Integrated production device for semi-finished steak product

A technology for production equipment and semi-finished products, which is applied in the field of integrated production equipment for cutlets and semi-finished products, can solve the problems of low efficiency and manpower consumption, and achieve the effects of high automation, improved efficiency, and high-quality processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

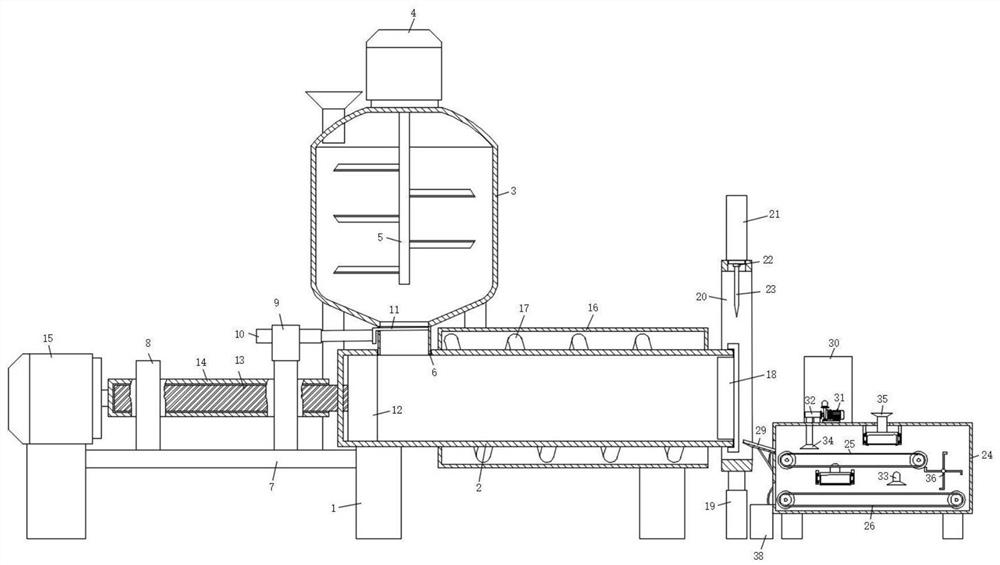

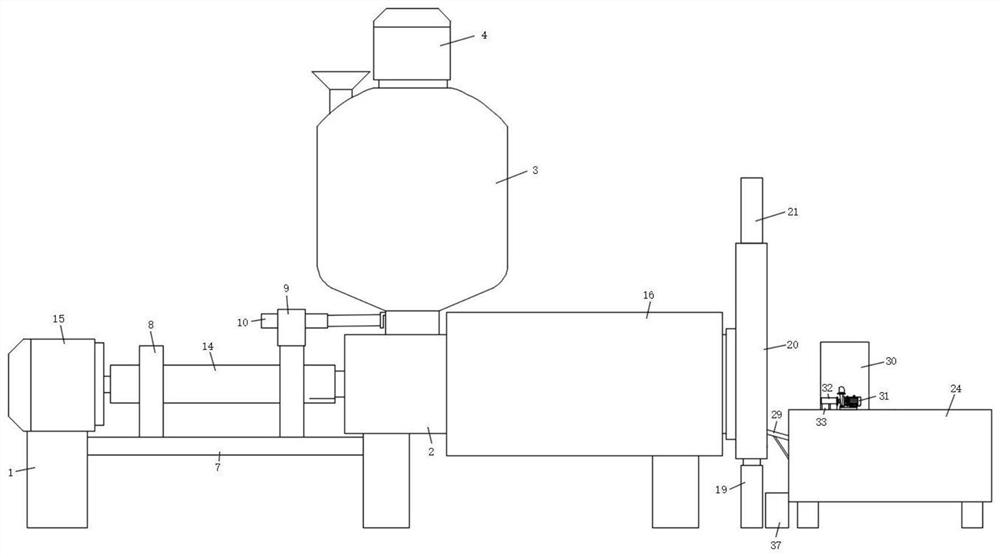

[0029] refer to Figure 1-5, an integrated production equipment for semi-finished meat steaks, including a mounting base 1, three mounting bases 1 are provided and fixed on the working surface, the top of the mounting base 1 in the middle is fixed with a pressing plate 2 through screws, and one side of the upper end of the pressing plate 2 A crushing barrel 3 is provided, and the top surface of the crushing barrel 3 is fixed with a servo motor 4 through screws. There is also a feeding funnel connected through it, and a material guide pipe 6 is connected between the bottom surface of the crushing barrel 3 and the pressing dish 2, and a support plate 7 is fixedly connected between the two mounting seats 1 on one side, and the two top surfaces of the support plate 7 The sides are welded with support base 8, and the top surface of support base 8 near the crushing bucket 3 side is also fixedly connected with a mounting block-9, and the inner side of the mounting block-9 is fixedly ...

