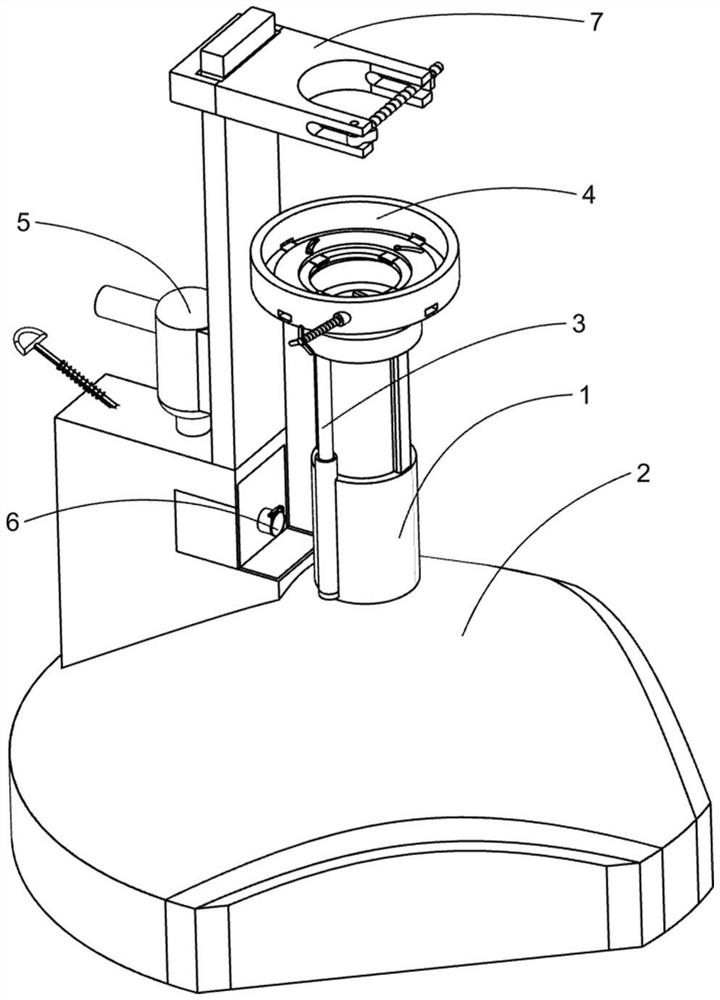

A convenient detachable electric hammer vacuuming device

A dust collection device and a technology that is easy to disassemble. It is applied in the direction of portable impact tools, metal processing equipment, maintenance and safety accessories, etc. It can solve the problems that the electric hammer cannot be disassembled and cannot meet the dust collection needs of different electric hammers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

