Method for preparing starch ionomer and its modified fully degradable plastic

An ionomer, full-degradation technology, applied in the production of bulk chemicals, etc., can solve the problems of polyester blends such as the decline in mechanical properties, difficult to exceed the amount of addition, poor thermal stability, etc., to improve processing performance and increase processing viscosity , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

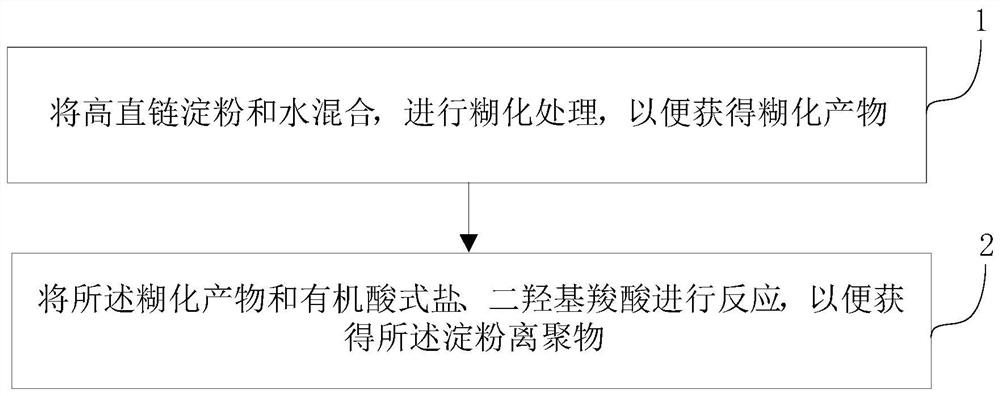

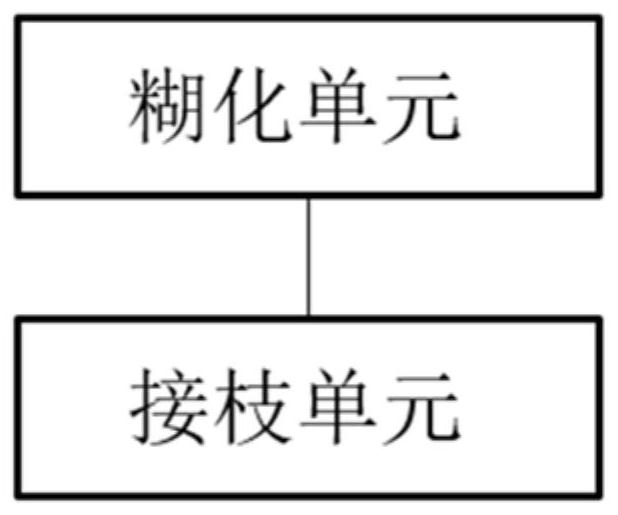

[0062] 1) Mix high amylose starch and water in a ratio of 1:0.1, and gelatinize at 80°C for 80min. The gelatinized high amylose starch, monosodium citrate, and dimethylol propionic acid were added to the supercritical carbon dioxide reaction kettle in a ratio of 1:0.3:0.8, and in a supercritical carbon dioxide fluid at 40 ° C and 12 MPa, in a fluidized bed. The reaction is carried out in the form of a reaction product, and the reaction product leaves the reactor with the carbon dioxide fluid, and is separated under reduced pressure to obtain a starch ionomer.

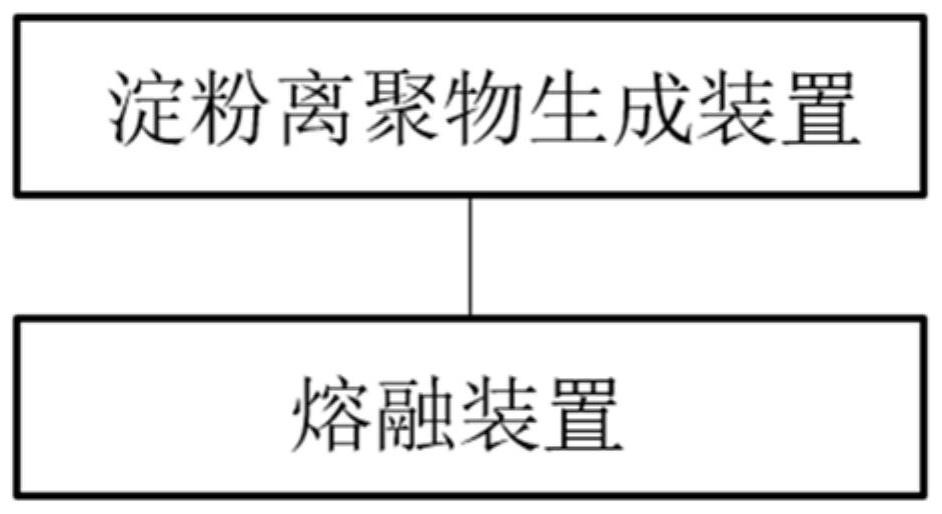

[0063] 2) Mix the synthesized starch ionomer and PLA at a ratio of 1:0.25, melt extrusion and granulation through twin-screw, and the extrusion temperature is 180°C to obtain a fully degradable plastic.

Embodiment 2

[0065] 1) Mix high amylose starch with water in a ratio of 1:0.2, and gelatinize at 90°C for 40min. The gelatinized high amylose starch, monosodium fumarate, and dimethylol propionic acid were added to the supercritical carbon dioxide reaction kettle in the ratio of 1:0.5:0.4, and the fluidized bed was carried out in the supercritical carbon dioxide fluid at 40 ° C and 10 MPa. The reaction is carried out in the form of carbon dioxide fluid, and the reaction product leaves the reactor with carbon dioxide fluid, and is separated under reduced pressure to obtain a starch ionomer.

[0066] 2) Mix the synthesized starch ionomer and PBAT at a ratio of 1:0.5, melt extrusion and granulation through twin-screw, and the extrusion temperature is 110°C to obtain a fully degradable plastic.

Embodiment 3

[0068] 1) Mix high amylose starch with water in a ratio of 1:0.5, and gelatinize at 100°C for 30min. The gelatinized high amylose starch, monosodium malate, and dimethylolbutyric acid were added to the supercritical carbon dioxide reaction kettle in the ratio of 1:0.8:0.3, and in a supercritical carbon dioxide fluid at 40 ° C and 8 MPa, in a fluidized bed. The reaction is carried out in the form of a reaction product, and the reaction product leaves the reactor with the carbon dioxide fluid, and is separated under reduced pressure to obtain a starch ionomer.

[0069] 2) Mixing the synthesized starch ionomer and PBS in a ratio of 1:3, and granulating by twin-screw melt extrusion, and the extrusion temperature is 150° C. to obtain a fully degradable plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com