Spindle broach device and turret type numerical control milling machine

A tool device and spindle technology, applied in the field of machine tools, can solve the problems of tool machine tool coordinate Z value deviation, affect efficiency, easily damaged thread ejector, etc., and achieve the effect of tool change accuracy and speed improvement, tool change convenience, and accuracy improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

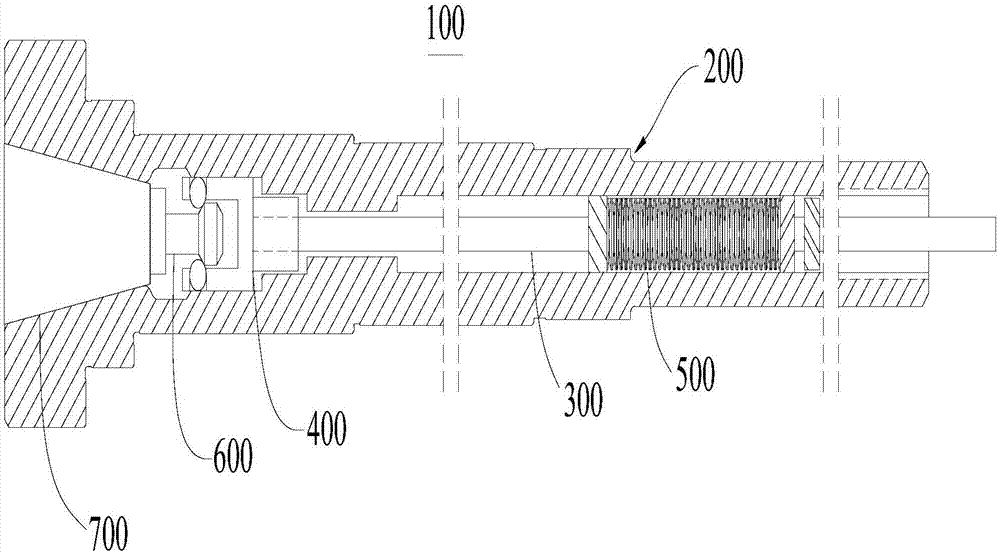

[0033] A turret type CNC milling machine (not shown), on which a milling machine base, a milling machine bed, a workbench, a milling machine column, a milling head and a main shaft broaching device 100 ( figure 1 shown), the milling machine bed is set on the milling machine base, the workbench is set on the milling machine bed, the lower end of the column is connected to the milling machine bed, the upper end of the column is connected to the milling head, and the spindle broaching device 100 is set on the milling head, wherein the milling machine Base, milling machine bed, workbench, milling machine column, milling head are not the core of the present invention, those skilled in the art can realize by referring to the prior art, do not repeat them here.

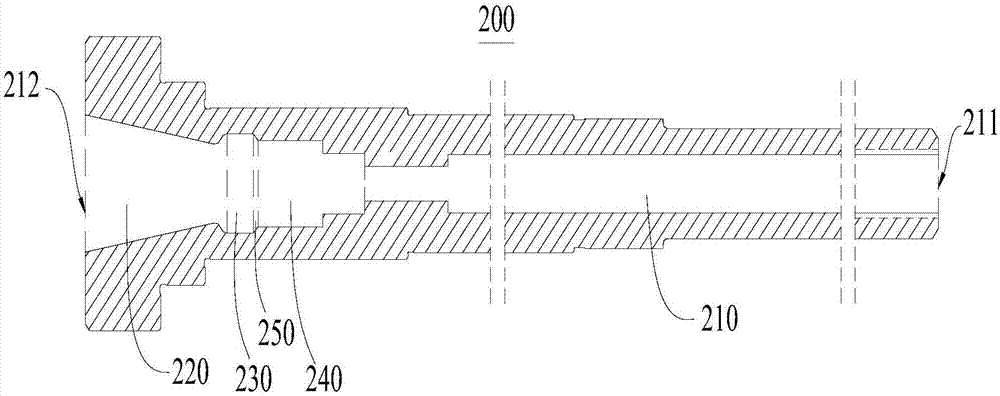

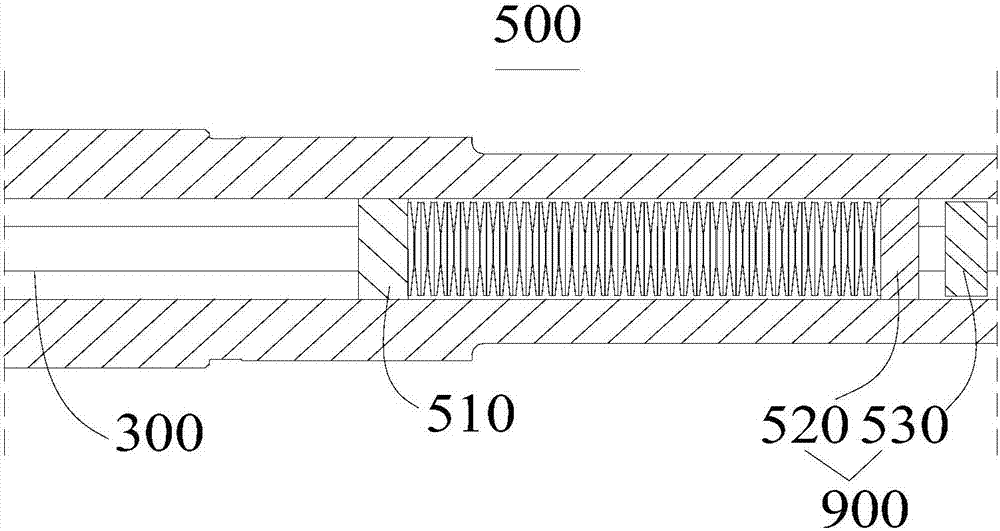

[0034] Please refer to figure 1 , the present embodiment provides a spindle broaching device 100 , which includes a spindle 200 , a push rod 300 , a claw 400 , and an elastic member 500 .

[0035] to combine figure 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com