Clean bench capable of realizing continuous sterilization

A technology for ultra-clean workbenches and workbenches, which is applied in the direction of laboratory stools/lab benches, sanitary equipment for toilets, buildings, etc. It can solve the problems that ultraviolet sterilization is difficult to complete, and experimental operations cannot be carried out in real time, so as to achieve saving Effect of UV sterilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

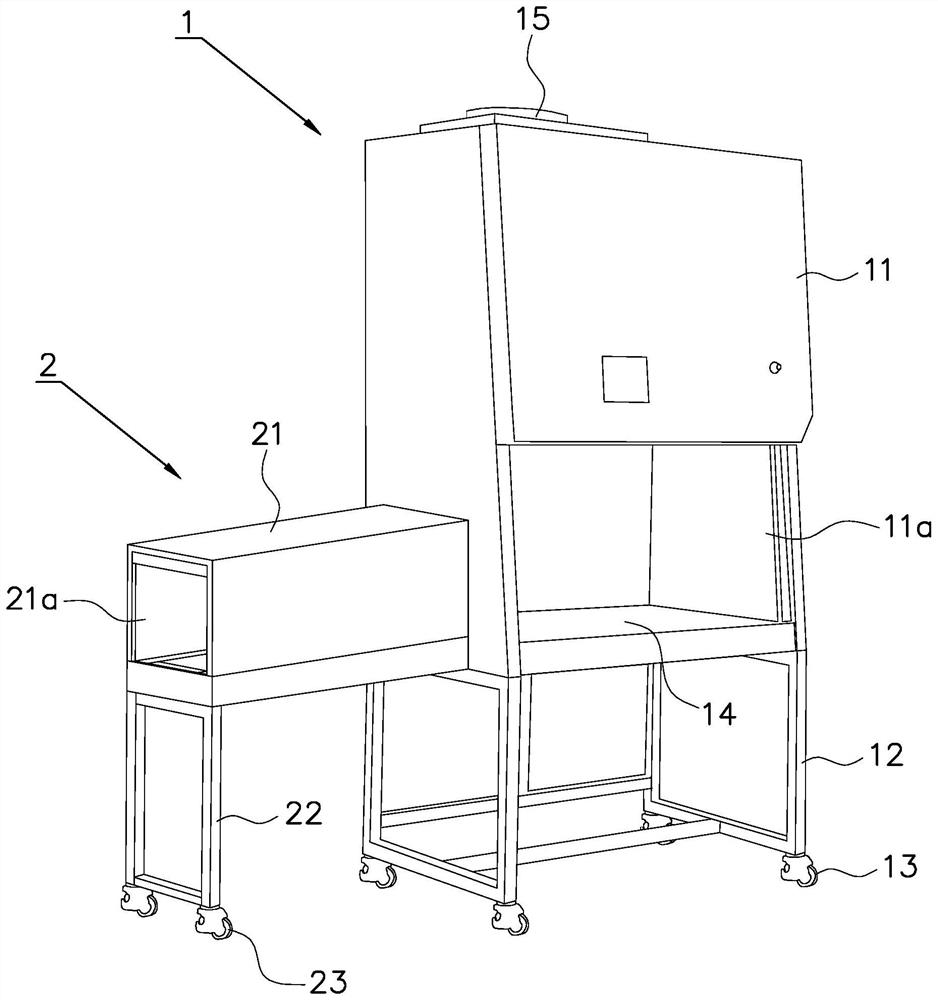

[0037] like figure 1As shown, a continuous sterilization ultra-clean workbench in this embodiment includes a host 1, and the host 1 includes a frame 11, and the support seat 12 at the bottom of the frame 11 has universal wheels 13 to facilitate the movement of the whole machine; the frame 11 A worktop 14 is arranged inside, and one of the side walls of the worktop 14 is provided with an operation window 11a, and glass (not shown) that can be pushed and pulled up and down is installed at the operation window 11a; There are 15 blowers. The host machine 1 in this embodiment is consistent with the traditional ultra-clean workbench in the prior art, so this embodiment will not repeat it.

