BIM assisted vertical mill construction method

A vertical mill and bolt technology, applied in infrastructure engineering, special data processing applications, geometric CAD, etc., can solve problems such as affecting construction period, high requirements, and error-prone, improving accuracy and programming, and reducing construction costs. , the effect of reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

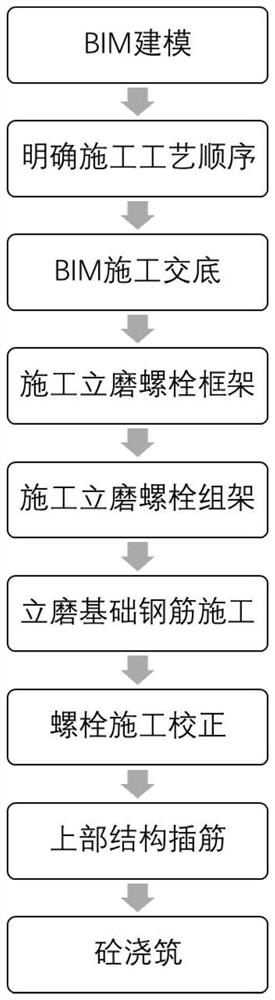

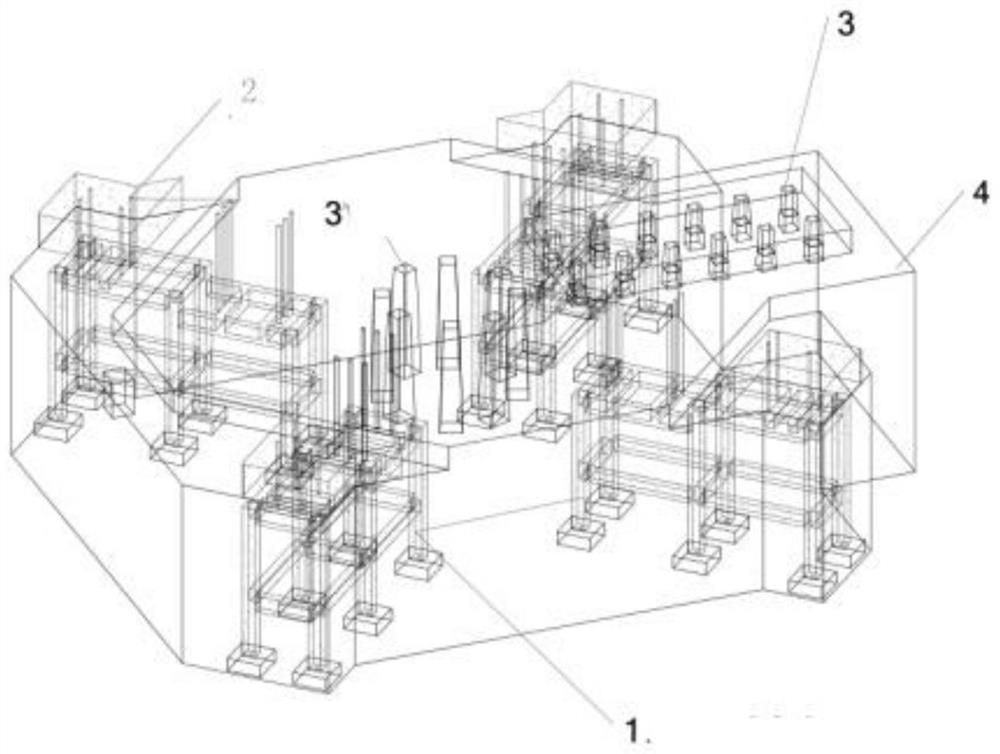

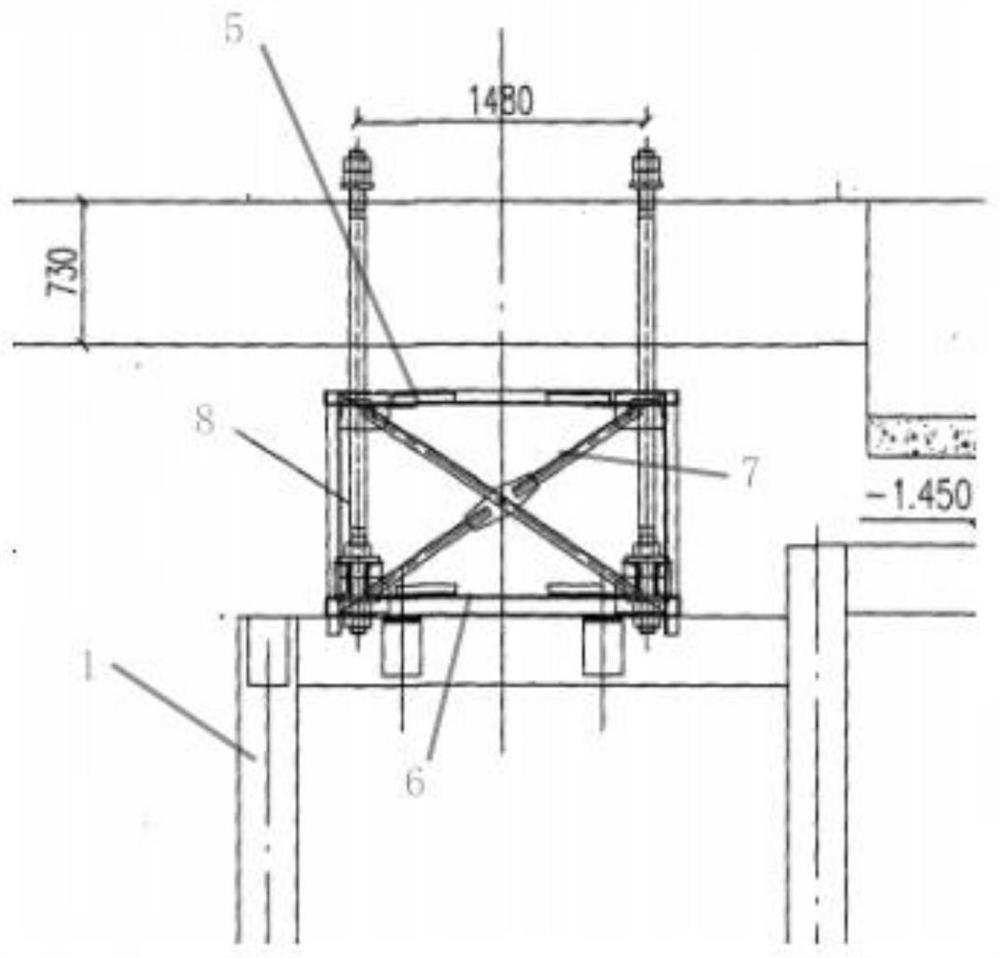

[0025] Such as Figure 1 to Figure 4 As shown, a method for BIM-assisted vertical mill construction includes the following steps:

[0026] Step 1: Model the vertical mill as a whole according to the design size of the vertical mill drawing, clarify the elevation of the concrete surface, mark the bolt fixing bracket and bolts of the vertical mill in the BIM model, and eliminate the ambiguity in the design drawing through BIM modeling , what you see is what you get;

[0027] Step 2: Define the process sequence through the BIM model;

[0028] Step 3: Make disclosure to the construction personnel through BIM;

[0029] Step 4: Vertical mill foundation construction:

[0030] The construction of the vertical mill bolt frame 1 and the bottom plate reinforcement, the construction bolt assembly and bolt 2, the construction skeleton reinforcement, the top reinforcement of the construction foundation, the correction of the bolt 2, the insertion of the superstructure reinforcement, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com