An anti-seepage device and anti-seepage method for water supply and drainage pipes for construction engineering

A technology for anti-seepage devices and water supply and drainage pipes, which is applied in the direction of water supply devices, water supply main pipelines, water supply pipeline systems, etc., can solve problems such as low work efficiency, corrosion of connectors, and difficulty in maintenance, so as to improve work efficiency and prevent liquid Leakage, the effect of reducing the difficulty of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

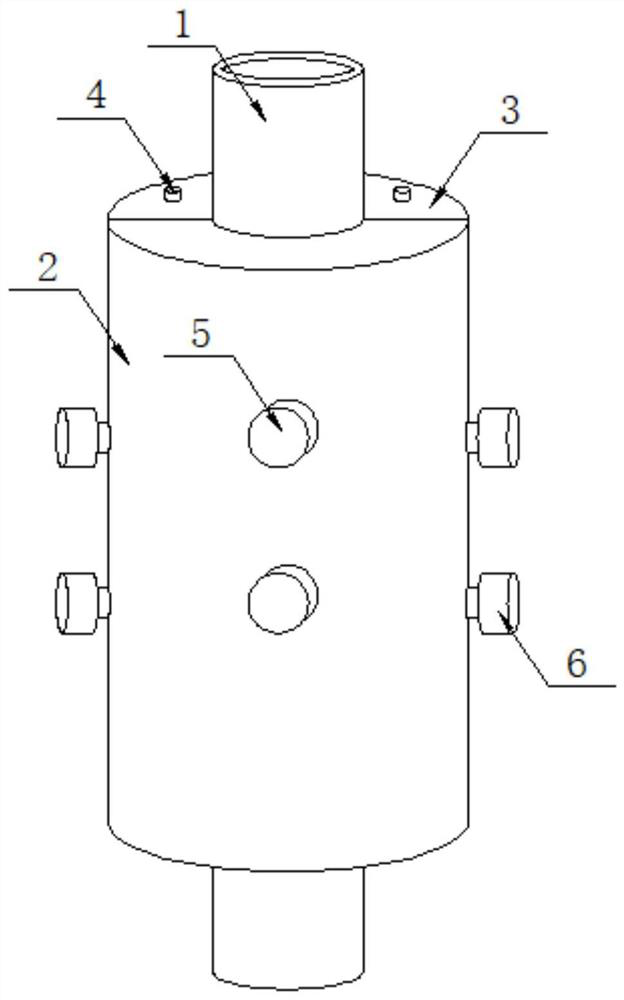

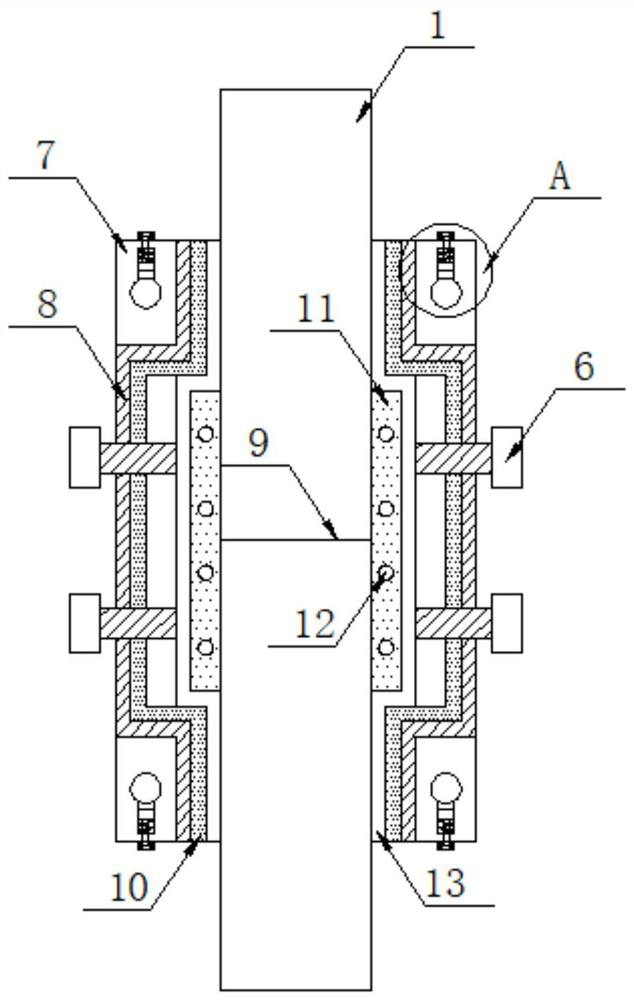

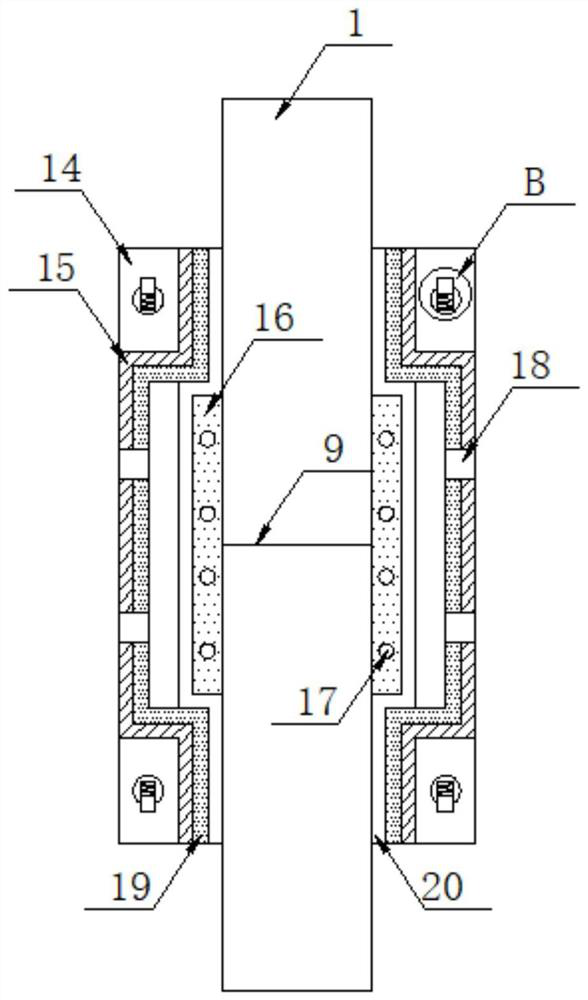

[0038] see Figure 1-8 , in an embodiment of the present invention, a water supply and drainage pipe anti-seepage device for construction engineering and an anti-seepage method thereof, comprising a water supply and drainage pipe 1, a first anti-seepage device 2 and a second anti-seepage device 3, the water supply and drainage pipe 1 is provided with Two, two connection points 9 are arranged between the two water supply and drainage pipes 1, and the first anti-seepage device 2 is arranged on one side of the connection point 9, and the outer surface of the first anti-seepage device 2 is fixed with a second anti-corrosion casing 15, and the second The anti-corrosion casing 15 effectively prevents the interior of the device from being corrupted and causes the anti-leakage effect to deteriorate. One side of the second anti-corrosion casing 15 is fixed with a second insulation layer 19, and the second insulation layer 19 insulates the joint 9 to prevent external ambient temperature ...

Embodiment 2