Embodiment 2

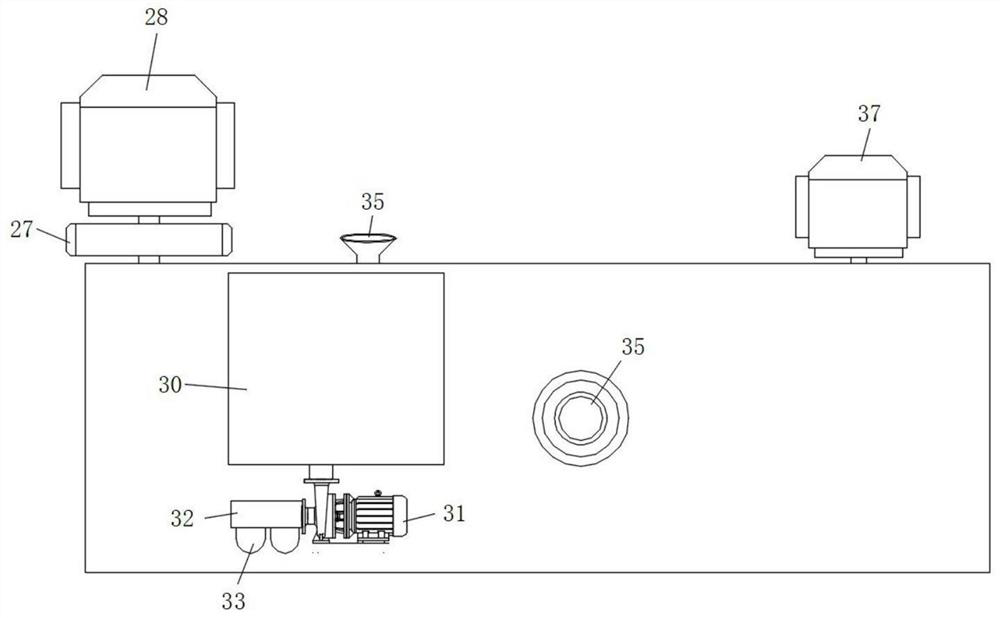

[0032] Such as figure 1 , 2 As shown in and 5, this embodiment is basically the same as Embodiment 1. Preferably, the sprinkling mechanism 35 includes a sprinkling box 351, and the top of the sprinkling box 351 is connected with a feeding funnel 352, and the connection between the feeding funnel 352 and the feeding box body 24 There is an even gap connection between them, and both sides of the sprinkling box 351 are provided with fixed plates 353, and the fixed plates 353 are fixed on the inner walls of the front and rear sides of the feeding box 24, and both sides of the outer walls of the sprinkling box 351 are fixedly connected with sliding blocks 354. The fixed plate 353 is also provided with a sliding groove near one end of the sprinkling box 351, and the sliding block 354 is slidably connected in the sliding groove, and an elastic member 355 is fixedly connected between the sliding block 354 and the top surface and the bottom surface of the sliding groove, and the sprink...

Embodiment 3

[0035] Such as figure 1 and 2 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the crushing barrel 3 is fixed on the support plate 7 and the top surface of the condensation barrel 16 through a support column.

[0036] In this embodiment, the crushing barrel 3 is fixedly connected to the support plate 7 and the top surface of the condensation barrel 16, so that the meat is more stable when crushed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com