Hollow open lignin-based temperature-sensitive microsphere as well as preparation method and application thereof

A lignin-based and lignin-based technology, which is applied in the field of hollow open lignin-based thermosensitive microspheres and their preparation, can solve the problems of loss of functional substances, failure of intelligent control of cavities and openings, etc., and achieve the effect of loading and releasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

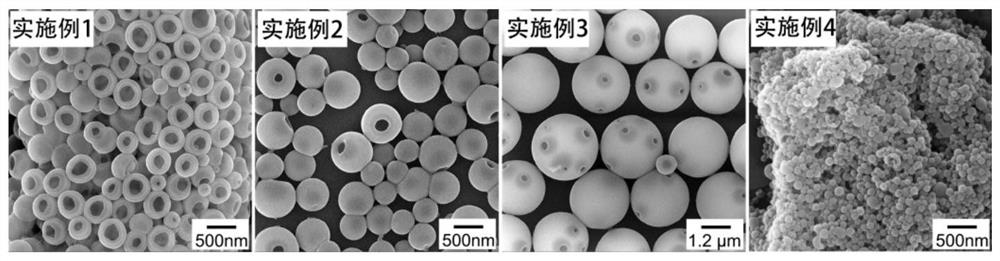

Embodiment 1

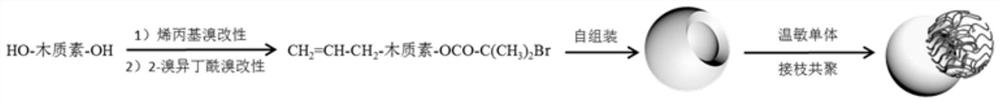

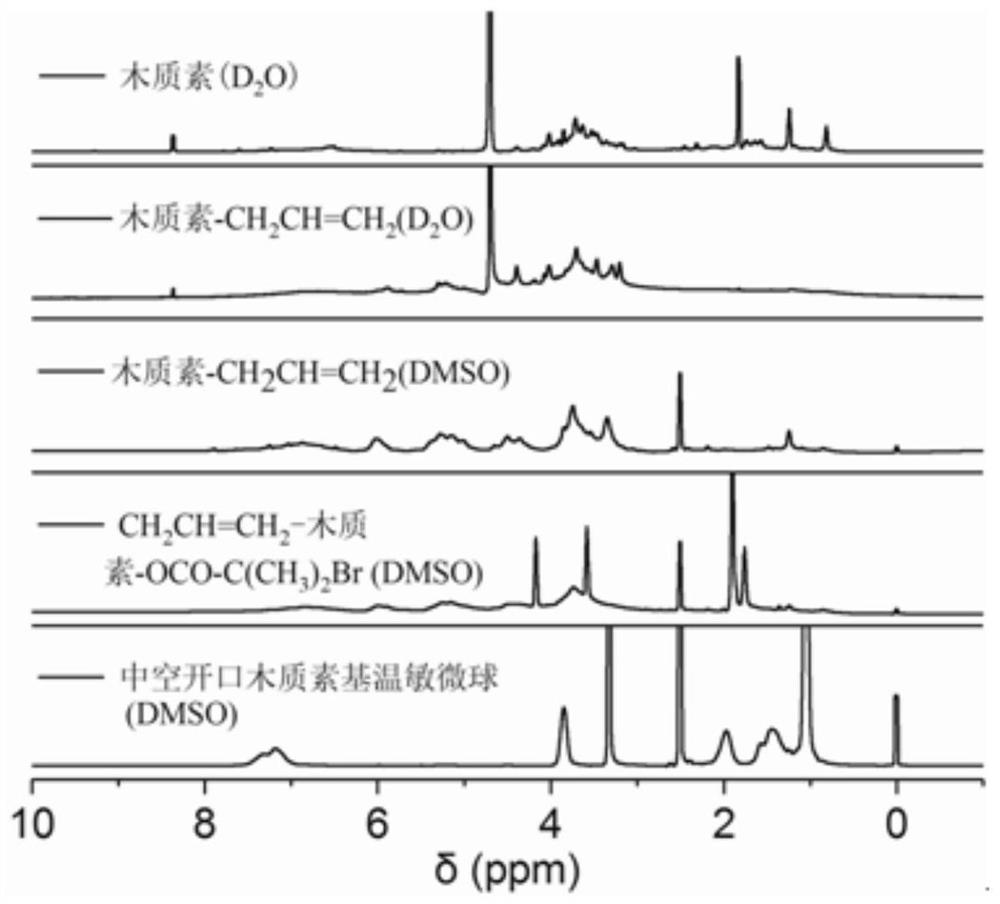

[0041] A hollow open lignin-based temperature-sensitive microsphere of the present invention is composed of a hollow open lignin microsphere and a temperature-sensitive polymer grafted onto the hollow open lignin microsphere, and the hollow open lignin-based temperature-sensitive microsphere has a bionic jellyfish structure , using the hollow open lignin microspheres as the jellyfish umbrella, and the thermosensitive polymer grafted on the hollow open lignin microspheres as the jellyfish tentacles.

[0042] In this embodiment, the hollow open lignin-based temperature-sensitive microspheres have temperature-sensitive properties and strong alkali shrinkage.

[0043] A method for preparing the hollow open lignin-based thermosensitive microspheres of the above embodiment, comprising the following steps:

[0044] S1: Dissolve 1g of lignin and 0.1g of sodium hydroxide in deionized water, slowly add 0.3g of allyl bromide, and stir at 40°C at a rate of 500rpm for 12h; after the reacti...

Embodiment 2

[0052] A hollow open lignin-based temperature-sensitive microsphere of the present invention is composed of a hollow open lignin microsphere and a temperature-sensitive polymer grafted onto the hollow open lignin microsphere, and the hollow open lignin-based temperature-sensitive microsphere has a bionic jellyfish structure , using the hollow open lignin microspheres as the jellyfish umbrella, and the thermosensitive polymer grafted on the hollow open lignin microspheres as the jellyfish tentacles.

[0053] In this embodiment, the hollow open lignin-based temperature-sensitive microspheres have temperature-sensitive properties and strong alkali shrinkage.

[0054] A method for preparing the hollow open lignin-based thermosensitive microspheres of the above embodiment, comprising the following steps:

[0055] S1: Dissolve 1g of lignin and 0.1g of sodium hydroxide in deionized water, slowly add 0.3g of allyl bromide, and stir at 40°C at a rate of 500rpm for 12h; after the reacti...

Embodiment 3

[0061] A hollow open lignin-based temperature-sensitive microsphere of the present invention is composed of a hollow open lignin microsphere and a temperature-sensitive polymer grafted onto the hollow open lignin microsphere, and the hollow open lignin-based temperature-sensitive microsphere has a bionic jellyfish structure , using the hollow open lignin microspheres as the jellyfish umbrella, and the thermosensitive polymer grafted on the hollow open lignin microspheres as the jellyfish tentacles.

[0062] In this embodiment, the hollow open lignin-based temperature-sensitive microspheres have temperature-sensitive properties and strong alkali shrinkage.

[0063] A method for preparing the hollow open lignin-based thermosensitive microspheres of the above embodiment, comprising the following steps:

[0064] S1: Dissolve 1g of lignin and 0.1g of sodium hydroxide in deionized water, slowly add 0.3g of allyl bromide, and stir at 40°C at a rate of 500rpm for 12h; after the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com