Heavy truck hub bearing unit comprehensive cleaning machine

A technology for wheel hub bearings and washing machines, which is applied to dryers, cleaning methods and utensils, and cleaning methods using liquids, etc., can solve problems such as unclean surface of wheel hub bearings, achieve good water stain treatment effect, convenient maintenance, High cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

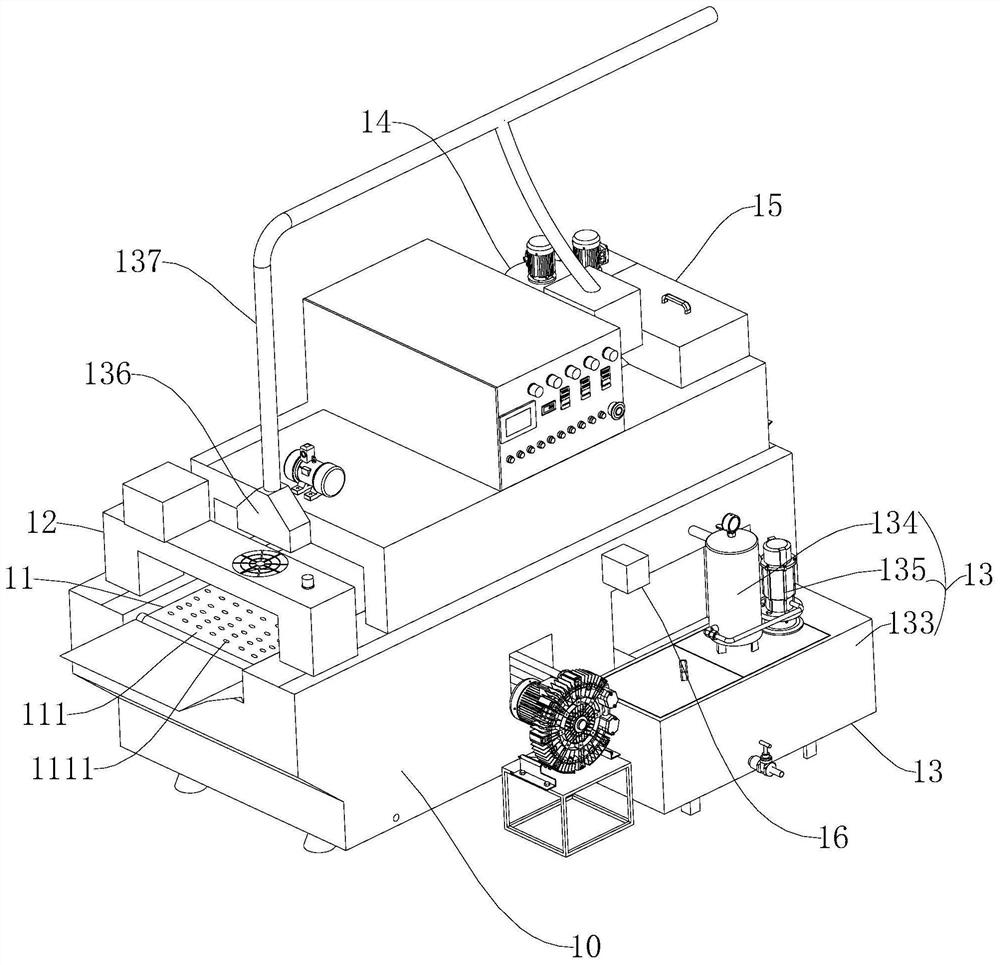

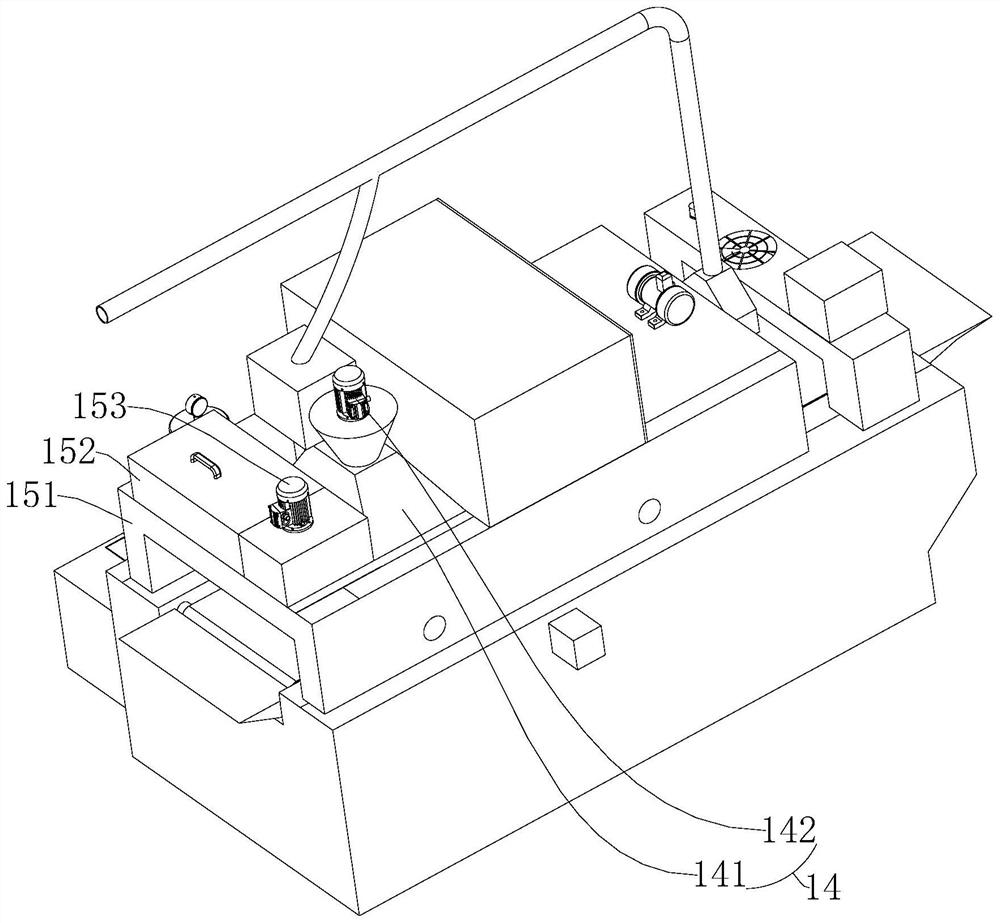

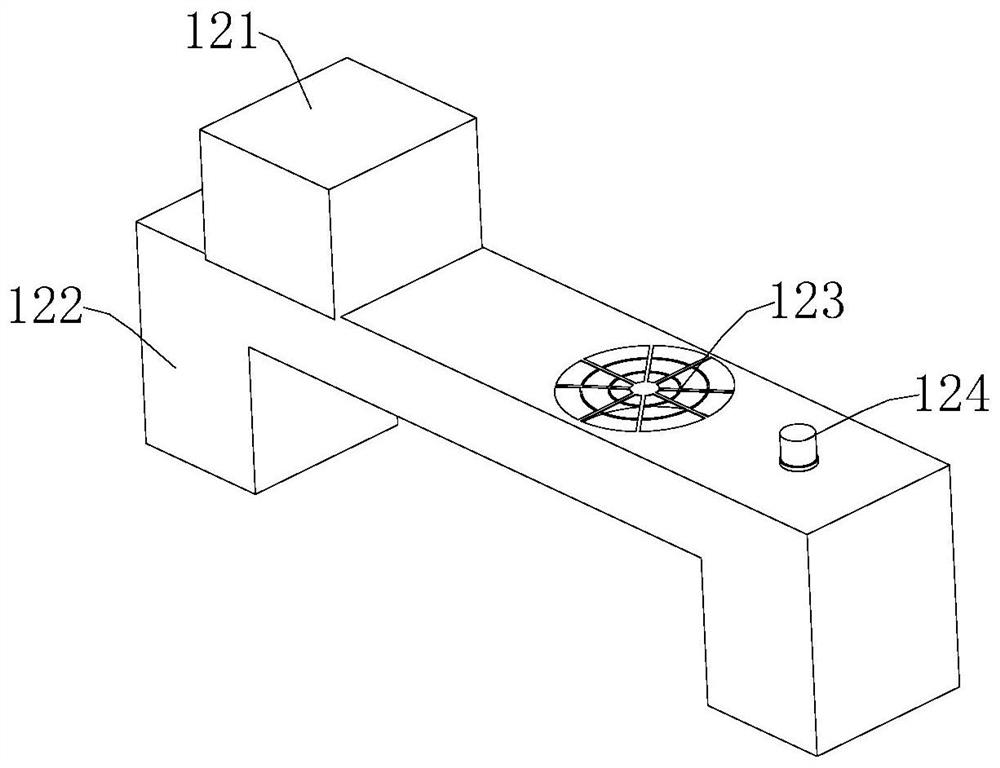

[0029]A comprehensive cleaning machine for heavy truck hub bearing units, comprising a body 10, on which a conveying mechanism 11, a degaussing mechanism 12, a cleaning mechanism 13, a drying mechanism 14, an oil injection mechanism 15, a degaussing mechanism 12, a cleaning mechanism 13, a drying Drying mechanism 14 and fuel injection mechanism 15 are all located on the top of conveying mechanism 11 and arranged in sequence along its conveying direction, conveying mechanism 11 quantity is two; The first water spot removal device 161 for removing water stains on the bottom surface and the top surface of the wheel hub bearing and the second water spot removal device 162 for removing water stains on the sides of the wheel hub bearing, the first water spot removal device 161 includes a water stain removal assembly and the water stain removal assembly, the water stain removal assembly is arranged between the drying mechanism 14 and the oil spray mechanism 15, the water stain removal...

Embodiment 2

