A vehicle-mounted compensation type automatic lifting lift and its working method

A technology of automatic lifting and working methods, which is applied in the field of lifts, can solve the problems of increased work, difficulty, and difficulty of on-site maintenance of lifts, so as to improve stability and safety, reduce space and area, and save shipping fees Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

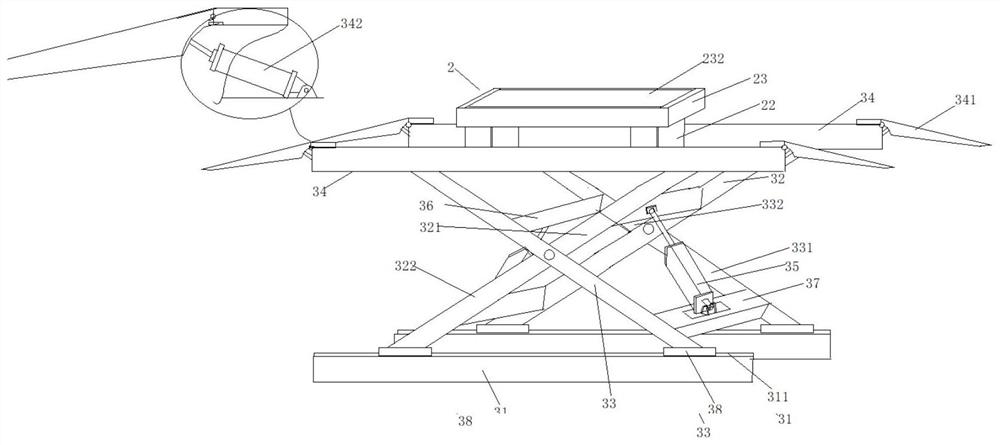

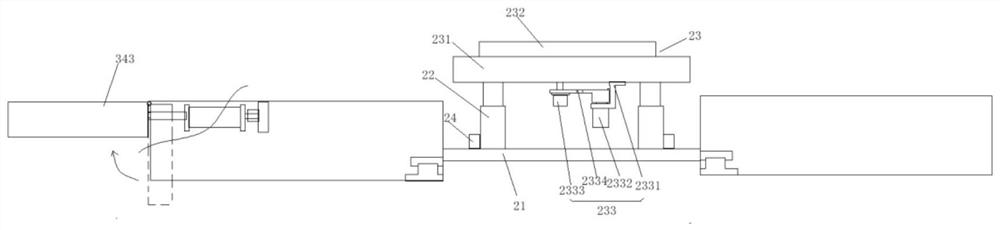

[0061] As shown in the figure, an angle-adjustable intelligent lift includes: a first-level lifting device 1 and a second-level lifting device 2, the first-level lifting device 1 includes a set of lifting mechanisms 3, and the The lifting mechanisms 3 are arranged opposite to each other, the secondary lifting device 2 is arranged between the two lifting mechanisms 3 , and the secondary lifting device 2 adopts a rotatable lifting device.

[0062] In this embodiment, the lift mechanism 3 includes a base 31 , a set of inner scissor arms 32 , a set of outer scissor arms 33 , a support platform 34 and a set of first lift drive mechanisms 35 , wherein the inner scissor arms 32 It includes an inner scissor arm 321 and an inner scissor lower arm 322. The outer scissor arm 33 includes an outer scissor upper arm 331 and an outer scissor lower arm 332. The inner scissor arm 32 crosses the outer scissor arm 33. Above the inner scissor arm 32 and the outer scissor arm 33, a drive arm 36 is...

Embodiment 2

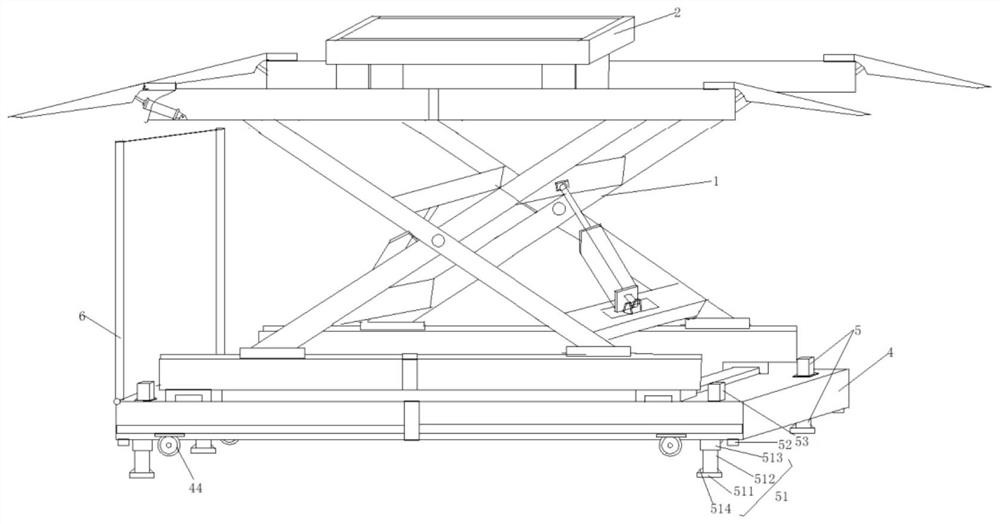

[0083] As shown in the figure, a vehicle-mounted compensating automatic lifting lift includes: a secondary lifting device, a telescopic frame 4, a compensation mechanism 5 and a boarding aid 6, wherein the secondary lifting device It includes a first-level lifting device 1 and a second-level lifting device 2. The first-level lifting device 1 includes a group of lifting mechanisms 3, and the lifting mechanism 3 is opposite to the telescopic frame 4. The stage lifting device 2 is arranged between the two lifting mechanisms 3, the compensating mechanism 5 is arranged at the lower part of the telescopic frame 4, the boarding aid 6 is arranged on one side of the telescopic frame 4, and the two Make flip connections.

[0084] In this embodiment, the lift mechanism 3 includes a base 31 , a set of inner scissor arms 32 , a set of outer scissor arms 33 , a support platform 34 and a set of first lift drive mechanisms 35 , wherein the inner scissor arms 32 It includes an inner scissor a...

Embodiment 3

[0099] As shown in the figure, a vehicle-mounted compensating automatic lifting lift includes: a secondary lifting device, a telescopic frame 4, a compensation mechanism 5 and a boarding aid 6, wherein the secondary lifting device It includes a first-level lifting device 1 and a second-level lifting device 2. The first-level lifting device 1 includes a group of lifting mechanisms 3, and the lifting mechanism 3 is opposite to the telescopic frame 4. The stage lifting device 2 is arranged between the two lifting mechanisms 3, the compensating mechanism 5 is arranged at the lower part of the telescopic frame 4, the boarding aid 6 is arranged on one side of the telescopic frame 4, and the two Make flip connections.

[0100] In this embodiment, the lift mechanism 3 includes a base 31 , a set of inner scissor arms 32 , a set of outer scissor arms 33 , a support platform 34 and a set of first lift drive mechanisms 35 , wherein the inner scissor arms 32 It includes an inner scissor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com