Elevator balance compensation chain with high self-lubricating stability

A technology with strong stability and balance compensation, applied in the field of elevator compensation chain, it can solve problems such as failure to meet environmental protection requirements, gravity deviation, lack of self-lubricating function, etc., to enhance flexibility and flame retardancy, and reduce rotational friction. coefficient, the effect of increasing the high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

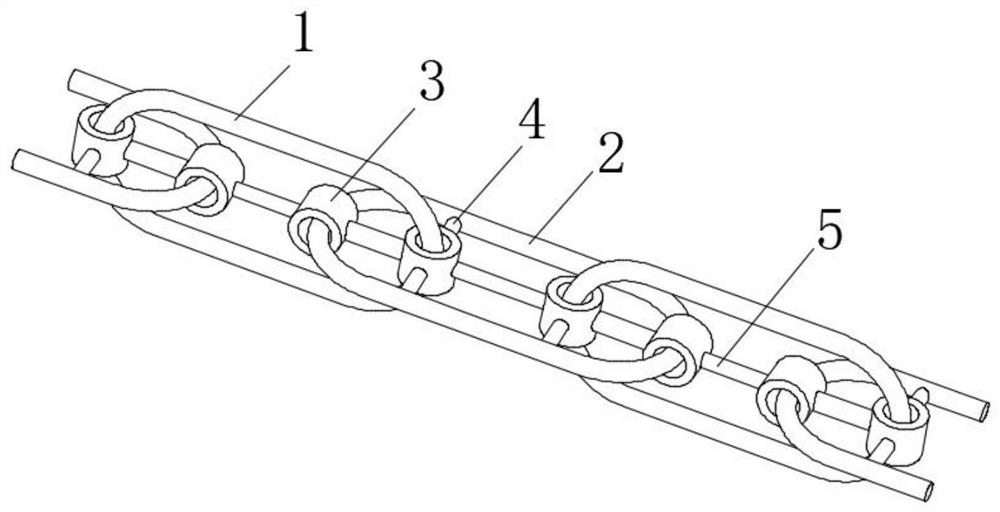

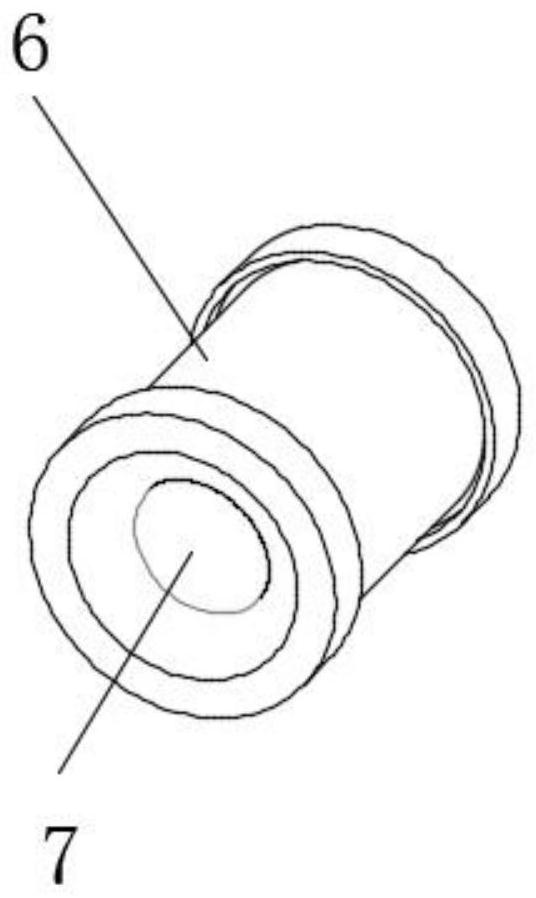

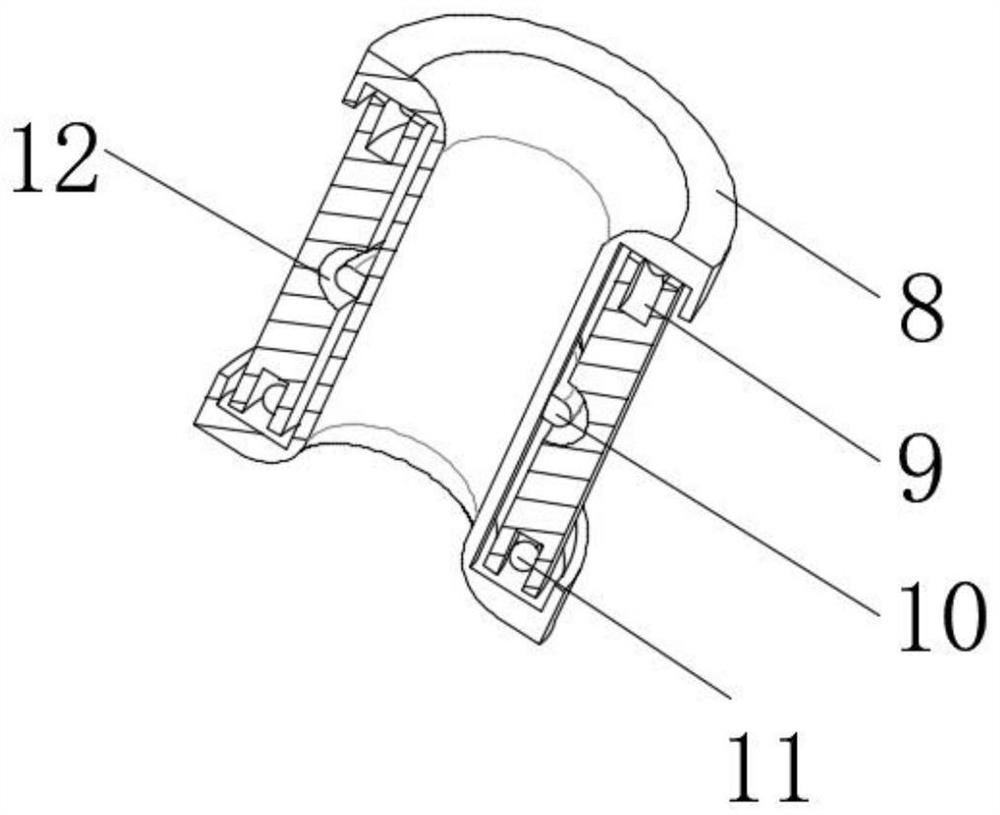

[0021] see Figure 1-4 , an elevator balance compensation chain with strong self-lubricating stability, including the first chain ring 1 and the second chain ring 2, the first chain ring 1 and the second chain ring 2 are flexibly socketed, and the first chain ring 1 is close to the second chain ring One end of the chain ring 2 and the end of the second chain ring 2 close to the first chain ring 1 are both sleeved with a collar 3, that is, when the second chain ring 2 rotates relative to the first chain ring 1, the second chain ring 2 is far away from the first chain ring 1. One end of the chain ring 1 will be close to or far away from the first chain ring 1. It can be, but not only, the collar 3 provided at both ends of the first chain ring 1 and the second chain ring 2, the first chain ring 1 and the second chain ring 2 When the two chain rings 2 rotate relative to each other, the first chain ring 1 and the second chain ring 2 rotate in the collar 3, which greatly reduces the...

Embodiment 2

[0023] Based on Example 1, such as Figure 1-4 , the two sides of the collar 3 are fixedly connected with flexible reinforcing ribs 4, the number of flexible reinforcing ribs 4 on each collar 3 is two, and the other end of the flexible reinforcing ribs 4 is connected with the first chain ring 1 and the second chain ring 1 respectively. Both sides of the chain ring 2 are fixedly connected, so that the position of the collar 3 is limited, and the position of the collar 3 can be limited while the first chain ring 1 and the second chain ring 2 can only produce relative rotation without It will produce relative movement, which can reduce the shaking of the compensation chain during the operation of the elevator, which is beneficial to the stability of the elevator during operation. The flexible reinforcing rib 4 is woven by tough material, and the flexible reinforcing rib 4 is soaked in lubricating oil, so that the first The rotation process of the chain ring 1 and the second chain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com