[0041] Embodiment 2 has basically the same features as Embodiment 1, the difference is that the lifting frame 1621 is a square lifting frame, a pair of opposite corners of the lifting frame 1621 is equipped with a second cylinder, and the other pair of diagonal corners of the lifting frame 1621 is equipped with a guide Rods and guide rods are erected on both sides of the conveying mechanism 11 and connected with the body 10, and the lifting frame 1621 moves up and down along the guide rods.

Embodiment 3

[0043] Embodiment 3 has basically the same features as Embodiment 1, except that the cleaning mechanism 13 also includes a dust suction fan 136 for absorbing impurities on the hub bearing, and the dust suction fan 136 is connected with a ventilation duct 137, and the air outlet of the dust suction fan 136 It is provided in the degaussing mechanism 12 and the rough cleaning nozzle assembly 131 . Before water washing, the larger impurities on the wheel hub bearings are sucked by the dust suction fan 136, so that the larger impurities will not remain in the cleaning liquid box 133 during washing, which effectively prevents the impurities from clogging the filter 134. The service life of the filter 134 is improved. After the wheel hub bearing passes through the degaussing process, the workpiece first enters the dust collection process, and the workpiece comes to the position of the dust suction fan 136. The dust suction pipe 137 is connected to a debris recovery box. After the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com