Lead-zinc ore dressing pulp heating device

A technology of ore slurry and lead-zinc, which is applied in the direction of solid separation, etc., can solve the problems that the heat source cannot be recycled, the leakage point accident is harmful, and the ambient temperature of the heating site is high, so as to achieve a simple structure, a friendly site environment, and less heat loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

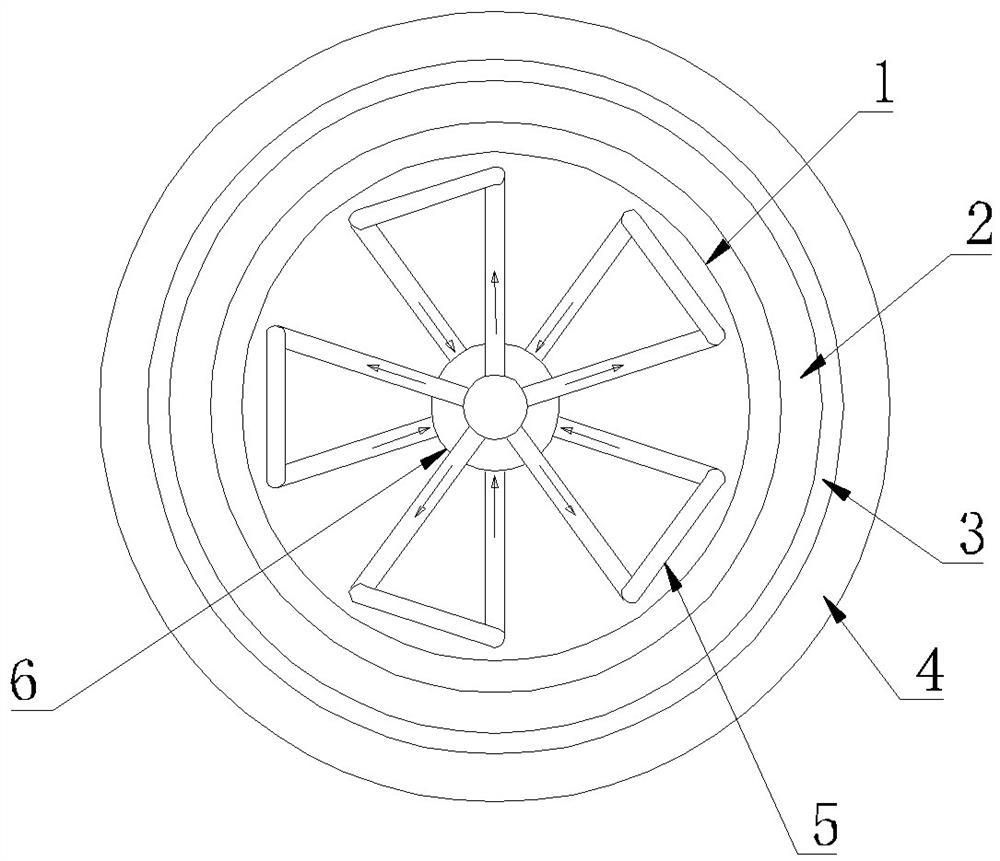

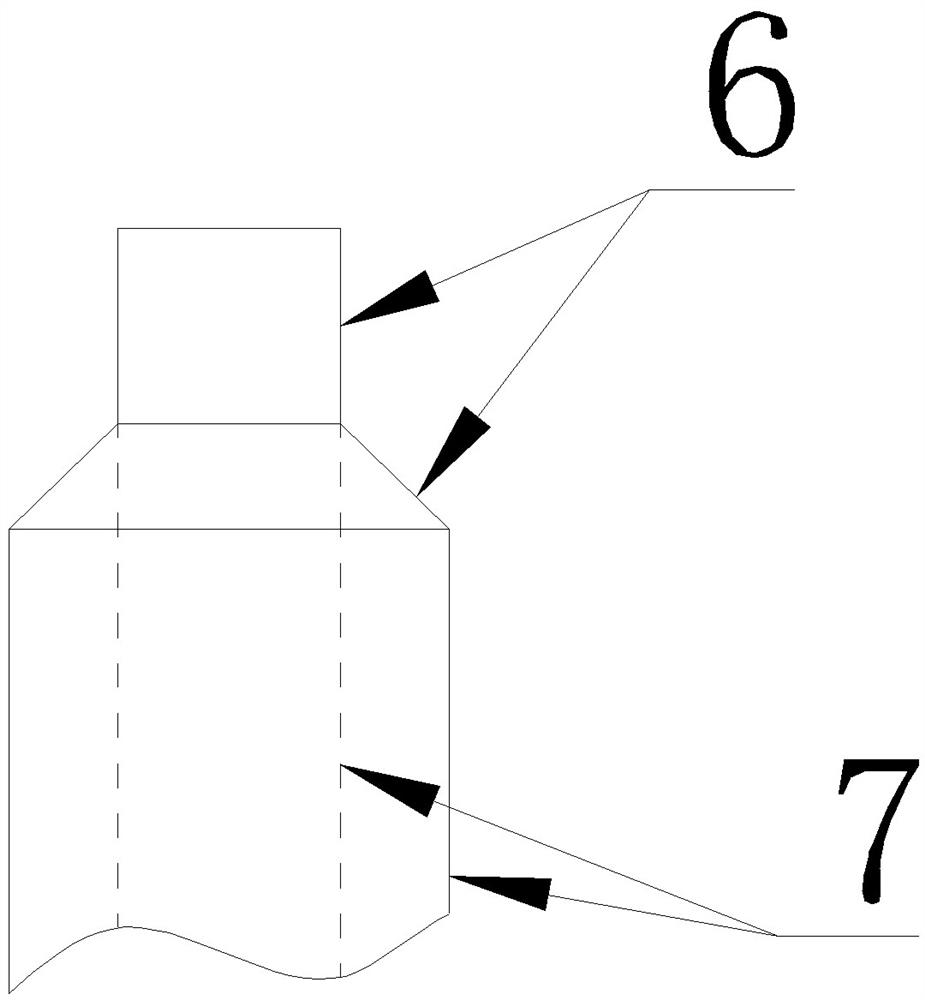

[0017] Such as Figure 1-2 A kind of lead-zinc ore dressing slurry heating device shown includes a slurry inner wall 1, and the bottom of the slurry inner wall 1 is provided with a pipeline joint 6, and the pipeline joint 6 is connected to a double chamber pipeline 7, and the described At least two sets of output and input ports are provided on the pipe joint 6, and the output port and the input port are communicated through the thermal pipeline 5, the thermal pipeline 5 is a one-way return pipeline, and the thermal pipeline 5 is along the slurry The bottom surface of the inner wall 1 is radially arranged, and the thermal pipeline 5 is vertically arranged along the inner wall of the slurry inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com