Gob-side entry retaining reinforced filling body structure and filling method thereof

A technology of filling body and roadway retention, which is applied in the direction of filling, earthwork drilling, safety devices, etc. It can solve the problems of poor flatness of the floor, crushing of the filling body, hidden safety hazards of the working face, etc., and achieve overall strength increase, The effect of increasing stability and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

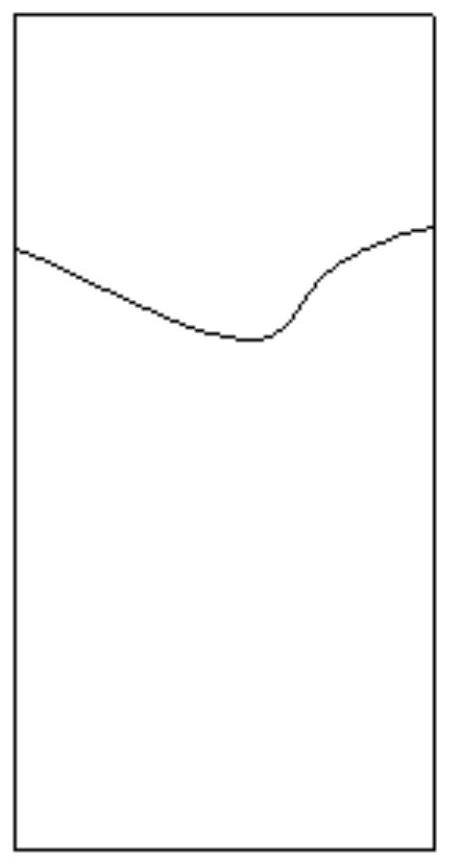

[0035]Such asfigure 1 The display shows the structure of the liquid surface of the existing roadway bypass filling body.

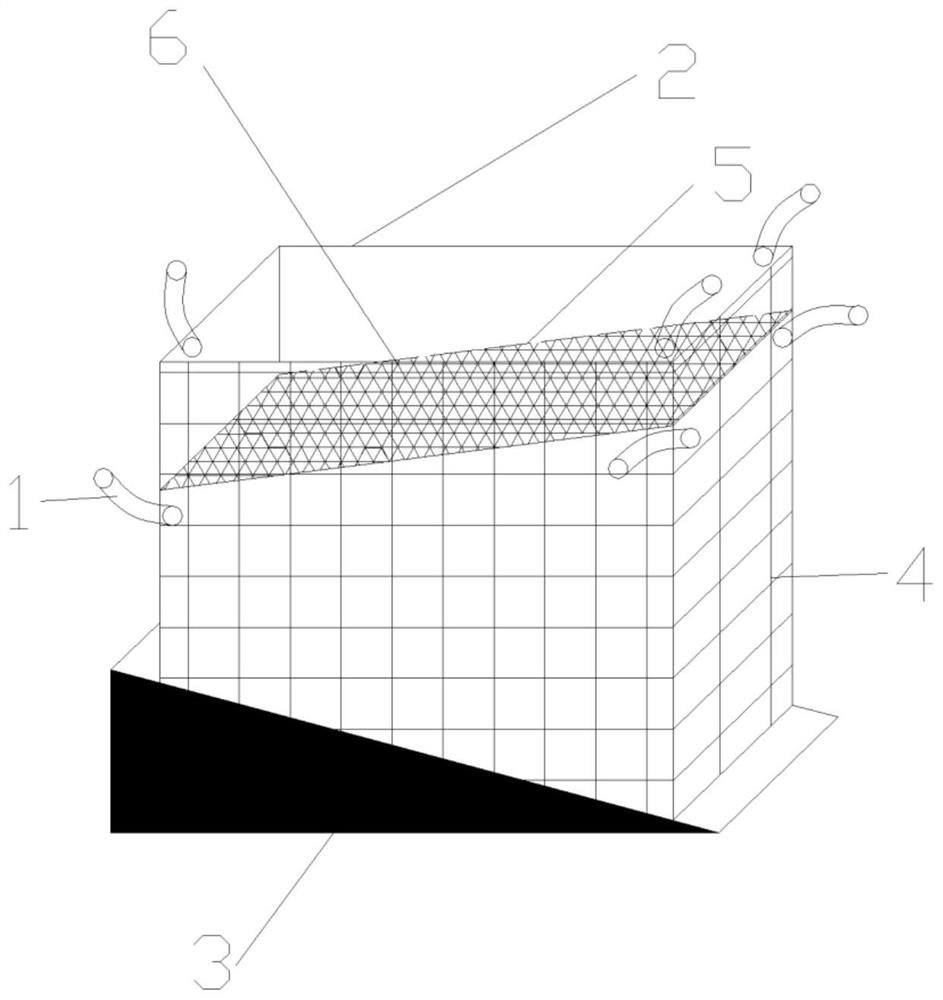

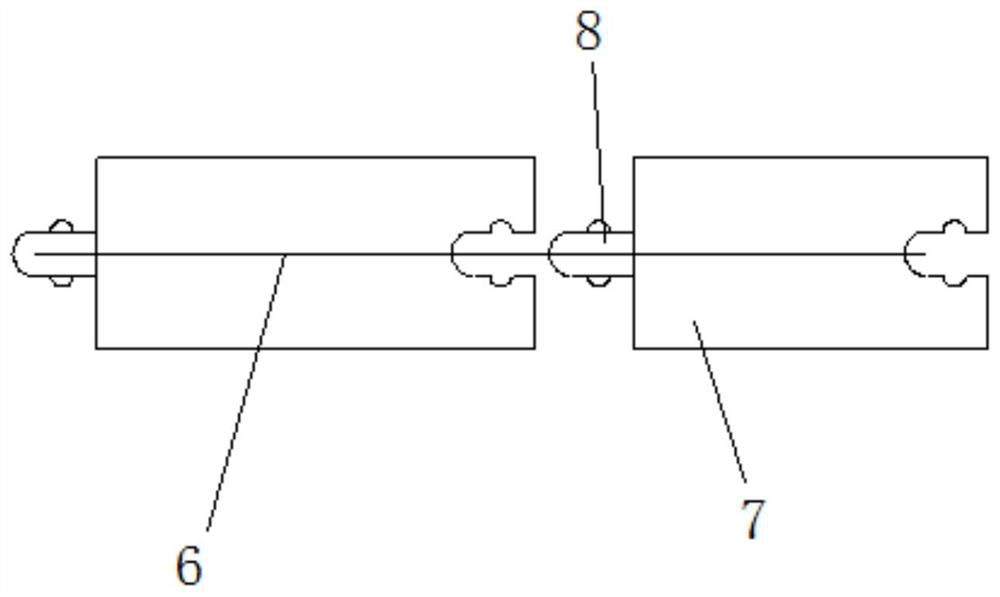

[0036]Such asfigure 2 As shown, a single laneside speedifier is overall view, in order to avoid the cross-axis of the pull-pull anchor on the left and right sides of the pattern complex. The laneside charging body is designed as an exterior of the outer table, which mainly includes two flies of the peripherals to total six filling ports, that is, the right side is filled in the grouting mouth, the left side is exhaust; filling The inside of the bag contains a carrier, carrying the wind cylindrical sewing above the backbone, so that the slurry of the lower two parts is isolated;

[0037]The inclination direction of the isolation unit is opposite to the bottom plate at the bottom of the filling bag;

[0038]The isolation unit is fixed to the filling bag and can be deformed with the supporting bag, and a spacer surface is formed, which separates the inner cavity of the fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com