Lubricating oil filtering and collecting method

A lubricating oil and filter box technology, which is applied in the field of lubricating oil filtration, can solve the problems of poor filtering and purification effect of lubricating oil, affecting the fluidity of oil pipelines, and difficulty in disassembly and maintenance, so as to improve the magnetic adsorption effect and ensure the quality of oil products , the effect of reducing the content of slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

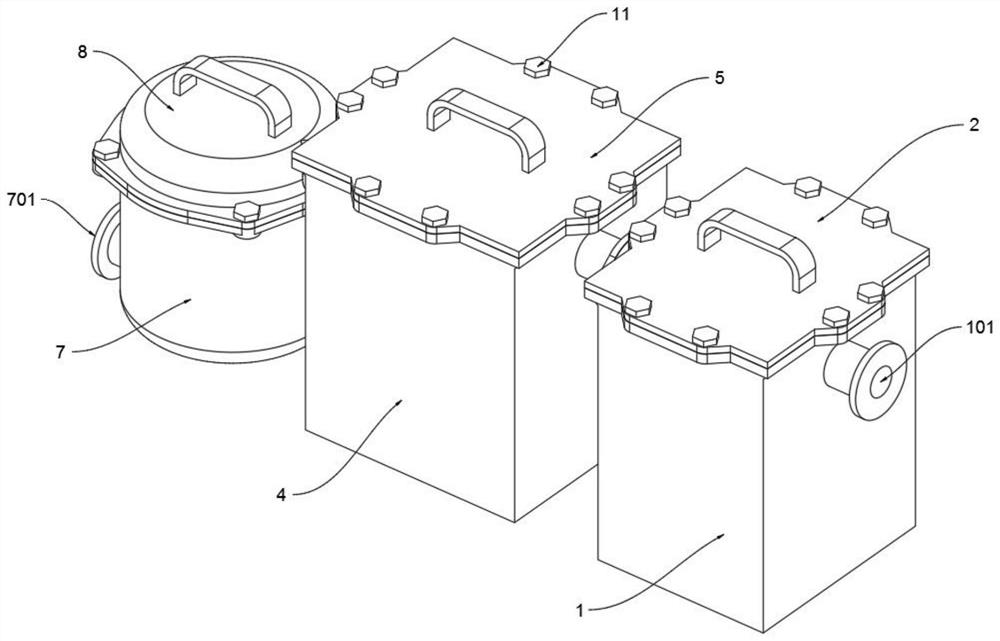

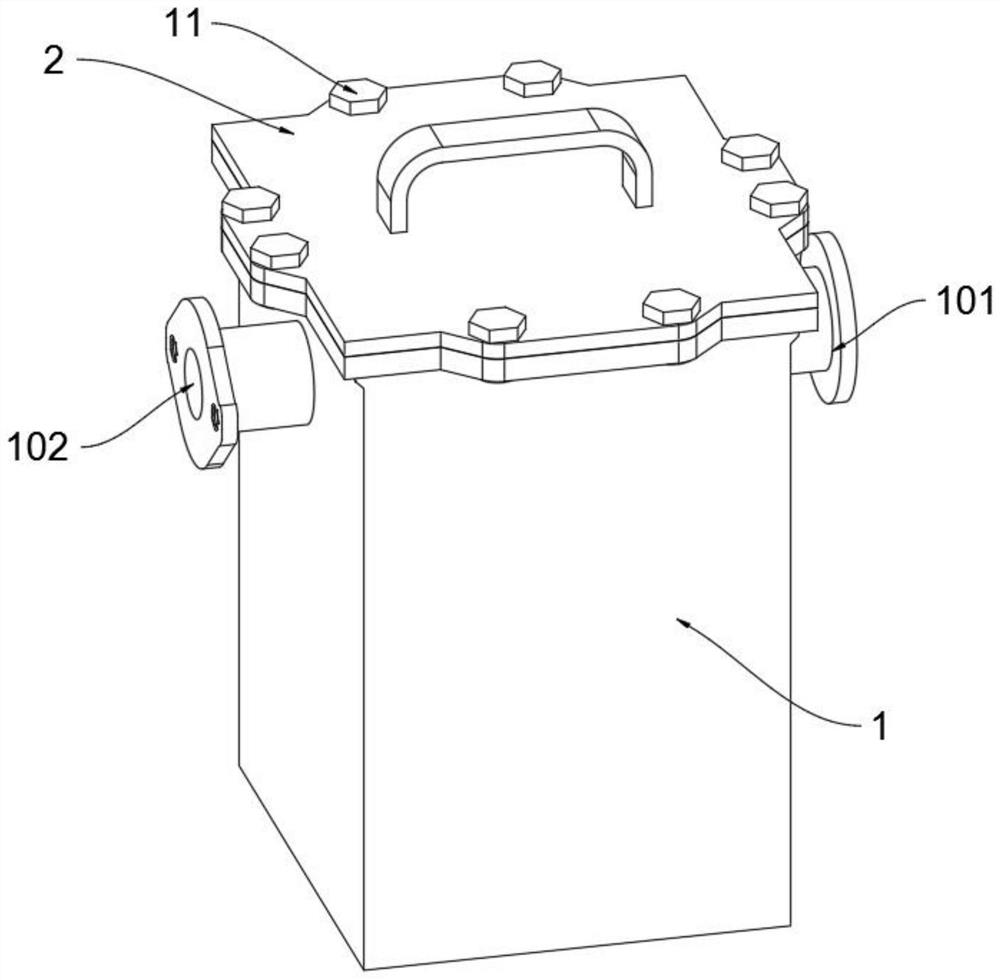

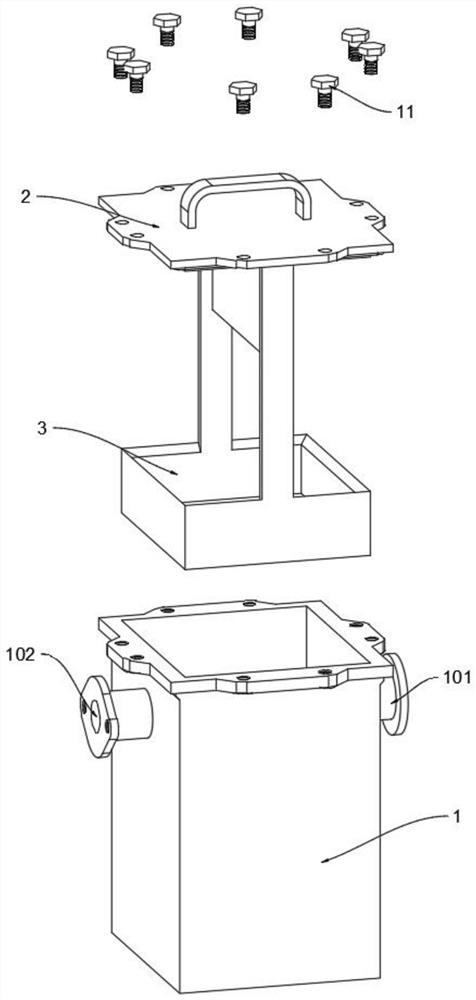

[0027] as attached figure 1 to attach Figure 8 Shown:

[0028] The invention provides a method for filtering and collecting lubricating oil. The method for filtering and collecting lubricating oil is completed by filtering and collecting equipment for lubricating oil, thereby realizing the filtering and collecting of lubricating oil; the filtering and collecting equipment for lubricating oil includes sedimentation Box 1, adsorption box 4, filter box 7 and filter frame 9; the left and right ends of the top of the sedimentation box 1 are respectively provided with an oil inlet pipe port A101 and an oil outlet pipe port A102, and the sedimentation box 1 is a hollow structure, and the sedimentation sealing cover 2 is buckled on the top of the sedimentation tank 1; the left and right ends of the top of the adsorption tank 4 are respectively provided with an oil inlet pipe port B402 and an oil outlet pipe port B403, and the adsorption tank 4 is a hollow structure, and the adsorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com