Control system of electric shunt valve and control method thereof

An electric water diversion valve and control system technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems of cramped bathtub space, water pressure loss, noise, etc., and achieve precise control, simplified operation, The effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A control system and a control method of an electric water diverter valve provided by the present invention will be further described below with reference to the accompanying drawings. It should be pointed out that the technical solution and design principle of the present invention are only described below with an optimized technical solution. elaborate.

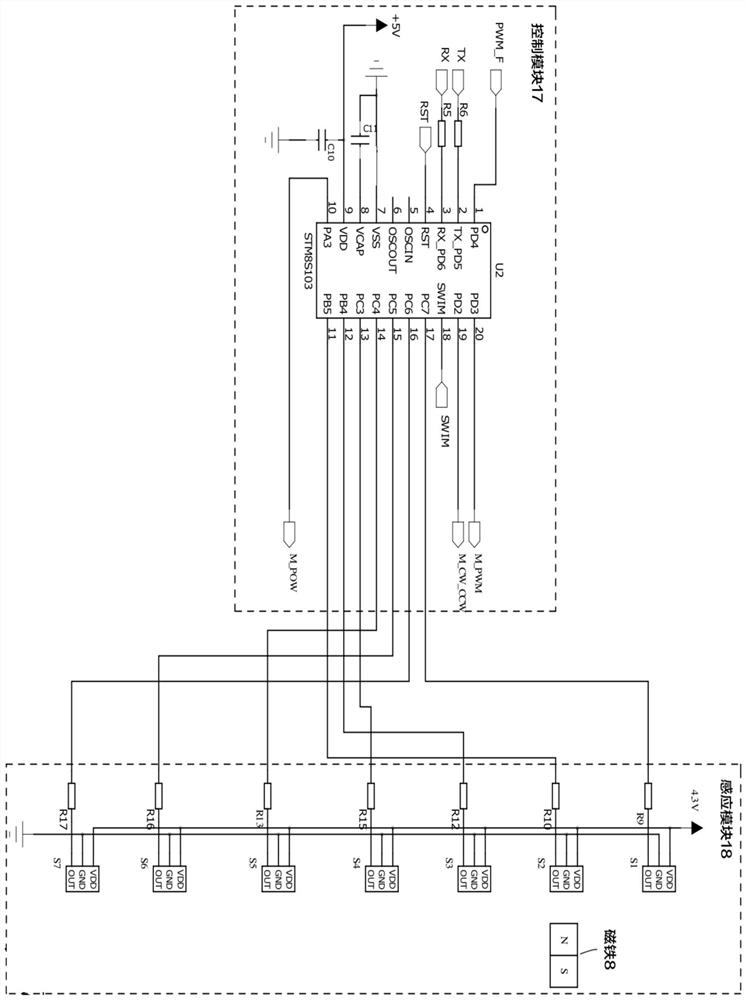

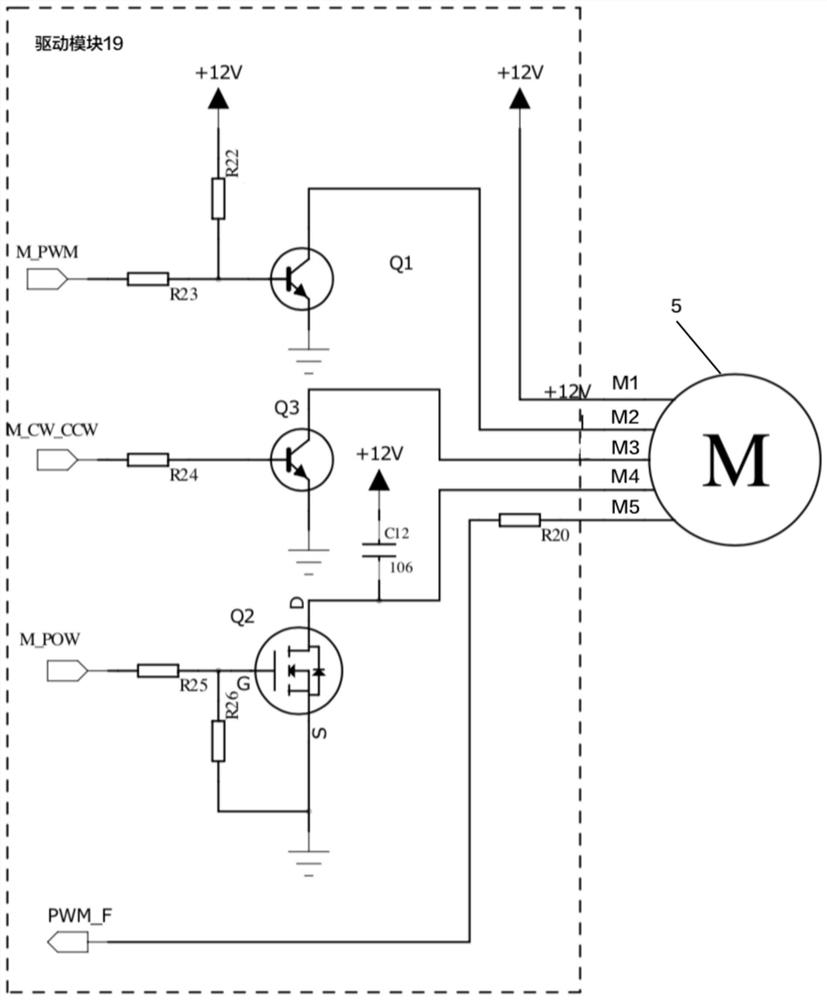

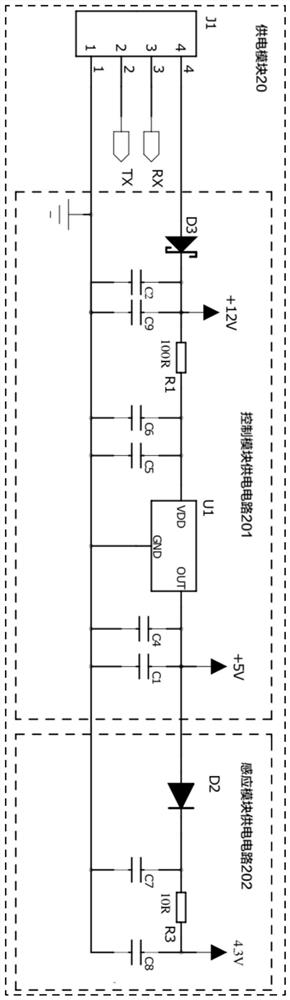

[0045] see figure 1 , figure 2 and image 3 The present invention provides a control system for an electric water diverter valve, comprising a power supply module 20, a control module 17, an induction module 18 and a drive module 19, wherein the power supply module 20 is electrically connected to the control module 17, The power supply module 20 is used to provide power to the control module 17 and the induction module 18; the control module 17 is also electrically connected to the induction module 18 and the driving module 19, and the control module 17 is used to provide the driving module 19 according to the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com