High hardness thermoplastic polyurethane elastomer and preparation method thereof

A technology of thermoplastic polyurethane and high hardness, which is applied in the field of thermoplastic polyurethane elastomer and its preparation, and can solve problems such as difficulty in realizing the shape recovery function of thermoplastic materials, insufficient phase separation of soft and hard segments, and reduction of crosslinking structure between molecular chains. Achieve excellent processability, improve heat resistance and lower melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation of the embodiments of the present invention all adopts the same preparation steps, specifically including the following steps:

[0060] (1) Heat the polyol (a) to 150°C, and when it is completely melted, add the polyol (b) and stir well to form component A;

[0061] Among them, if a catalyst or additive is added, it is added in step (1) and blended with component A;

[0062] (2) Heat the diisocyanate to 50°C and form component B after melting completely;

[0063] (3) Heat the diol to 50°C to form component C;

[0064] (4) Mix components A, B and C and add them to the front of the extruder for polymerization reaction. The reaction temperature is 210°C. When components A, B and C start to react, Then add monohydric alcohol in the middle section to continue the reaction, the above-mentioned reaction time is 5 min, and finally cool down to below the thermoplastic polyurethane melting point temperature to obtain a high-hardness thermoplastic polyurethane el...

Embodiment 1

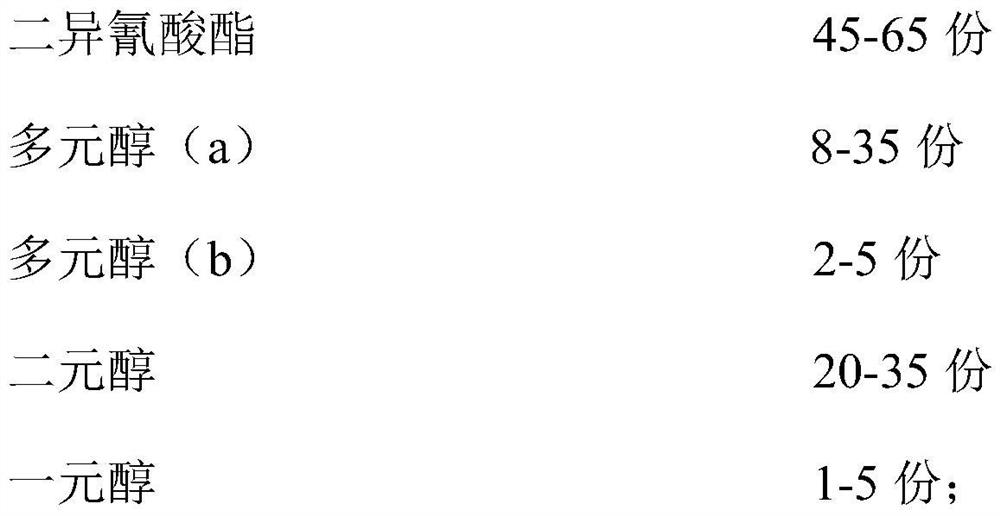

[0071] Weigh the following raw materials in parts by weight:

[0072] 57.6 parts of diisocyanate

[0073] Polyol (a) 15.1 parts

[0074] Polyol (b) 3 parts

[0075] 26.3 parts of dihydric alcohol

[0076] Monohydric alcohol 2 parts

[0077] in:

[0078] Diisocyanate is diphenylmethane diisocyanate, polyol (a) is polybutylene adipate with a number average molecular weight of 2000 g / mol, polyol (b) is trimethylolpropane, diol It is 1,6-hexanediol, and the monohydric alcohol is 1-stearyl alcohol;

Embodiment 2

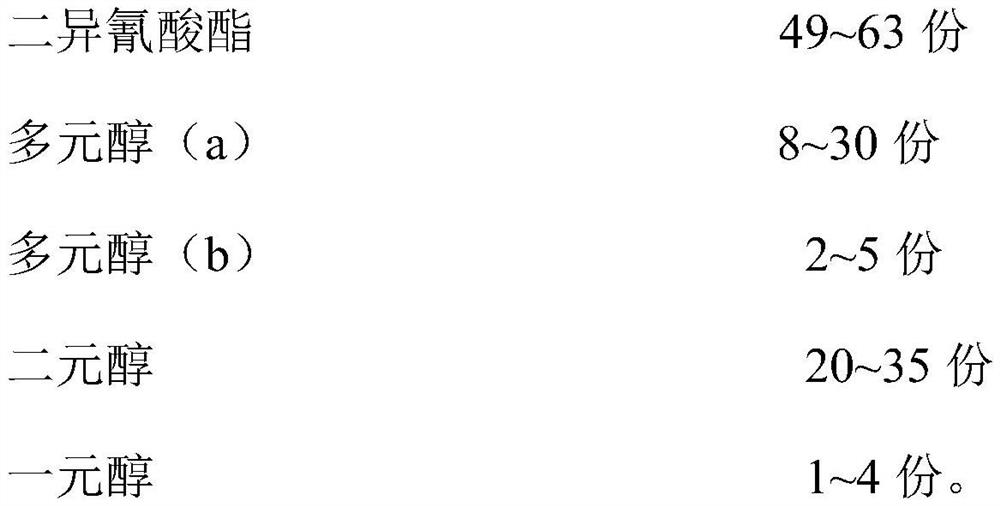

[0080] Weigh the following raw materials in parts by weight:

[0081] 49.5 parts of diisocyanate

[0082] Polyol (a) 27.7 parts

[0083] Polyol (b) 5 parts

[0084] 21.7 parts of dihydric alcohol

[0085] Monohydric alcohol 4 parts

[0086] in:

[0087] Diisocyanate is diphenylmethane diisocyanate, polyol (a) is polybutylene adipate with a number average molecular weight of 2000 g / mol, polyol (b) is trimethylolpropane, diol It is 1,6-hexanediol, and the monohydric alcohol is 1-stearyl alcohol;

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com