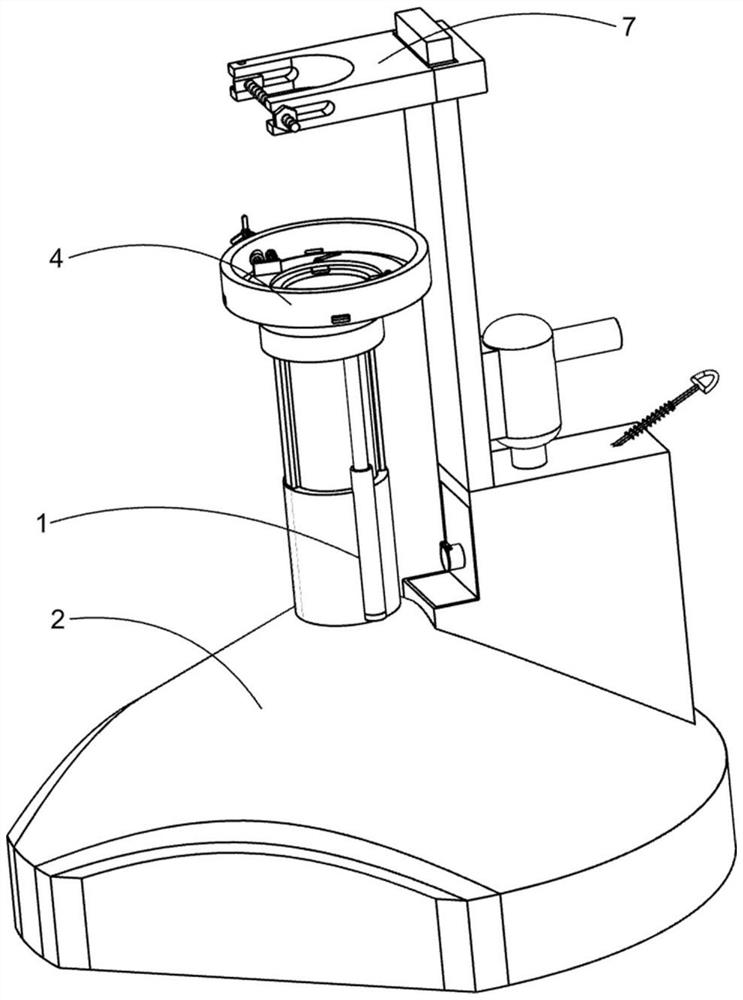

[0031] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS: When a worker uses the device, he first rotates the locking screw 703 to keep the locking nut 704 away from the U-shaped plate 701, then places the electric hammer on the U-shaped plate 701, and then rotates the locking screw 703 to make the locking nut 704 away from the U-shaped plate 701. 704 is in contact with the U-shaped plate 701 to limit the swing of the locking screw 703, and the main body of the electric hammer is fixedly installed on the device through the locking screw 703.

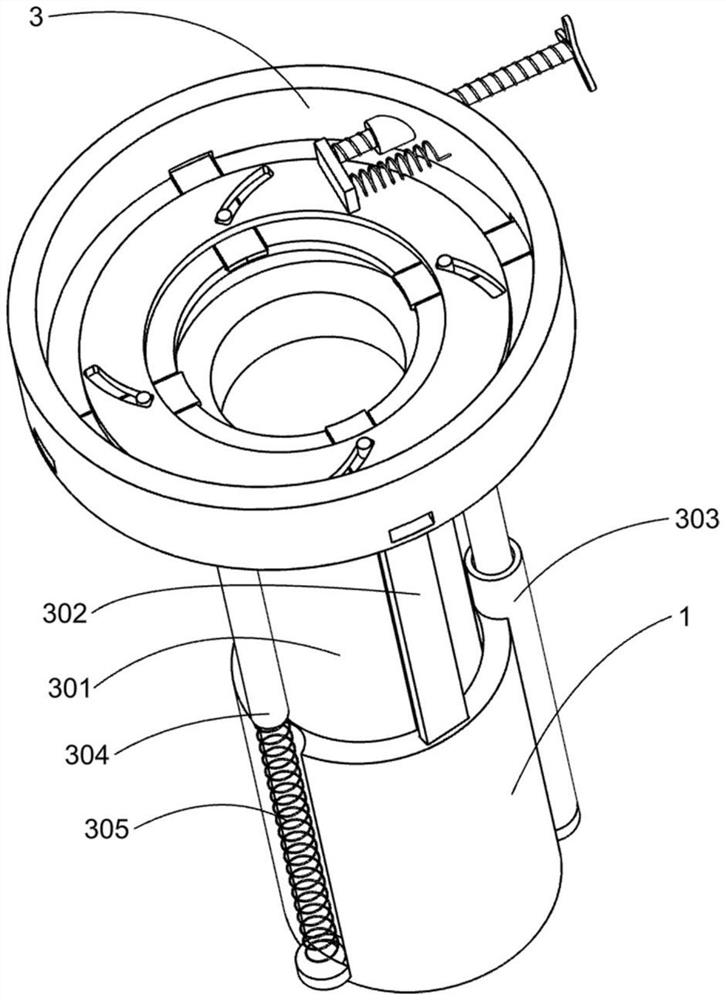

[0032] Next, the clamping screw 406 is rotated to move the clamping screw 406 into the hollow frame 401, and the hollow turntable 404 is pushed to rotate. The center direction of the frame 401 moves, and the four sliding clamping rods 402 move inward to fix the drill bit of the electric hammer and the device.

[0033] When the worker uses the electric hammer to work, the worker starts the electric hammer, and then presses the electric ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com