Pulse type liquid-solid two-phase flow erosive wear test device in airflow jet environment

An air jet and wear test technology, applied in the direction of measuring devices, wear resistance testing, instruments, etc., can solve the problems of high cost, large research and development costs, and the inability to realize high-speed liquid-solid two-phase flow erosion, etc., to achieve responsiveness, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

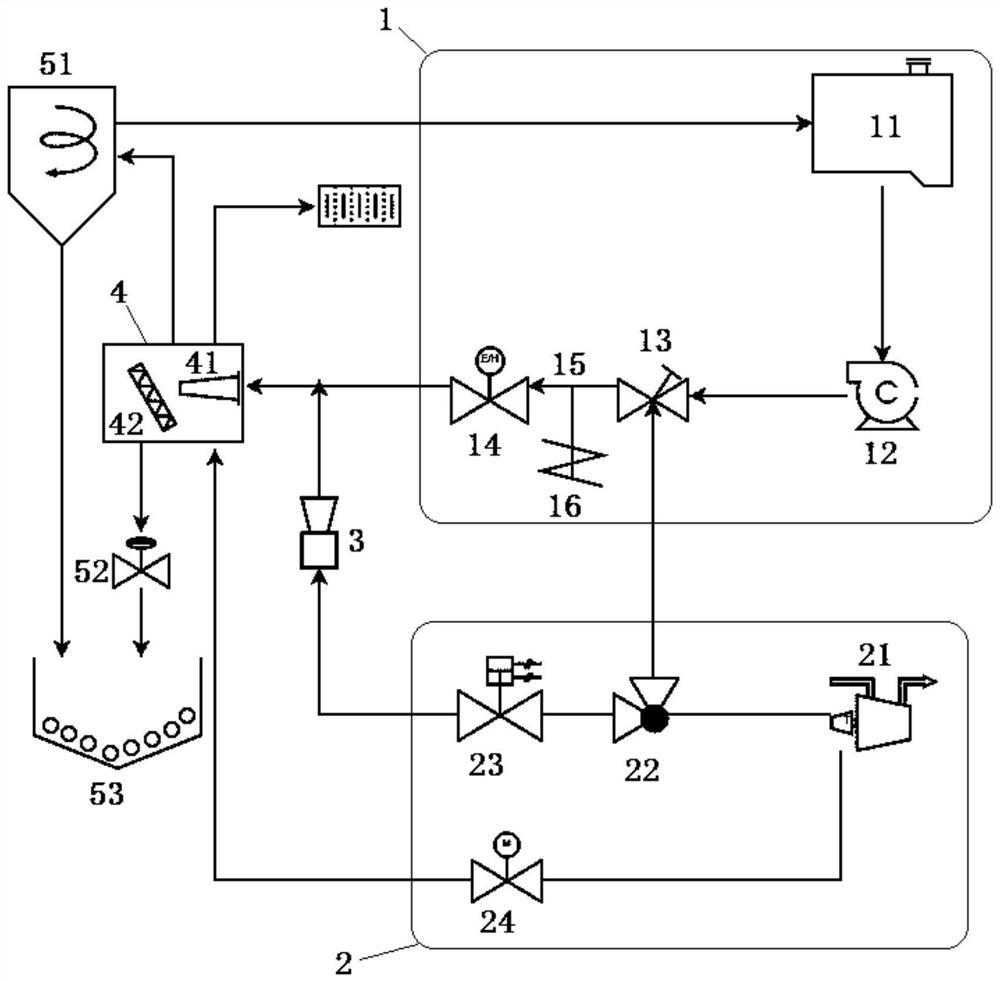

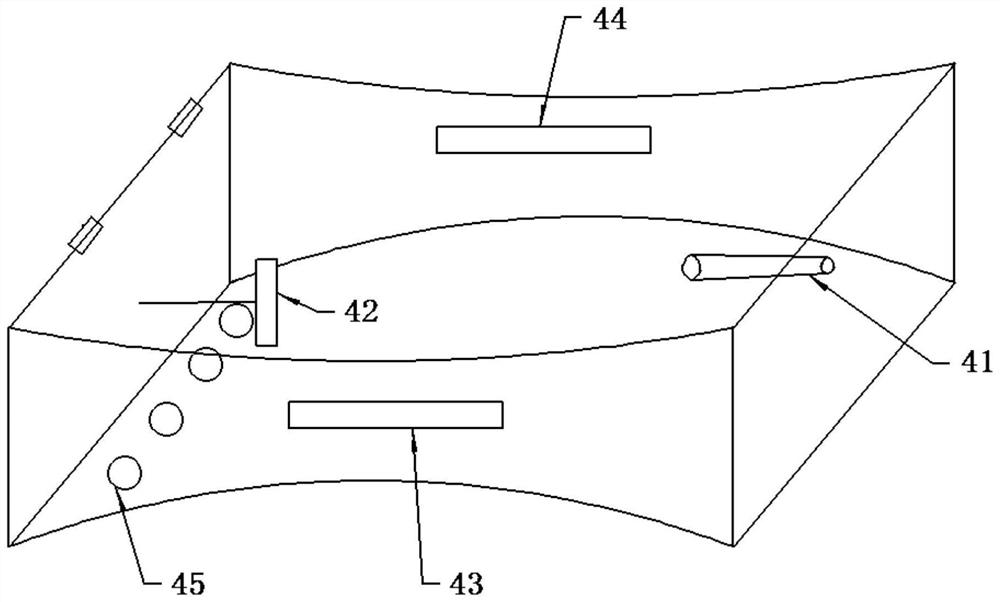

[0023] Example: A pulsed liquid-solid two-phase flow erosion wear test device in an air jet environment, the structure is as follows figure 1 and figure 2 As shown, it includes a water supply module 1, an air supply module 2, a particle loading device 3 and an erosion test chamber 4; the water supply module 1 provides a high-speed liquid flow for the erosion and wear test, and includes a water tank 11, a centrifugal pump 12, Pneumatic angle seat valve 13 and throttle valve 14, the pneumatic angle seat valve 13 forms a pressure wave at the outlet using the water hammer phenomenon formed when it is closed, and the pressure wave is transmitted to the throttle valve 14 to form a high-speed liquid flow, so The outlet of the throttle valve 14 is connected with the erosion test chamber 4; the air supply module 2 provides an air source for the pneumatic angle seat valve 13, the erosion test chamber 4, and the particle loading device 3, respectively making the pneumatic angle seat Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com