Novel textile equipment with textile dust collecting device

A collection device and textile equipment technology, applied in the direction of textiles and papermaking, etc., can solve the problems of explosion, poor collection effect and limited effect of textile dust, and achieve the effect of increasing the collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

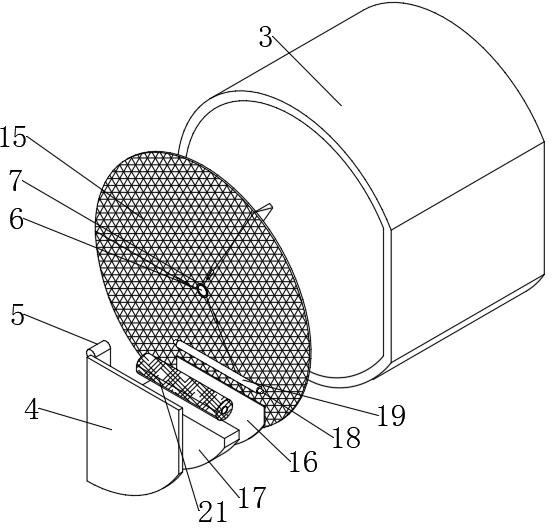

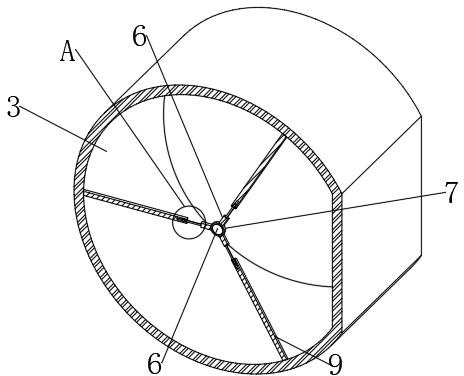

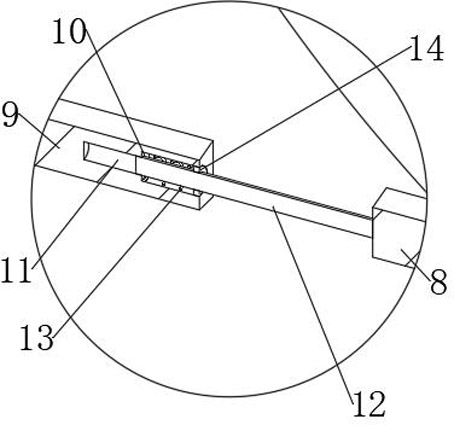

[0035] see Figure 1-6, a new type of textile equipment with a textile dust collection device, comprising a textile equipment main body 1 and a textile dust collection device 2, the textile dust collection device 2 is placed on the side of the textile equipment main body 1, wherein the textile dust collection device 2 can be set separately , is designed to be movable, and can also be fixedly connected to the frame of the textile equipment main body 1. This is a well-known technology for those skilled in the art. Those skilled in the art can make a reasonable design according to the working environment of the textile equipment main body 1. The textile dust collection device 2 includes an outer shell 3, an L-shaped baffle 4 is fixedly connected to the opening of the outer shell 3, and an installation platform 5 is fixedly connected to the upper end of the L-shaped baffle 4, and a fan blade shaft 6 is rotatably connected to the installation platform 5. The outer side of the blade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Void diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com