Bamboo fiber and chemical fiber interwoven fabric and weaving method

A bamboo fiber and fabric technology, applied in plant fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of non-wear resistance, easy hair loss and broken yarn, etc., and achieve the effect of maintaining strength, short baking time and improving resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

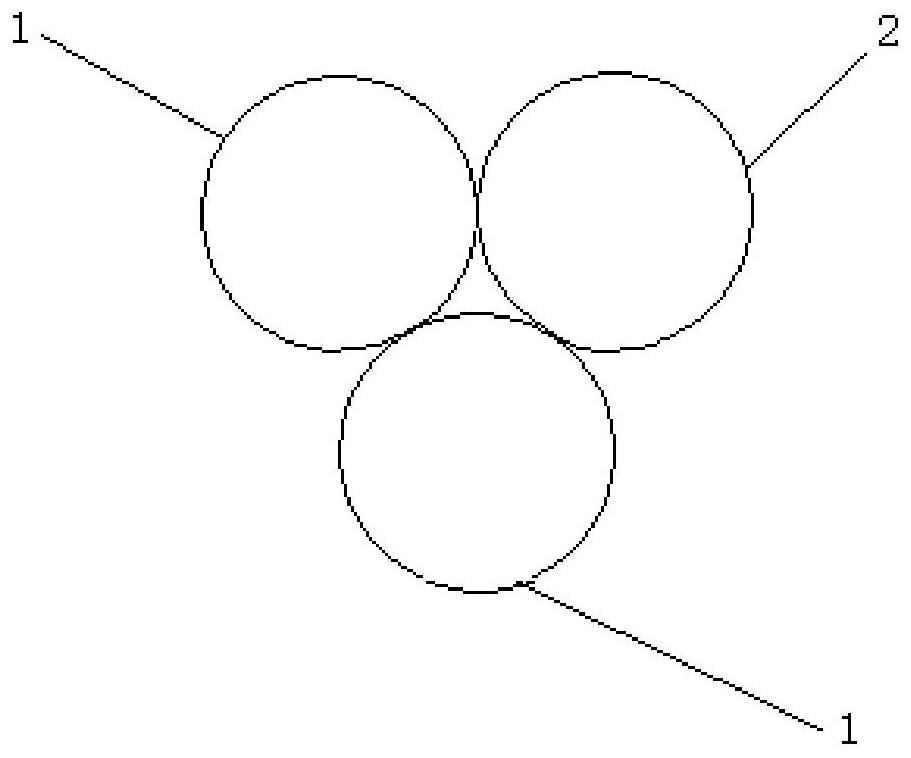

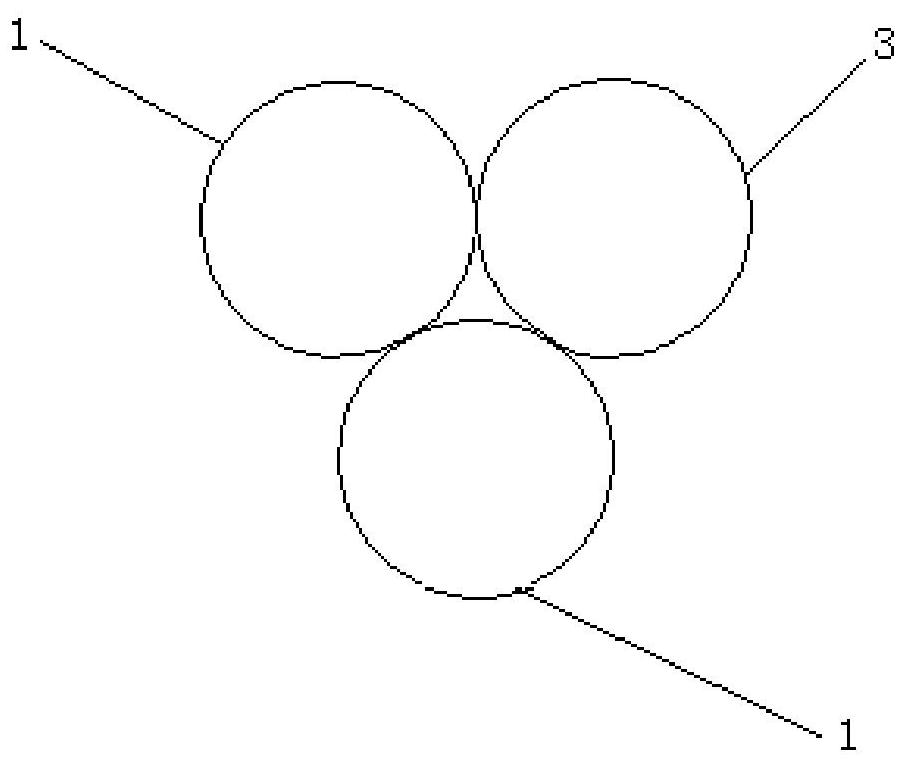

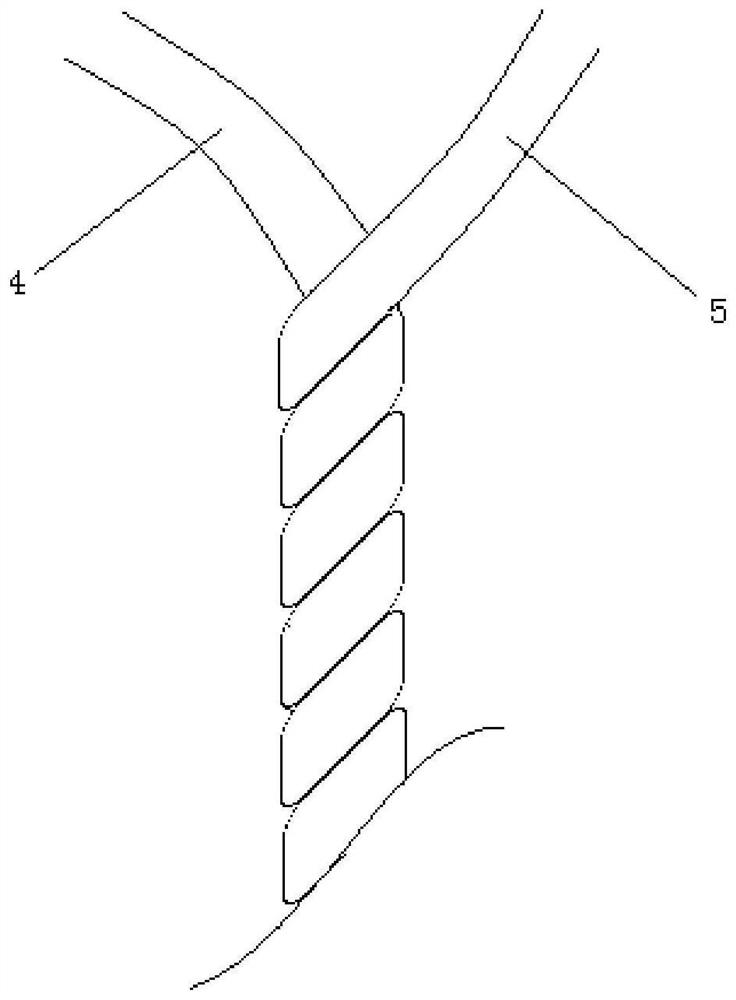

[0023] This embodiment proposes a kind of bamboo fiber chemical fiber interweaving fabric, described fabric is formed by interweaving warp yarn and weft yarn, and described fabric front shows warp yarn, and back shows weft yarn, and described warp yarn adopts polyester fiber, and described weft yarn is made of bamboo fiber 2, Modal fiber 2 and viscose fiber 3 are blended, bamboo fiber single yarn and modal single yarn are twisted into the first strand 4 in the ratio of 2:1, bamboo fiber single yarn and viscose fiber single yarn are in the ratio of 2:1 The ratio is twisted into the second strand 5, the first strand and the second strand are twisted into the weft yarn in a ratio of 1:1, and the fabric is warp satin. The radial density of the fabric is 135 threads / inch, and the wef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com