Efficient packaging device for photovoltaic solar coated glass

A technology of photovoltaic solar energy and coated glass, applied in packaging and other directions, can solve the problems of low packaging efficiency and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

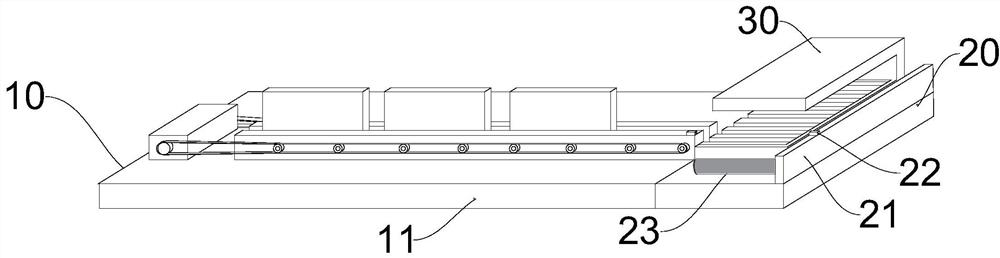

[0033] Such as Figure 1-5 As shown, it is a structural schematic diagram of a photovoltaic solar energy coated glass high-efficiency packaging device in a preferred embodiment of the present invention. The packaging table 20 in this embodiment includes a baffle 21, and the baffle 21 is fixedly connected to the On the upper top surface of the right side of the packing table 20, the upper end surface of the baffle plate 21 is provided with a receiver 22, and the surface of the packing table 20 is provided with a roller 23, and the roller 23 is controlled by the receiver 22, so The conveying assembly 10 is connected to the left side of the packing table 20 described above. When the photovoltaic glass is transported to the left side of the packing table 20 through the conveying assembly 10, the receiver 22 receives the information and commands the roller 23 to rotate;

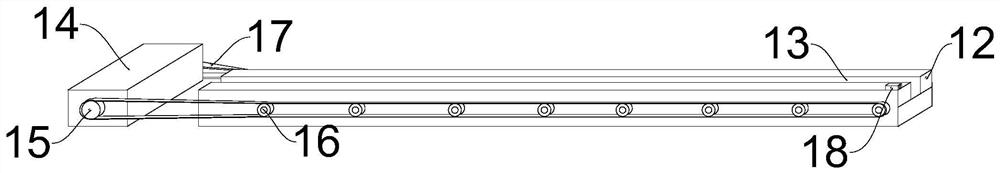

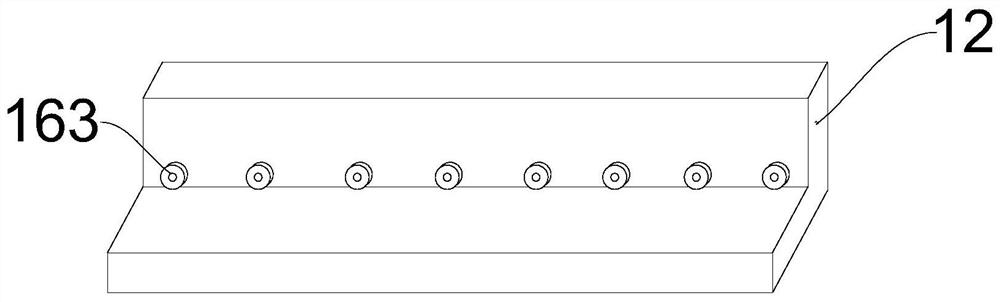

[0034] The conveying assembly 10 includes a base plate 11, the upper surface of the base plate 11 is connected ...

Embodiment 2

[0037] Such as Figure 6-8 As shown, it is a structural schematic diagram of a high-efficiency packaging device for photovoltaic solar coated glass according to another preferred embodiment of the present invention. The packing box 30 includes a box body 31, and fixing plates are arranged at both ends of the inside of the box body 31 32, the inner lower surface of the box body 31 is provided with grooves 33, the grooves 33 are symmetrically distributed with respect to the middle parallel line of the box body 31, and the left side of the box body 31 close to the bottom is connected to the backing plate 34 , a cover plate 35 is provided above the backing plate 34, a bolt 37 is provided at the end of the left side of the cover plate 35 near the top, and a fixing port 36 is installed on the side of the box body 31 near the top;

[0038] On the basis of Embodiment 1, when the conveying assembly 10 transports the glass to the side close to the packing platform 20, the packing box 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com