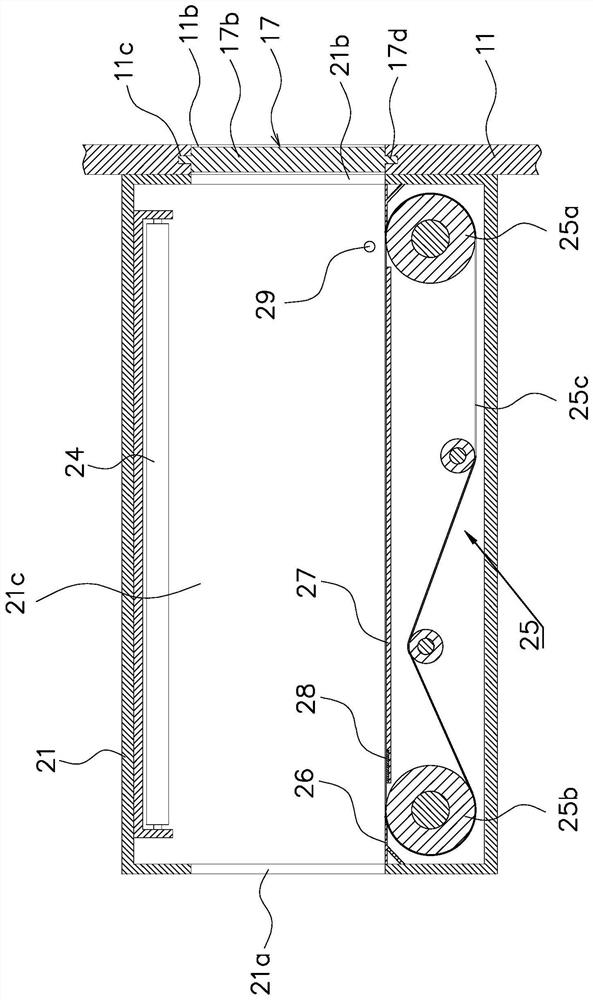

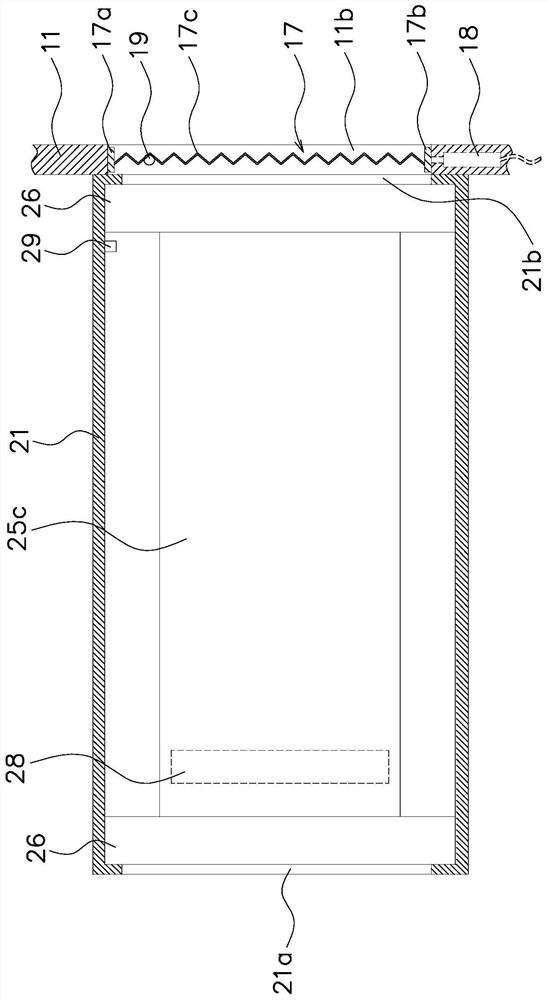

[0038] Such as figure 1 As shown, in this embodiment, an auxiliary sterilization device 2 is provided on one side of the host computer 1 adjacent to the operation window 11a. Such as figure 2 and image 3 As shown, the auxiliary sterilization device 2 includes a casing 21, the bottom of the...

Embodiment 2

[0050] Such as Figure 5 As shown, a continuous sterilization ultra-clean workbench in this embodiment includes a host 1 and an auxiliary sterilizing device 2, the host 1 and the auxiliary sterilizing device 2 are the same as those in Embodiment 1, the difference is that in addition to the operation window Outside the side where 11a is located, among the other three sides of the frame 11 of the host 1, at least two sides are provided with receiving windows 11b, and each receiving window 11b is sealed with an auxiliary sterilization device 2.

Embodiment 3

[0052] Such as Figure 6 As shown, the present embodiment is a continuous sterilization ultra-clean workbench, including a host 1 and an auxiliary sterilization device 2. Outside the side where 11a is located, among the other three sides of the main frame 11, at least two sides are provided with receiving windows 11b, and each receiving window 11b is sealed and connected with an auxiliary sterilizing device 2; and there is at least one The sterilization inlet 21 a and the sterilization outlet 21 b of the auxiliary sterilization device 2 are respectively sealed and docked with the two hosts 1 , so as to realize the aseptic transfer of articles between the two hosts 1 .

[0053] At this time, at the receiving window 11b of the host that is sealed and docked with the sterilization entrance 21a, an electric control switch can also be set to control the opening and closing of the glass door at the sterilization entrance 21a; of course, it can also be opened and closed manually.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com