Nuclear main pump mechanical seal key component size detection device

A technology of mechanical seal and nuclear main pump, which is applied to mechanical measuring devices, using mechanical devices, measuring devices, etc., can solve the problems that affect the safe and reliable operation of nuclear power plant reactors, and the measurement accuracy cannot meet the dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

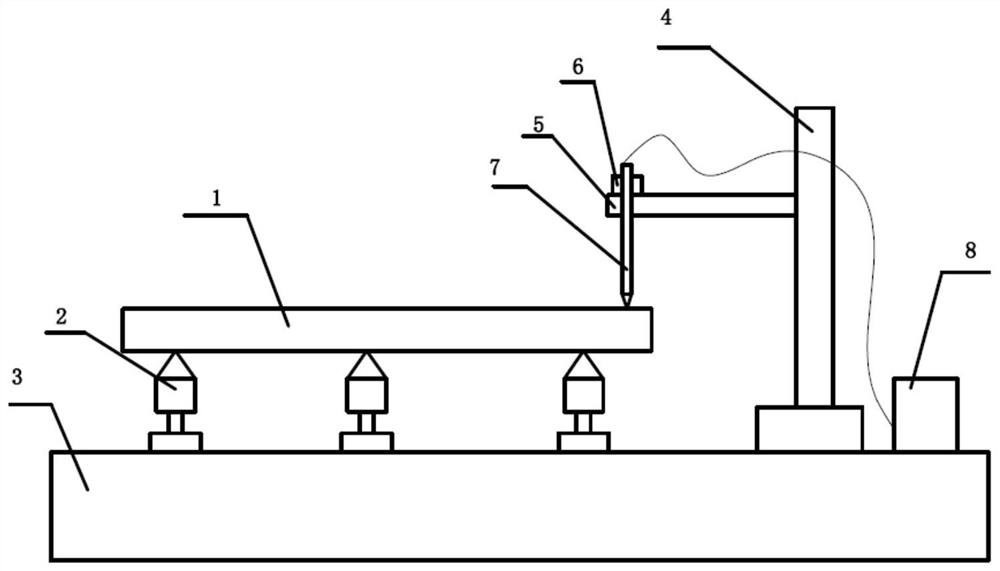

[0010] Such as figure 1 A detection device for the size of key components of the mechanical seal of a shaft-sealed nuclear main pump shown in 1. Three fine-tuning support frames 2 are installed on the marble platform 3, and the mechanical seal part 1 is installed on the three fine-adjustment support frames 2. High-precision sensing The measuring head 7 is located on the mechanical seal part 1, the high-precision induction measuring head 7 is installed on the spring lifting device 6, the spring lifting device 6 is fixed on the supporting beam 5, and the supporting beam 5 is installed on the mobile measuring pillar 4, the mobile The measuring pillar 4 is installed on the marble platform 3, and the high-precision display 8 and the high-precision inductive measuring head 7 are connected by data wires.

[0011] The present invention utilizes the fine-tuning support frame 2 to manually level the measuring workpiece. Use the compression spring of the spring lifting device 6 to press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com