Secondary ejection die casting die

A die-casting mold and secondary ejection technology, applied in the field of die-casting molds, can solve the problems of reducing the force of ejection, reducing the quality of die-casting products, reducing flexibility, etc., so as to enhance the force of ejection and enhance the effect of ejection , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

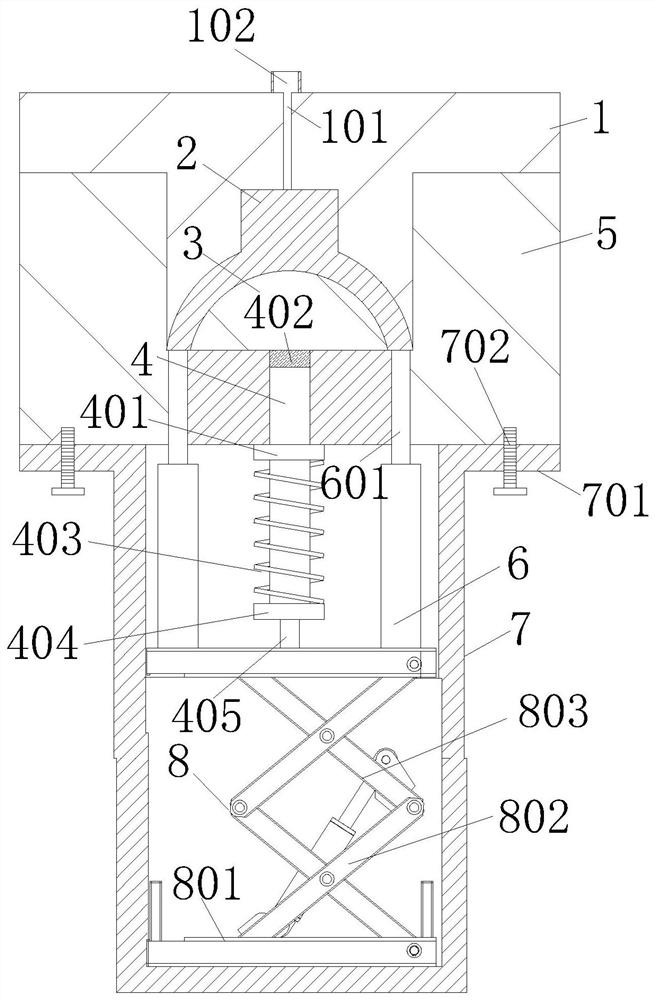

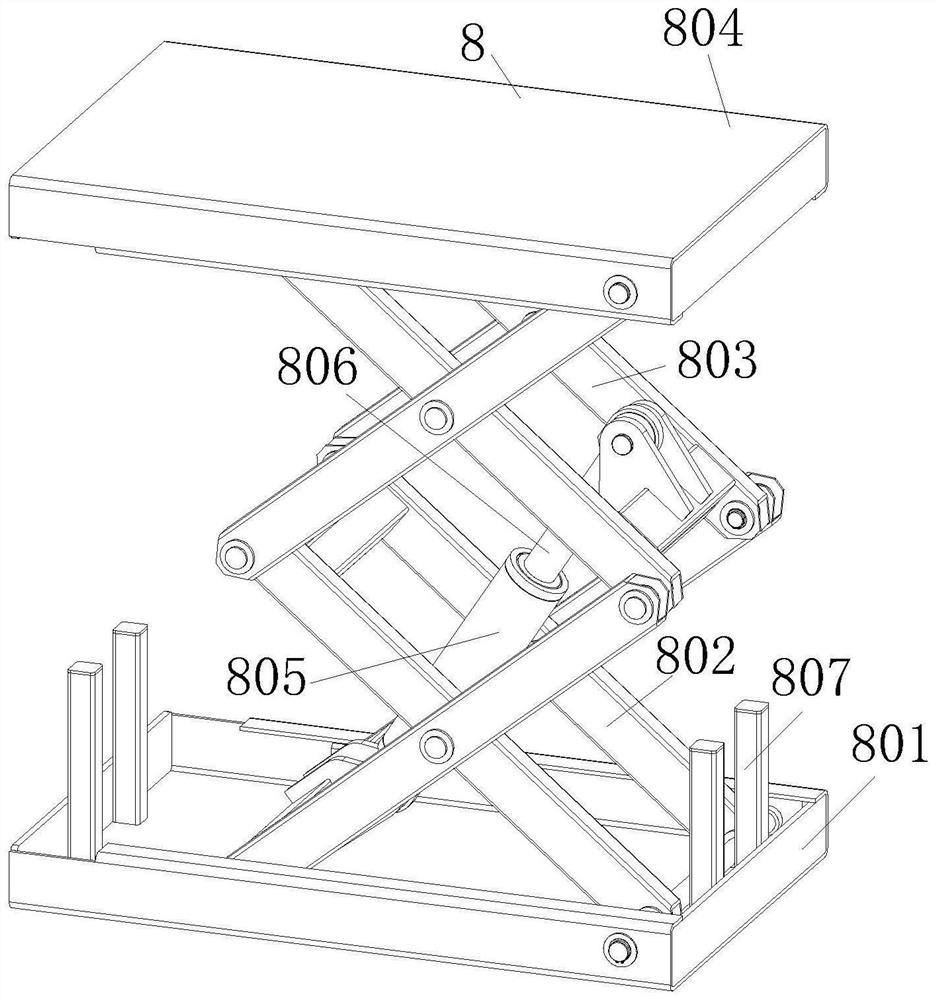

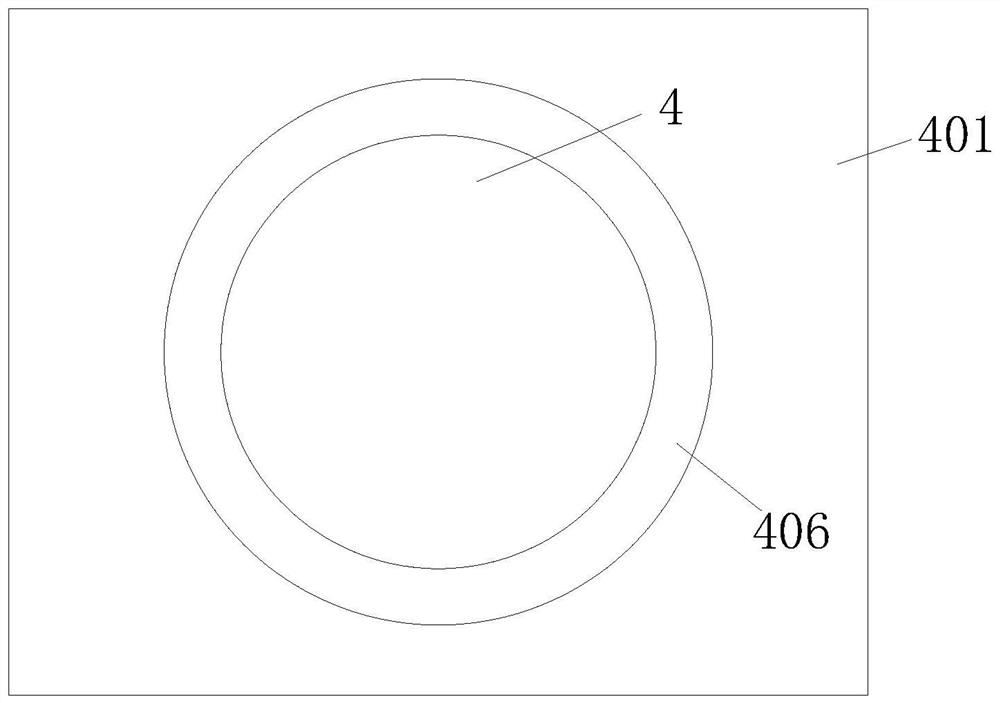

[0024] Such as Figure 1-Figure 3 As shown, a secondary ejection die-casting mold according to the present invention includes a fixed module 1, a movable mold assembly 5, a first hydraulic cylinder 4, an installation frame 7, and a lifting assembly 8, and the center of the top of the fixed module 1 is provided with a filling Liquid channel 101, liquid filling port 102 is provided on the upper side of liquid filling channel 101, movable mold assembly 5 is arranged on the bottom of fixed module 1, and core 3 is arranged on the upper part of movable mold assembly 5, and the gap between core 3 and fixed module 1 There is a die-casting part 2 between them, the first hydraulic cylinder 4 is slidably fitted in the movable mold assembly 5, the installatio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap