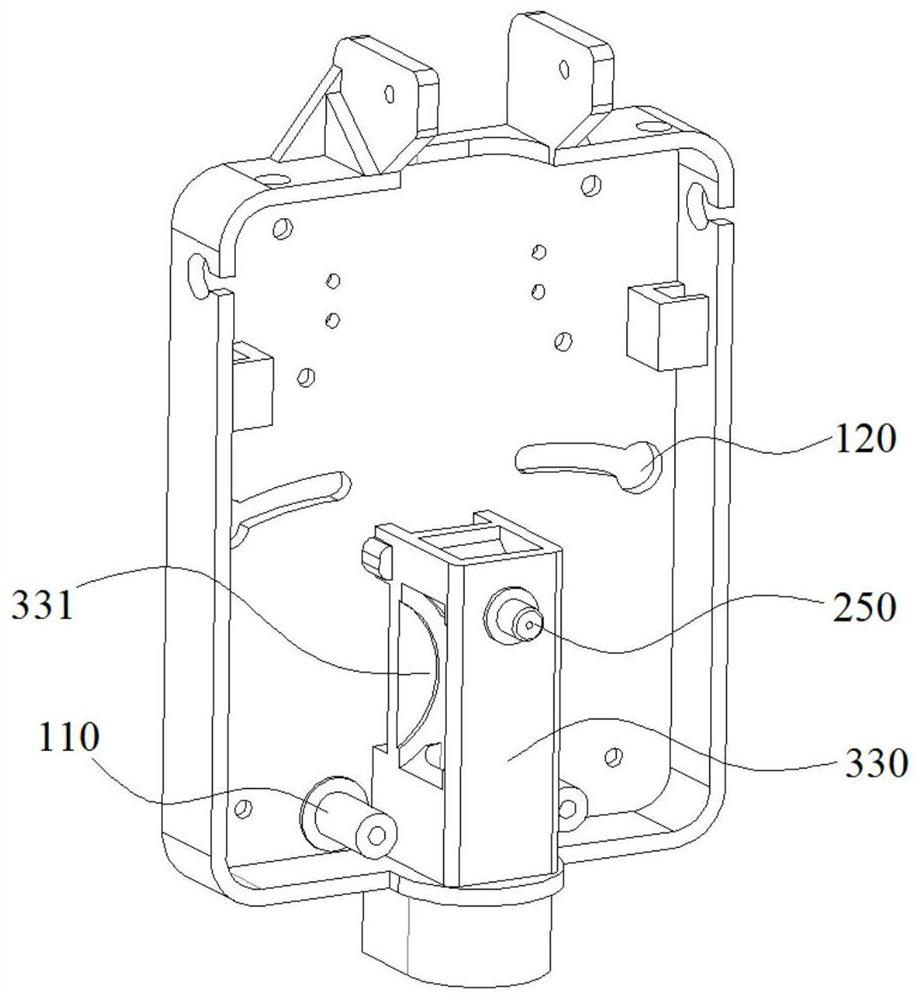

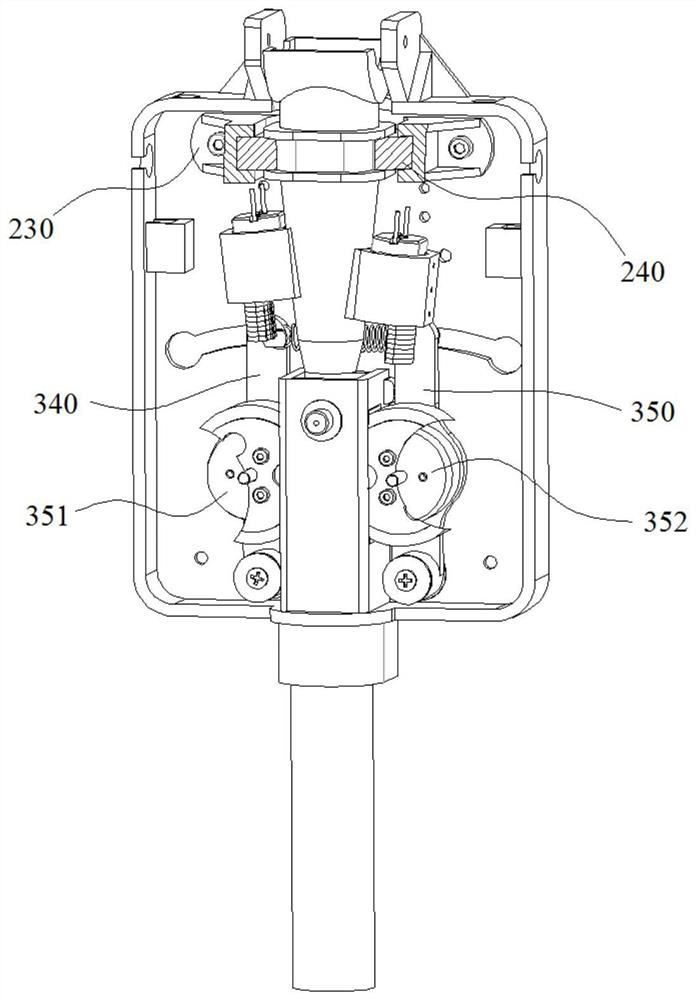

A seed metering device and seed technology, which is applied to launch devices, planter parts, transportation and packaging, etc., can solve the problems of uncontrollable seed placement, high manufacturing precision, and high seed particle overlap rate, so as to improve seeding efficiency and seeding. accuracy, improve continuity and uniformity, ensure real-time and high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] In this embodiment, a shot-type seed metering method, such as Figure 8 shown, including the following steps:

[0090] S1 calibration parameters: calibrate and store the control parameters of the burst type seed metering;

[0091] S2 Vibration queuing for seeding: filling the cone with seeds through the seed feeding port to control the vibration of the cone, the seeds flow under the action of vibration, and are discharged from the seeding head;

[0092] S3 friction acceleration: make the falling seeds generate the same friction force as the preset injection direction on both sides, so that the seeds can be discharged at high speed with the acceleration corresponding to the friction force;

[0093] S4 adjust the direction: guide the seeds discharged at high speed, so that the seeds can be accurately shot to the target position.

[0094] In step S1, according to the size and fluidity of the seed to be filled, the appropriate seed filling flow rate, the aperture of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com