Voltage division proportion adjusting circuit, switch control circuit and cooking utensil

A switch control circuit, proportional adjustment technology, applied in induction heating control, household appliances, electric heating fuel, etc., can solve the problem that the synchronous circuit is difficult to meet the requirements of work and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

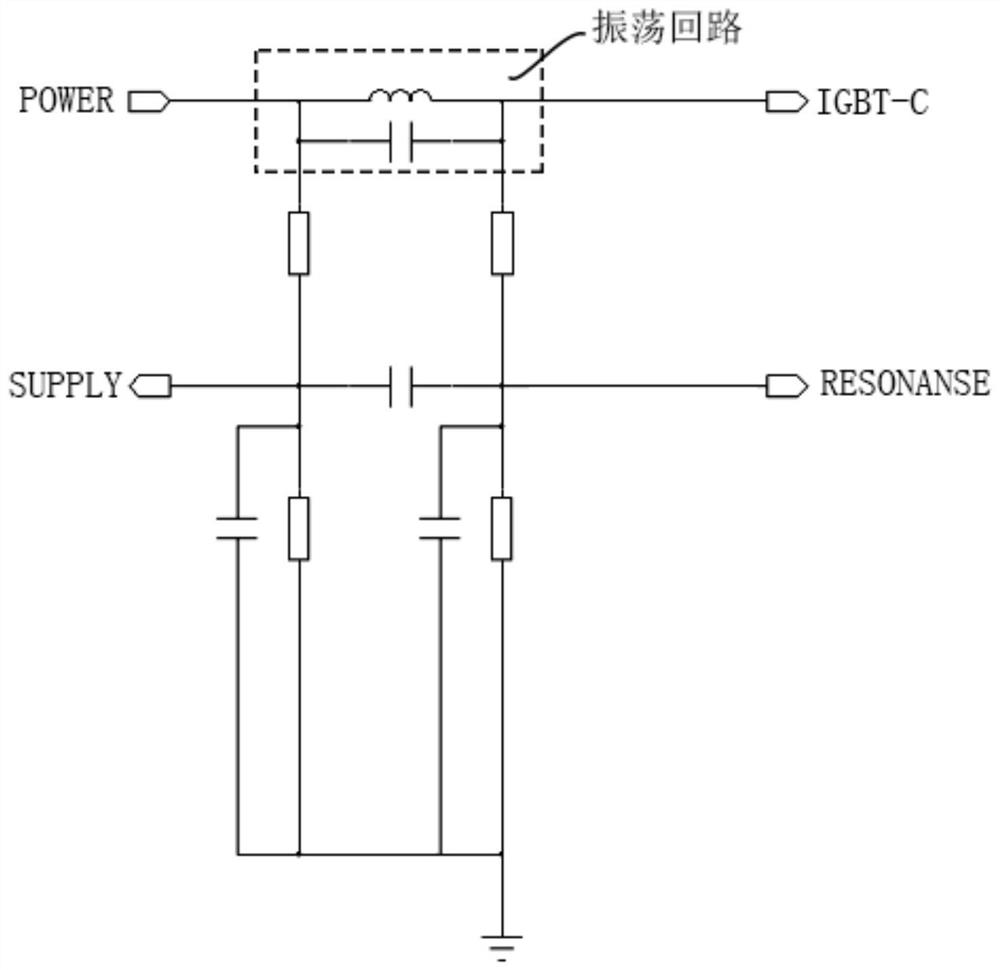

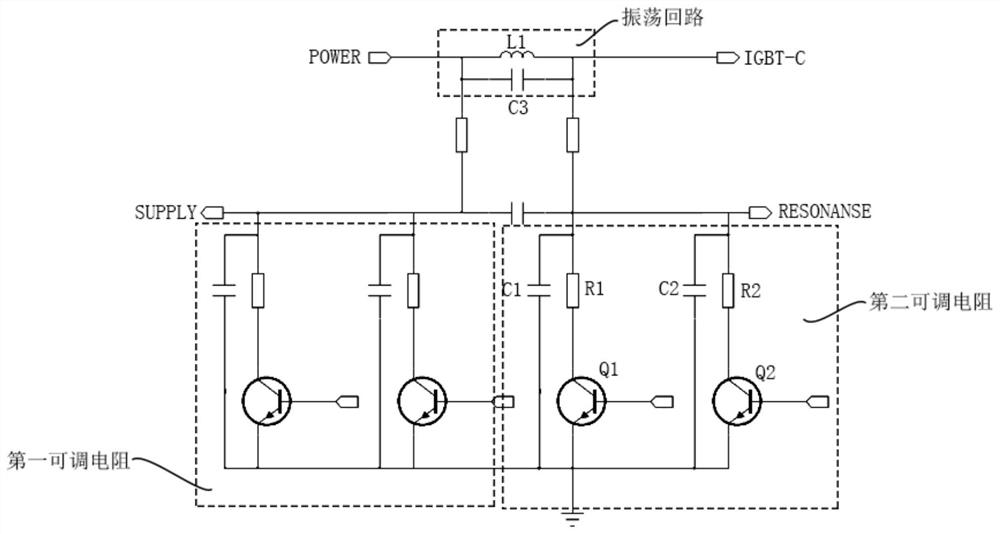

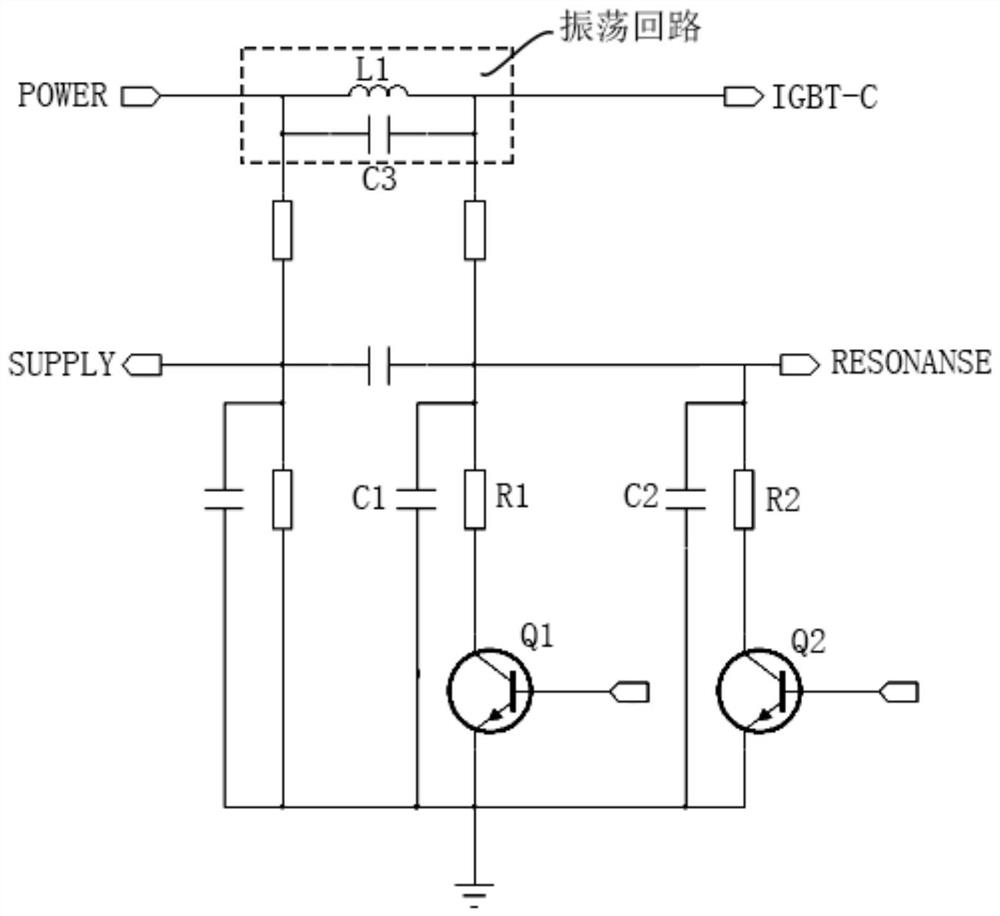

[0041] Such as figure 2 As shown, the embodiment of the present invention provides a voltage division ratio adjustment circuit, the voltage division ratio adjustment circuit includes: an oscillation circuit, a first voltage detection terminal SUPPLY, a second voltage detection terminal RESONANCE, a first adjustable resistance and a second Adjustable resistance.

[0042] The first end of the oscillating circuit is used to connect to the power supply, and the second end of the oscillating circuit is used to connect to the resonance end of the IGBT module. The first voltage detection terminal SUPPLY is connected to the first end of the oscillation circuit through the first resistor R3, and the first voltage detection terminal SUPPLY is used to detect the voltage shared by the first adjustable resistor. The second voltage detecting terminal RESONANCE is connected to the second terminal of the oscillation circuit through the second resistor R4, and the second voltage detecting te...

Embodiment 2

[0053] Such as Figure 4 As shown, the embodiment of the present invention also provides a switch control circuit, which includes a control module, an IGBT module, and the voltage division ratio adjustment circuit described in the above-mentioned embodiments.

[0054] The first input terminal of the control module is connected to the first voltage detection terminal SUPPLY, the second input terminal of the control module is connected to the second voltage detection terminal RESONANCE, and the first output terminal of the control module is connected to the The control terminal of the IGBT module is connected, and the control module is also provided with a plurality of second output terminals, and the control module sends control to the switch modules of the multiple resistance modules in the voltage division ratio adjustment circuit through the second output terminals. Signal; the other end of the IGBT module is grounded, that is, the E pole of the IGBT module is grounded.

[...

Embodiment 3

[0064] An embodiment of the present invention also provides a cooking appliance, which includes: the voltage division ratio adjustment circuit described in any one of the above embodiments, and / or the switch control circuit described in any one of the above embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com