Machine head for strapping machine and strapping machine

A technology of a strapping machine and a machine head, which is applied to the parts and strapping materials of the strapping machine, can solve the problems of damage, low reliability of use, cumbersome disassembly and assembly process, etc., so as to improve the reliability of use, achieve balanced force, The effect of improving packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

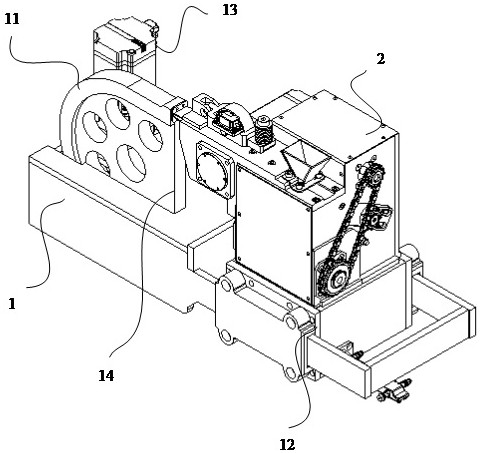

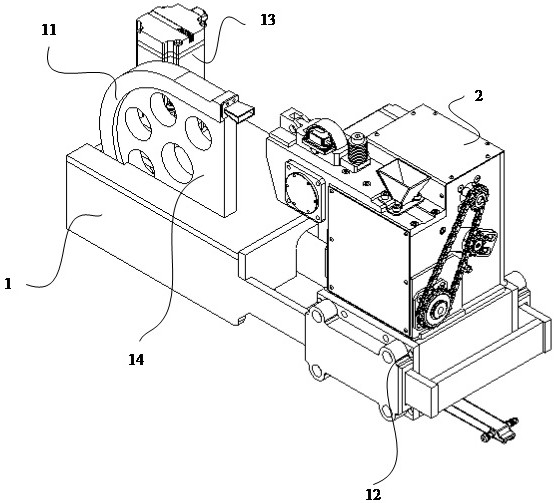

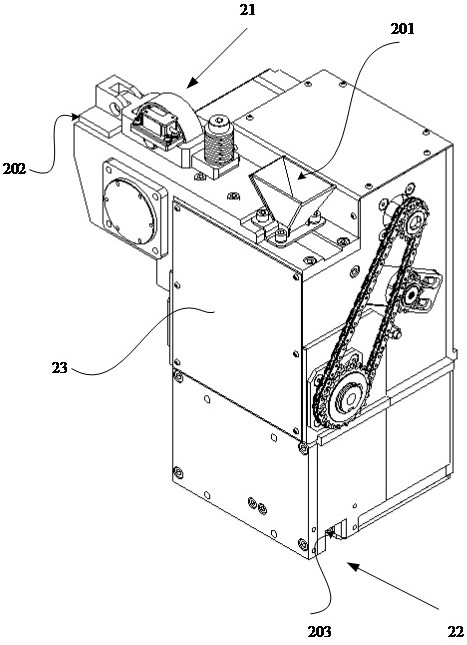

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] The invention provides a strapping machine, which includes a strapping machine head, a packing chute and other accessory parts in a conventional strapping machine. Among them, the packing belt enters the strapping machine head and is transported into the packing chute, so that the packing belt wraps around the goods, and then, the packing belt is tightened, welded and cut by the strapping machine head to realize the packing of the goods. Complete the packaging process. For the specific structural form of the packaging chute and other accessory parts in the strapping machine, reference can be made to the configuration in a conventional strapping machine, and no limitation or description will be made here.

[0028] For the strapping head, in order to meet the requirements of easy disassembly and improve the reliability of use, the following structural improveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com