A control system for encapsulating radioactive material containers in a sealed box

A technology of sealing the box and control system, which is applied in the general control system, control/regulation system, program control, etc., can solve the problems of operators being easily irradiated, slow operation, unsafe, etc., to avoid radiation pollution and ensure sealing performance, and the effect of improving packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

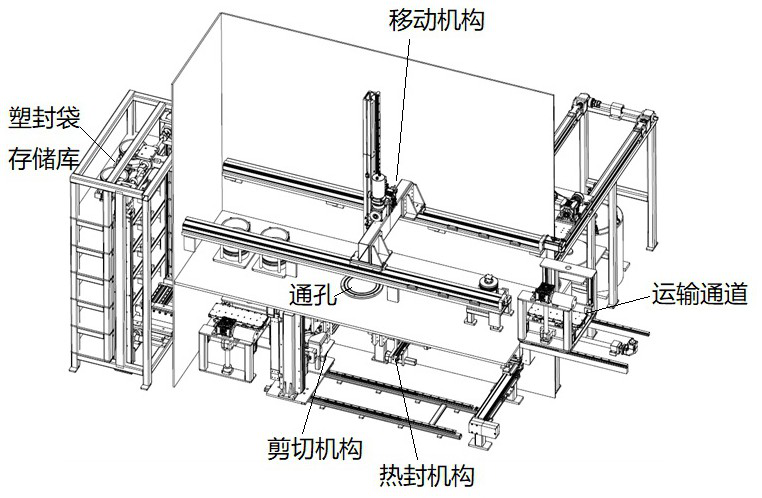

[0061] Such as figure 1 As shown, the embodiment of the present invention provides an automatic packaging system for realizing the packaging of radioactive material containers in a sealed box. The packaging system may include:

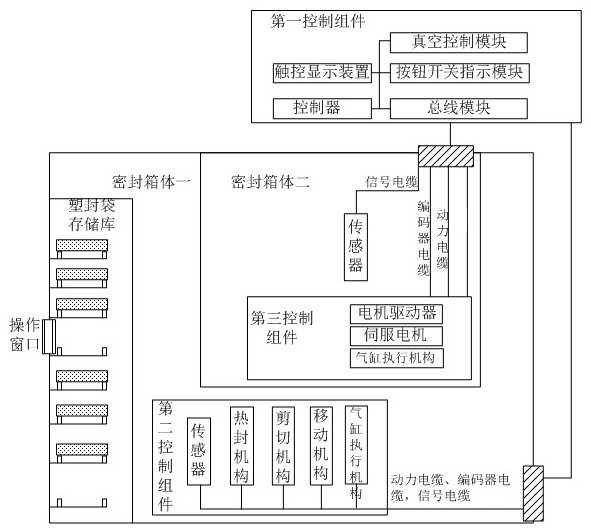

[0062] Sealed box 1, sealed box 2 nested inside sealed box 1, sealed box 1 and sealed box 2 are equipped with multiple mobile devices, the control system of the automatic packaging system includes: located in sealed box 1 The first external control assembly, the second control assembly located inside the first sealed box, and the third control assembly located inside the second sealed box.

[0063] exist figure 1 Both the moving device in the sealed box body 2 and the sealed box body 1 can include: a servo driver, a servo motor and a moving mechanism connected to the servo motor. For example, each moving device in the first sealed box includes: a first servo motor and a first servo driver; each moving device in the second sealed box includes: a secon...

Embodiment 2

[0095] Such as Figure 5 and Figure 6 As shown, the embodiment of the present invention provides a control method of the control system for realizing the sealing of the radioactive material container in the sealed box. The control method may include:

[0096] S1. When the controller determines that the radioactive material container is transferred to the designated area in the sealed box 2, it sends a first movement signal to the first moving device used to move the new plastic bag in the sealed box 1. Based on the first movement signal, the The plastic bag assembly carrying the new bag is nested on the outer edge of the station opening;

[0097] S2. The controller sends a second moving signal to the second moving device in the sealed box body 2 for moving the sealing cover of the station opening, so that the second moving device removes the sealing cover of the station opening based on the second moving signal so that station opening;

[0098] S3. The controller sends a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com