A crane end beam transport workbench

A crane and workbench technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of easy slippage, unfavorable end beam guidance of different specifications, poor end beam guidance applicability, etc., and achieve good conveying effect. , Good applicability, easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

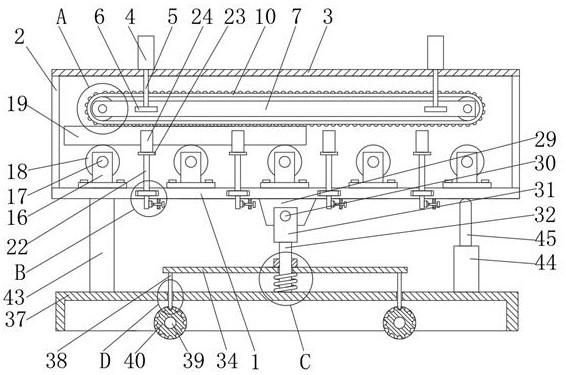

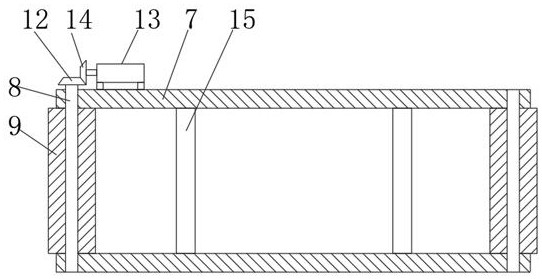

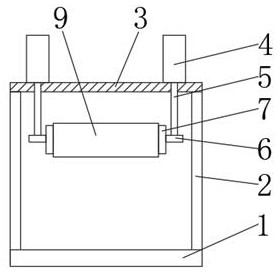

[0029] A crane end beam delivery workbench, comprising a support platform 1, four columns 2 are fixedly connected to the upper end of the support platform 1, and a support plate 3 is fixedly connected to the upper ends of the four columns 2, and the support plate 3 Four first cylinders 4 are fixedly installed on the upper end of the four first cylinders 4, and the first cylinder rods 5 of the four first cylinders 4 are slidably connected with the support plate 3, and the lower end of each first cylinder 4 is fixedly connected with a connecting seat 6 Each of the two connecting seats 6 is fixedly connected with a shaft frame 7, a connecting frame 15 is fixedly connected between the two shaft frames 7, and a roller shaft 8 is connected to the shaft frame 7 in rotation. The outer side of the shaft 8 is fixedly connected with a transmission roller 9, the transmission roller 9 is in contact with the axle frame 7, and the outer side of the transmission roller 9 is sleeved with a conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com