[0042] see Figure 1-8 , in an embodiment of the present invention, a water supply and drainage pipe anti-seepage device for construction engineering and an anti-seepage method thereof, comprising a water supply and drainage pipe 1, a first anti-seepage device 2 and a second anti-seepage device 3, the water supply and drainage pipe 1 is provided with Two, two connection points 9 are arranged between the two water supply and drainage pipes 1, and the first anti-seepage device 2 is arranged on one side of the connection point 9, and the outer surface of the first anti-seepage device 2 is fixed with a second anti-corrosion casing 15, and the second The anti-corrosion casing 15 effectively prevents the interior of the device from being corrupted and causes the anti-leakage effect to deteriorate. One side of the second anti-corrosion casing 15 is fixed with a second insulation layer 19, and the second insulation layer 19 insulates the joint 9 to prevent external ambient temperature ...

Embodiment 3

[0048] see Figure 1-8 , in an embodiment of the present invention, a water supply and drainage pipe anti-seepage device for construction engineering and an anti-seepage method thereof, comprising a water supply and drainage pipe 1, a first anti-seepage device 2 and a second anti-seepage device 3, the water supply and drainage pipe 1 is provided with Two, two connection points 9 are arranged between the two water supply and drainage pipes 1, and the first anti-seepage device 2 is arranged on one side of the connection point 9, and the outer surface of the first anti-seepage device 2 is fixed with a second anti-corrosion casing 15, and the second The anti-corrosion casing 15 effectively prevents the interior of the device from being corrupted and causes the anti-leakage effect to deteriorate. One side of the second anti-corrosion casing 15 is fixed with a second insulation layer 19, and the second insulation layer 19 insulates the joint 9 to prevent external ambient temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com