Welding edge saw blade milling cutter with replaceable saw blade

A saw blade milling cutter and saw blade technology, applied in the field of tools, can solve the problems of loss, large tool setting error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

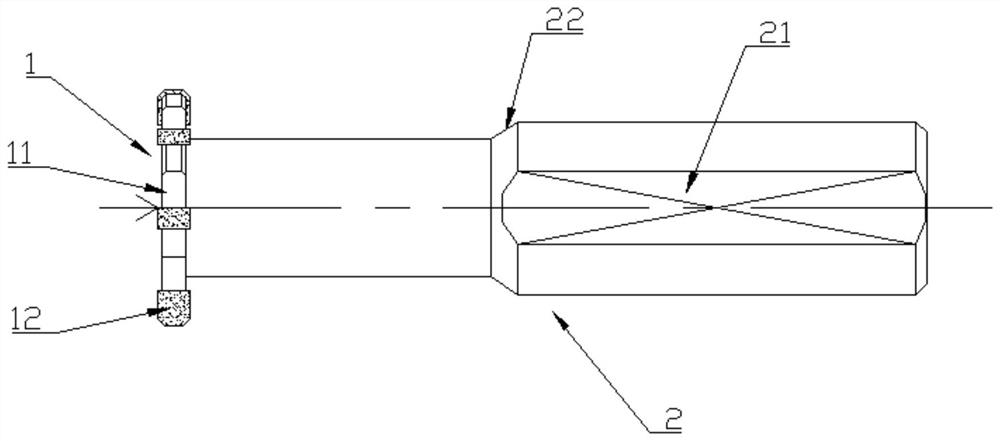

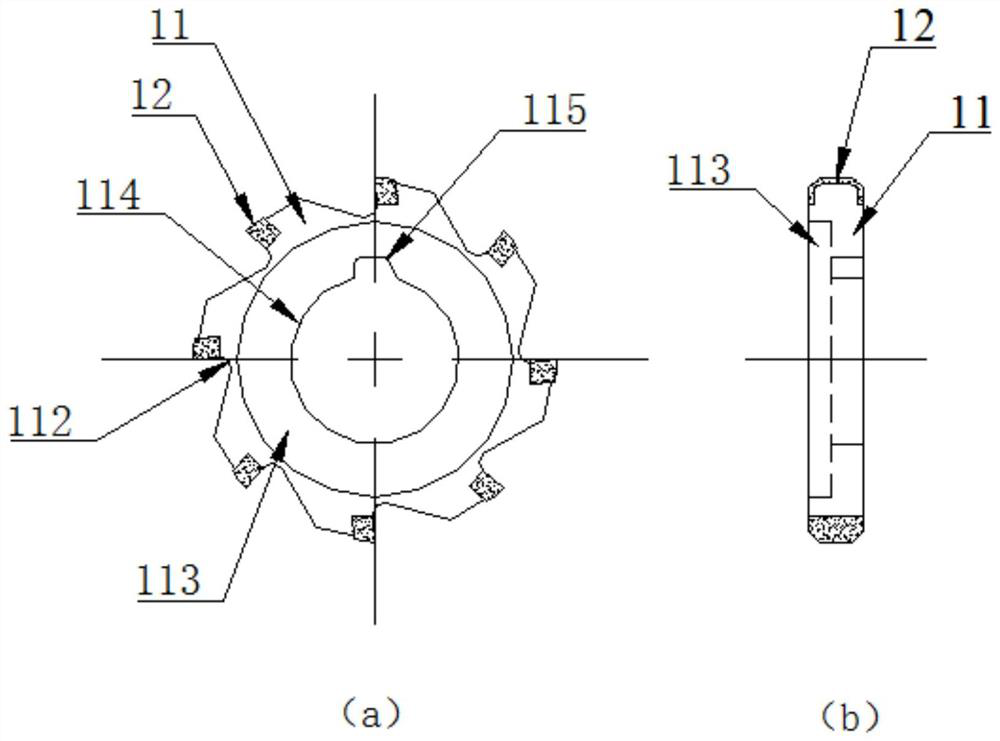

[0021] Such as Figure 1-5 Shown is a welded blade milling cutter with a replaceable saw blade, a saw blade 1 and a handle 2, the saw blade and handle 2 are fixed by a compression nut 3, and the saw blade 1 includes a base 11 and a blade 12. Eight sipe grooves 111 are equally divided on the outer side of the base body 11 , and a blade 12 is welded on each sipe groove 111 , and a groove bottom 112 is provided inside the sipe groove 111 .

[0022] In this embodiment, a counterbore 113 and a mounting hole 114 are provided inside the base 11 , the counterbore 113 is provided outside the mounting hole 114 , and a keyway 115 is provided on the mounting hole 114 .

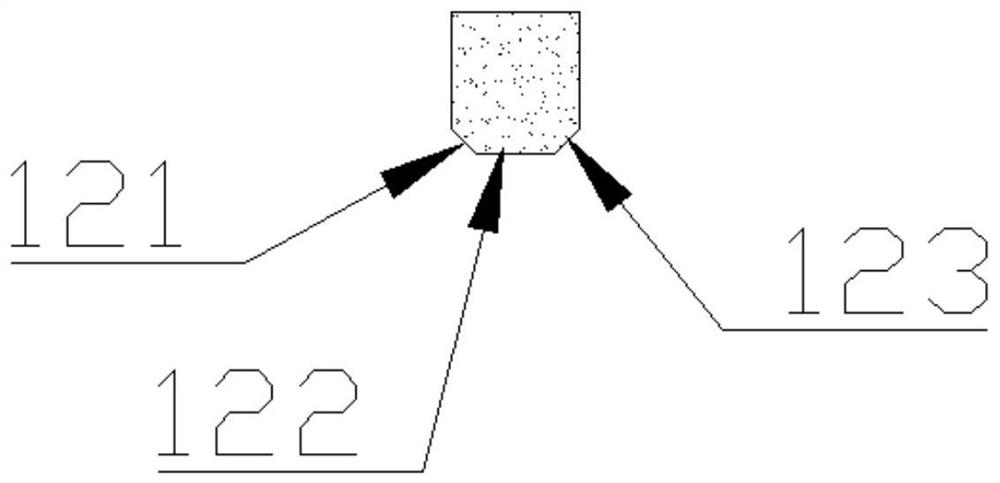

[0023] In this embodiment, the blade 12 is provided with a rake angle a, a first relief angle b, and a second relief angle c, the rake angle a is 5° to 7°, and the first relief angle b is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com