Method for preparing copper cartridge belt in self-propagating manner with assistance of supersonic vibration

A technology of ultrasonic vibration and copper elastic band, applied in welding equipment, manufacturing tools, aluminothermic welding equipment, etc., can solve problems such as high requirements for welders' operating level, large differences in physical and chemical properties, and arc radiation pollution. , to reduce production time and workload, reduce belt defects, and improve productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

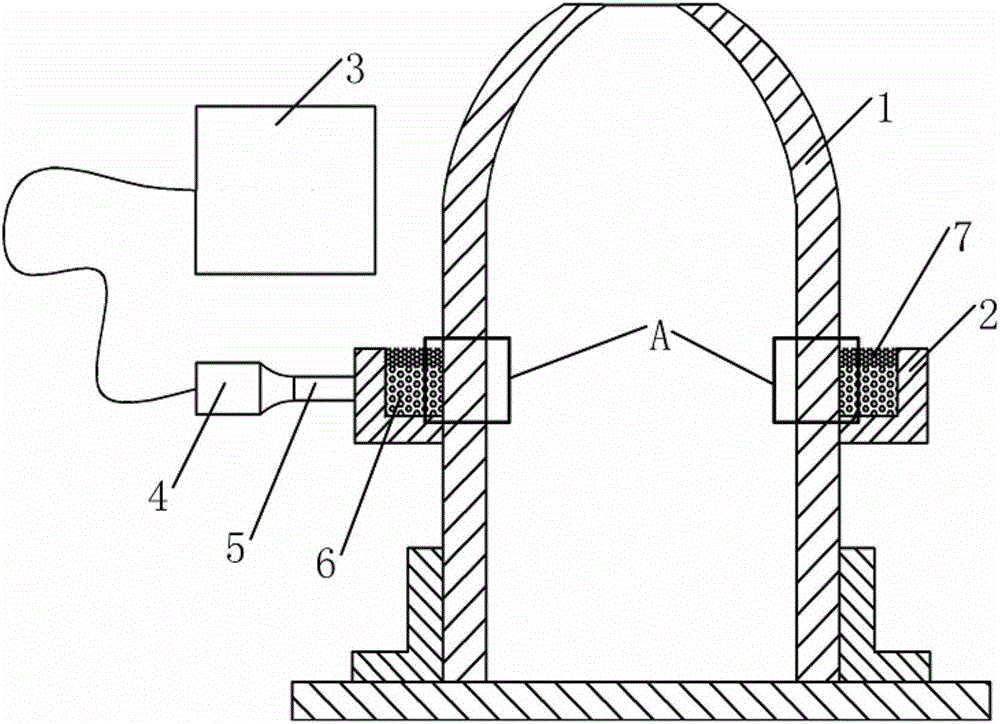

[0018] Specific implementation mode one: combine figure 1 Describe this implementation mode, this implementation mode is realized through the following steps:

[0019] Step 1: Set the annular cylindrical graphite crucible 2 on the outer diameter position A of the copper shell 1, and seal the gap between the annular cylindrical graphite crucible 2 and the copper shell 1 with yellow mud to ensure the accuracy and safety of the belt production ;

[0020] Step 2: Connect the ultrasonic generator 3 with the ultrasonic introduction device 4, and fix the tool head 5 on the ultrasonic introduction device 4 on the ring-shaped graphite crucible 2, so as to ensure good connection between each device;

[0021] Step 3: uniformly mixing aluminum powder and copper oxide powder to obtain the thermite reactant 6, and putting the thermite reactant 6 into the annular cylindrical graphite crucible 2;

[0022] Step 4: Turn on the ultrasonic generator 3 and the ultrasonic introduction device 4, t...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 1 Illustrate present embodiment, present embodiment is that the inner diameter of the annular cylindrical graphite crucible 2 in the step 1 is determined according to copper shell 1 diameter, and the diameter of copper shell 1 is bigger, and the diameter of copper bullet belt is bigger, and required aluminum powder and The more copper oxide powder there is, the higher the height of the annular cylindrical graphite crucible 2 is. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 This embodiment is described. In this embodiment, the tool head 5 that transmits ultrasonic vibration in step 2 is fixed at the central position of the height of the annular cylindrical graphite crucible 2 . Other steps are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com