Multi-lane automatic unloading control device and control method for large crusher

A control device and automatic unloading technology, applied in transportation and packaging, loading/unloading, grain handling, etc., can solve the problems of shortening the service life of conveyor belts, high manual work intensity, affecting safe and civilized production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

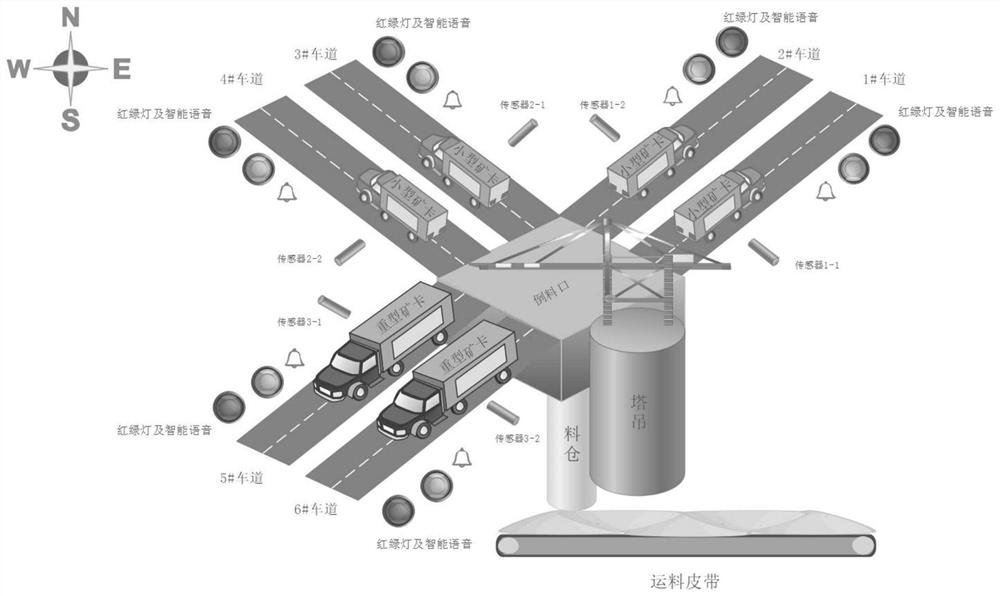

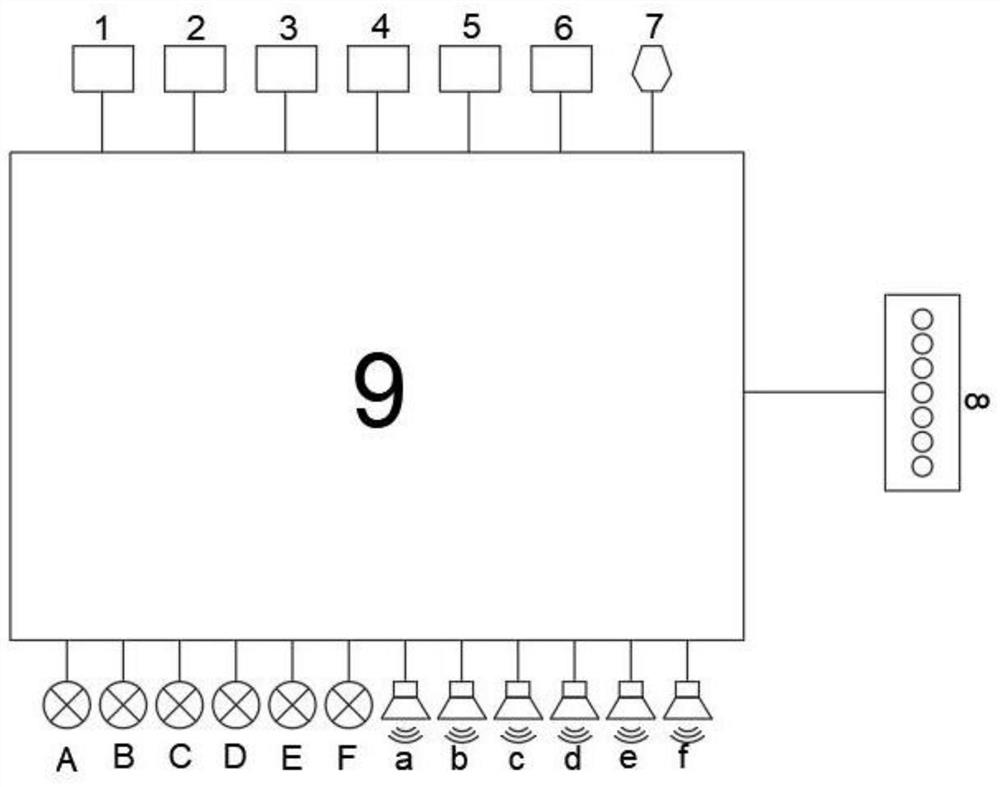

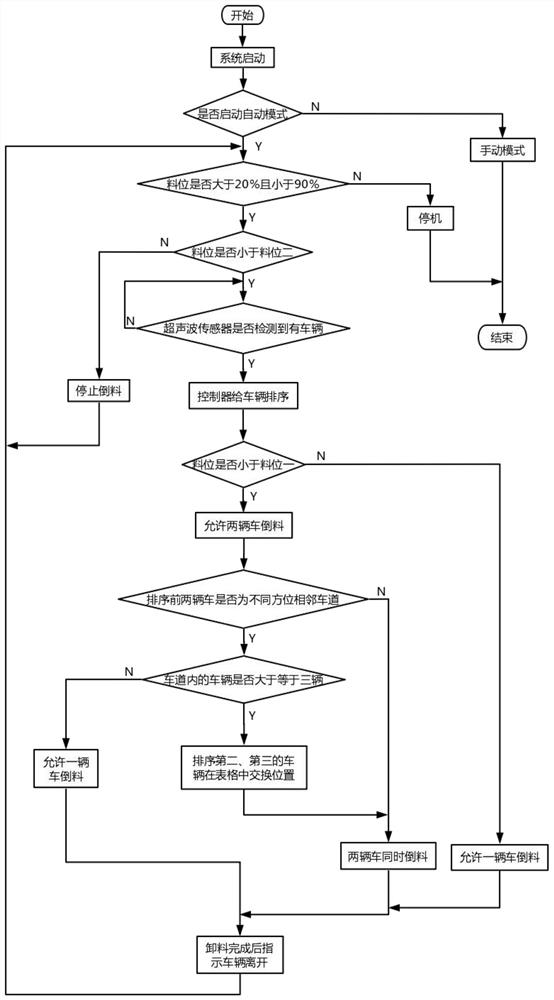

[0037] Such as Figure 1 to Figure 3 As shown, the multi-lane automatic unloading control device for a large crusher described in this embodiment, the control device includes a crusher, a controller, a detector, a prompt module, and a conveying device. There is a discharge port above the crusher, and a discharge port below. There are several lanes connected to the discharge port at the discharge port, and the discharge port is connected to the conveying device. The discharge opening is in the shape of a cuboid, with three sides as the discharge surface and the other side as the blocking surface. Each discharge surface is provided with two parallel lanes, and the two parallel lanes are vertically connected to the discharge opening. The large The device has a total of six lanes, which are numbered sequentially, such as Figure 1As shown, #1, #2, #3, #4, #5, #6 are lane numbers. A tower crane is installed on the outside of the other blocking surface. The tower crane is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com