Material for three-dimensional modeling, combination of materials for three-dimensional modeling, method for manufacturing three-dimensional modeling object, and manufacturing device thereof

A technology of three-dimensional modeling and manufacturing methods, which is applied in the direction of liquid material additive processing, processing and manufacturing, and tool manufacturing. Excellent ejection stability, safe and easy to dissolve and remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] 400 g (2.16 mol) of 2-(diethylamino)ethyl methacrylate and 8.87 g (0.054 mol) of azobisisobutyronitrile were dissolved in 1.2 kg of methanol. Nitrogen gas was blown in for 60 minutes, exhausted, the container was covered with a septum, and polymerization was carried out at 60° C. for 20 hours. After the polymerization reaction, the solution was dried under reduced pressure, dissolved in 1 kg of dimethylformamide, added dropwise in diethyl ether, and the precipitate was recovered by suction filtration to obtain 2-(diethylamino)ethyl methacrylate. Polymer. The obtained 2-(diethylamino)ethyl methacrylate homopolymer had a weight average molecular weight of 120,000.

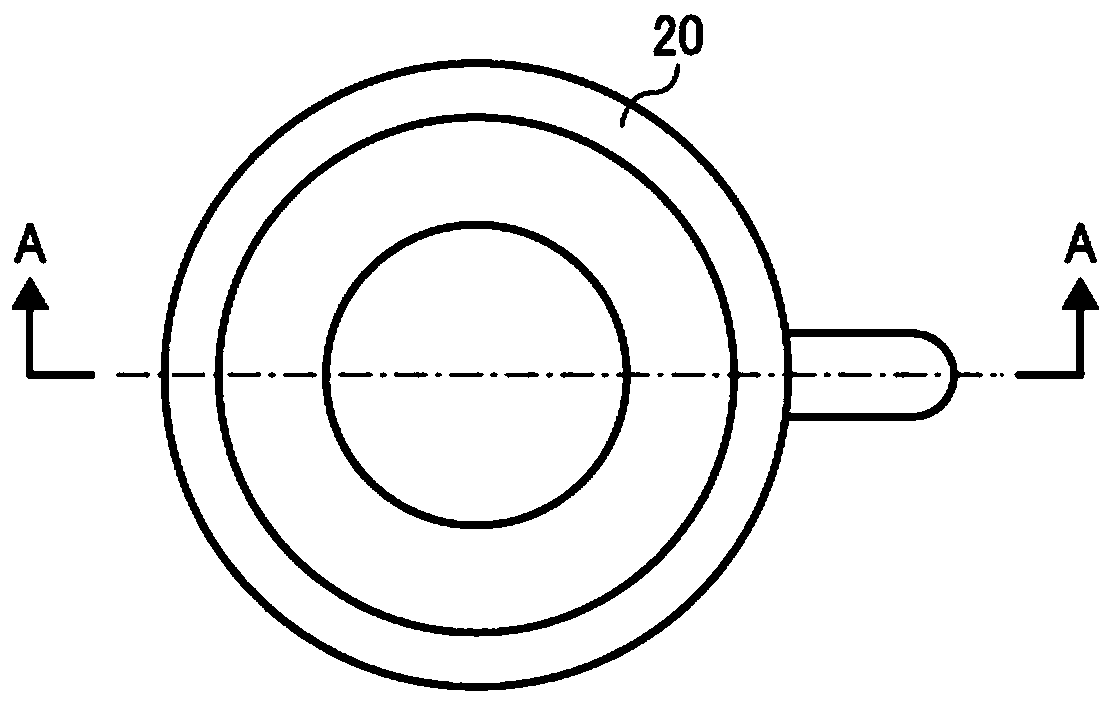

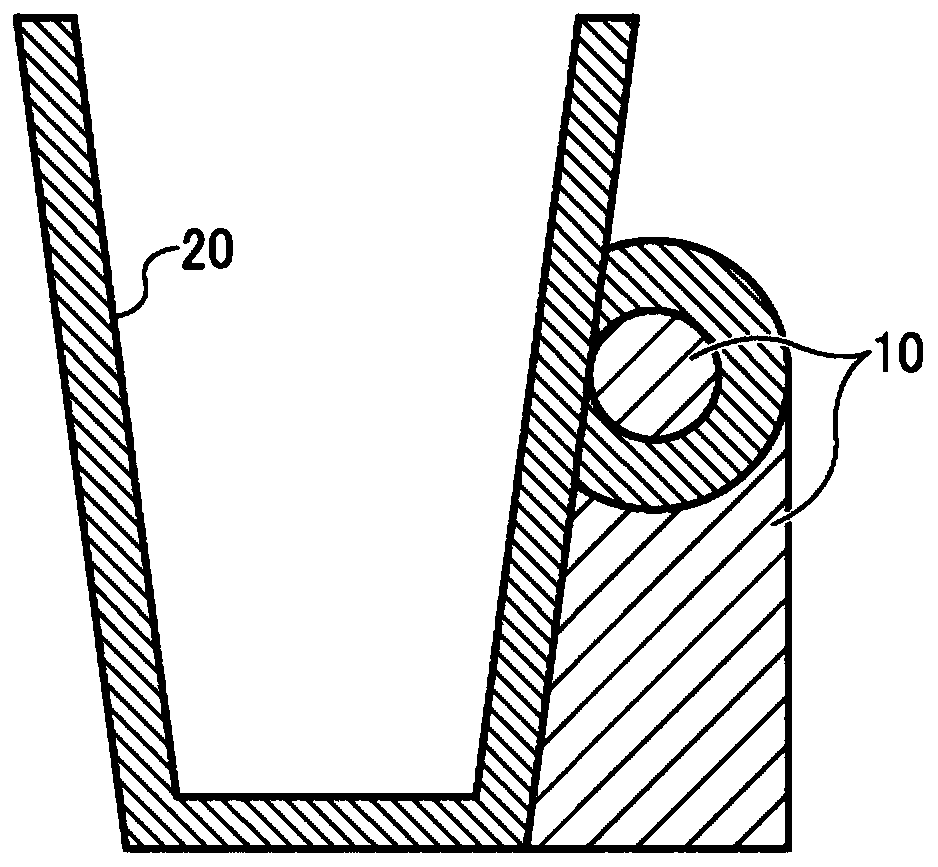

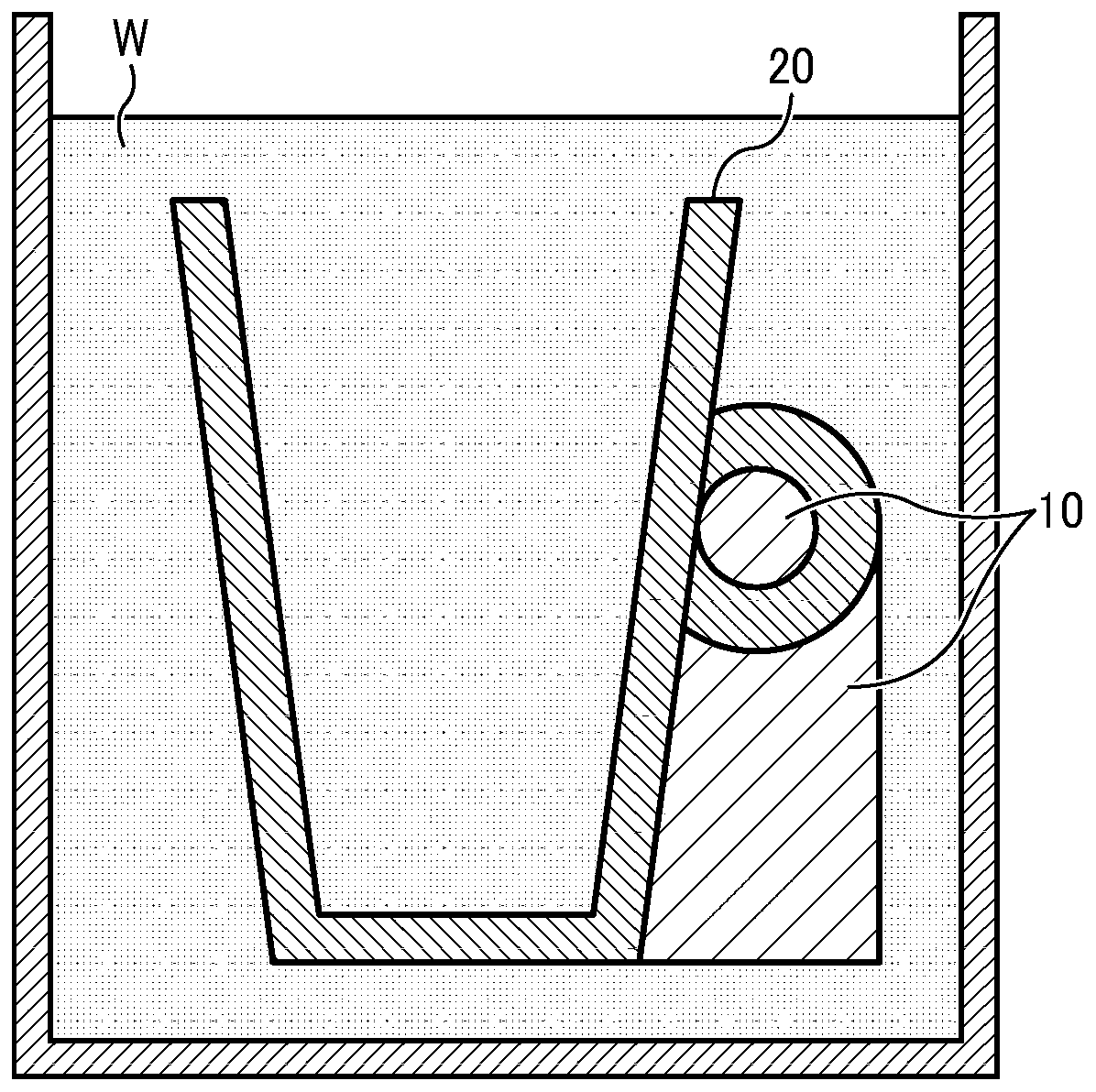

[0121] After drying the obtained homopolymer of 2-(diethylamino)ethyl methacrylate at 50° C. for 8 hours, use a 3D printer (Extruder Nozzle Pro made of 3D filament material, manufactured by Japan Binary Co., Ltd.), the melting temperature : 200° C., ejection speed: 0.5 m / min. A material for three-dimensional...

Embodiment 2

[0123] 400 g (3.63 mol) of 5-methacrylamide valerenic acid and 8.87 g (0.054 mol) of azobisisobutyronitrile were dissolved in 1.2 kg of methanol. Nitrogen gas was blown in for 60 minutes, exhausted, the container was covered with a septum, and polymerization was carried out at 60° C. for 20 hours. After the polymerization reaction, the solution was dried under reduced pressure, dissolved in 1 kg of dimethylformamide, added dropwise in diethyl ether, and the precipitate was recovered by suction filtration. The weight average molecular weight of the obtained 5-methacrylamide valerenic acid homopolymer was 120,000.

[0124] In Example 1, the methacrylic acid-2-(diethylamino)ethyl ester homopolymer was changed to 5-methacrylamide valerenic acid homopolymer, except that it was the same as in Example 1 to obtain a 1.75mm material for three-dimensional modeling.

Embodiment 3

[0126] 400 g (3.38 mol) of 6-methacrylamide caproic acid and 8.87 g (0.054 mol) of azobisisobutyronitrile were dissolved in 1.2 kg of methanol. Nitrogen gas was blown in for 60 minutes, exhausted, the container was covered with a septum, and polymerization was carried out at 60° C. for 20 hours. After the polymerization reaction, the solution was dried under reduced pressure, dissolved in 1 kg of dimethylformamide, added dropwise in diethyl ether, and the precipitate was recovered by suction filtration. The weight average molecular weight of the obtained 6-methacrylamide caproic acid homopolymer was 130,000.

[0127] In Example 1, the homopolymer of methacrylic acid-2-(diethylamino)ethyl ester was changed to 6-methacrylamide hexanoic acid homopolymer. 1.75mm material for three-dimensional modeling (filament for three-dimensional modeling).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com