Double-Z-axis separate-taking simultaneous-mounting belt corner efficient mounting head

A placement head, Z-axis technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of reducing production efficiency, achieve the effect of improving placement efficiency, reducing the number of transportation, and reducing placement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

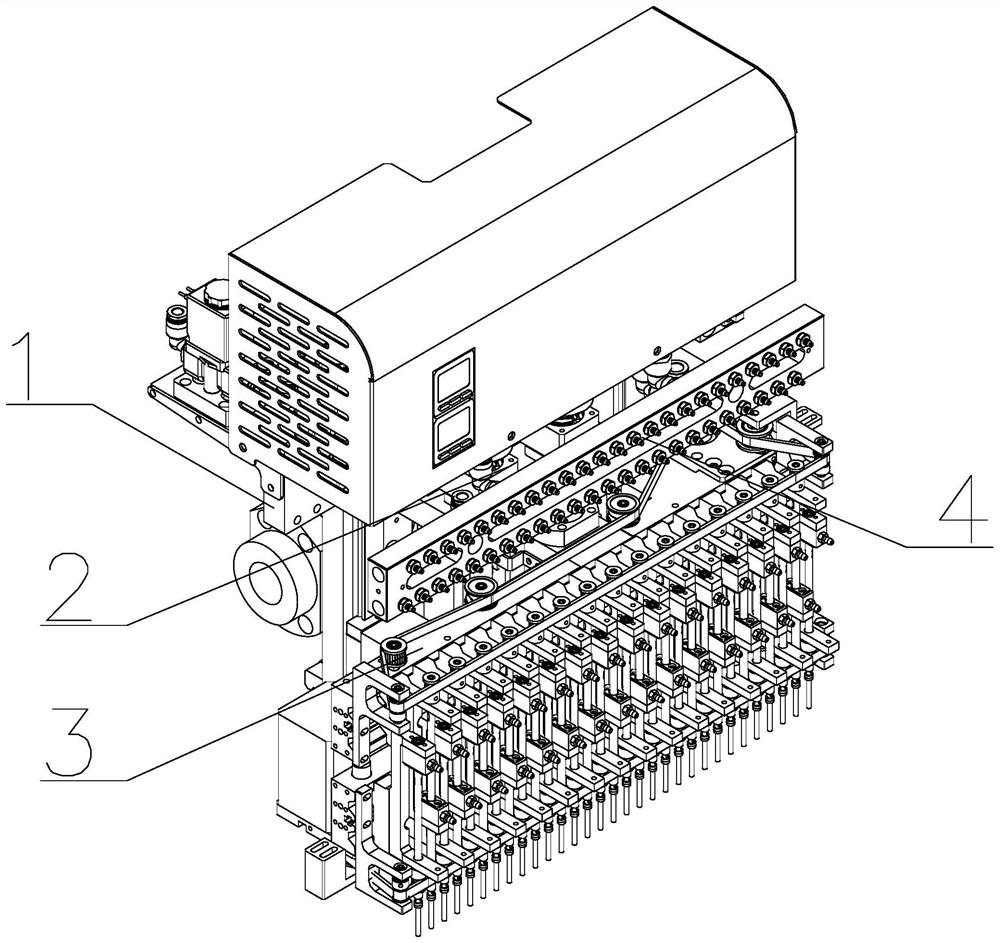

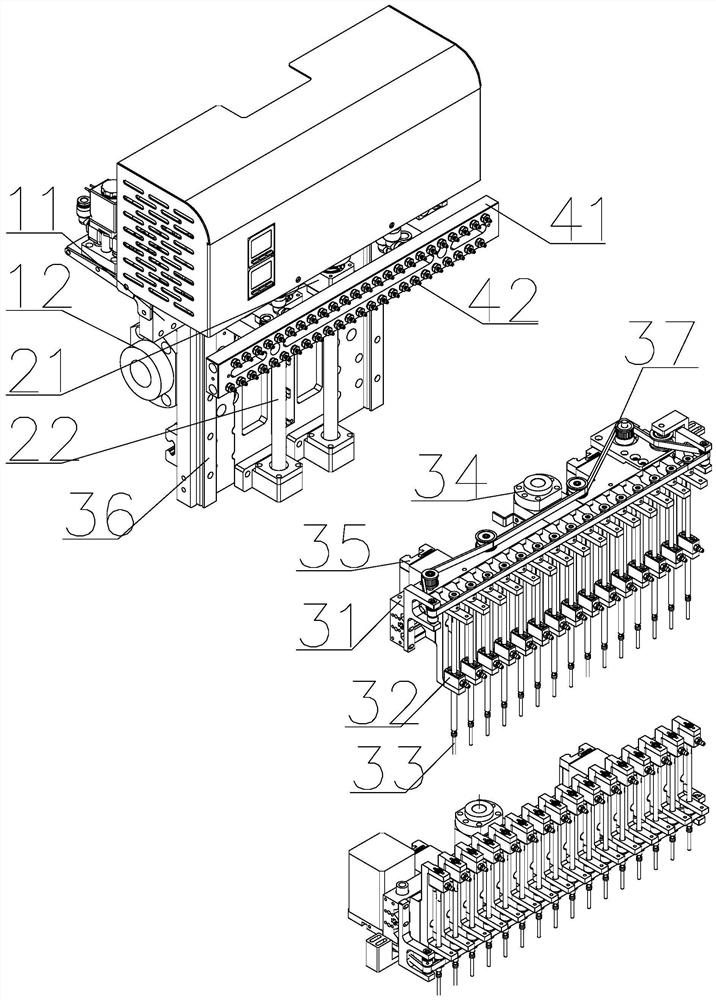

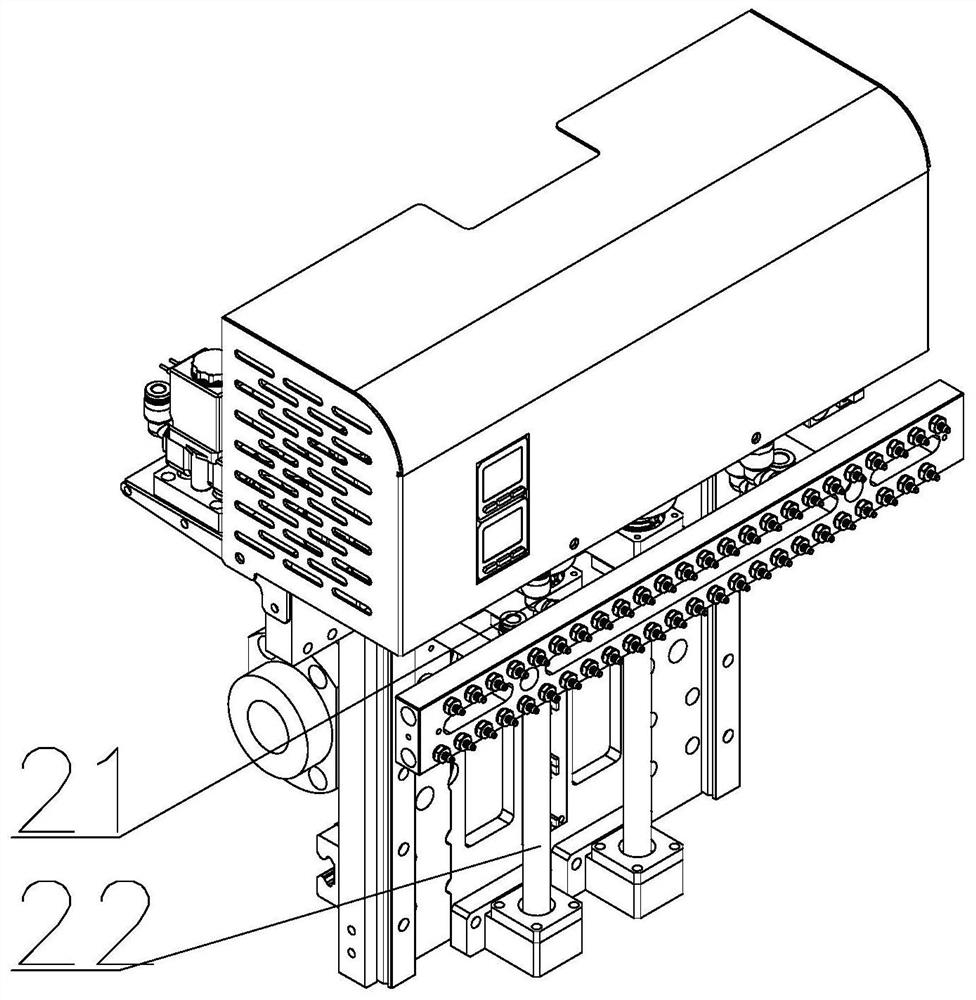

[0019]Seefigure 1 ,figure 2 ,image 3 withFigure 4A dual z-axis, divided into the same post, a belt corner, high-efficiency head, including a patch machine sticker, a material lifting power mechanism 2, a gas suction transfer mechanism 3, and a pressure control mechanism 4, The patch machine sticker is firmly provided with two groups of material rising power mechanism 2, which is provided with a gas suction material transfer mechanism 3, two of the air suction method, respectively. The gas suction material transfer mechanism 3 is arranged up and down, and the pressure control mechanism 4 is connected to the air suction metal transfer mechanism 3.

[0020]The patch machine sticker is provided with a gas pressure control mechanism 4 for controlling the air pressure of the gas suction material transfer mechanism 3. The air pressure control mechanism 4 controls the air pressure of the gas suction material transfer mechanism 3, which can make gas suction The material transfer mechanism 3 ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com