Mortise and tenon type machine frame used for liquid rocket engine

A liquid rocket and engine technology, applied in the field of tenon-and-mortise frame, can solve the problems of reducing fatigue strength, reducing bearing capacity, stress concentration at welded joints, etc., and achieving the effects of improving quality, small deformation and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

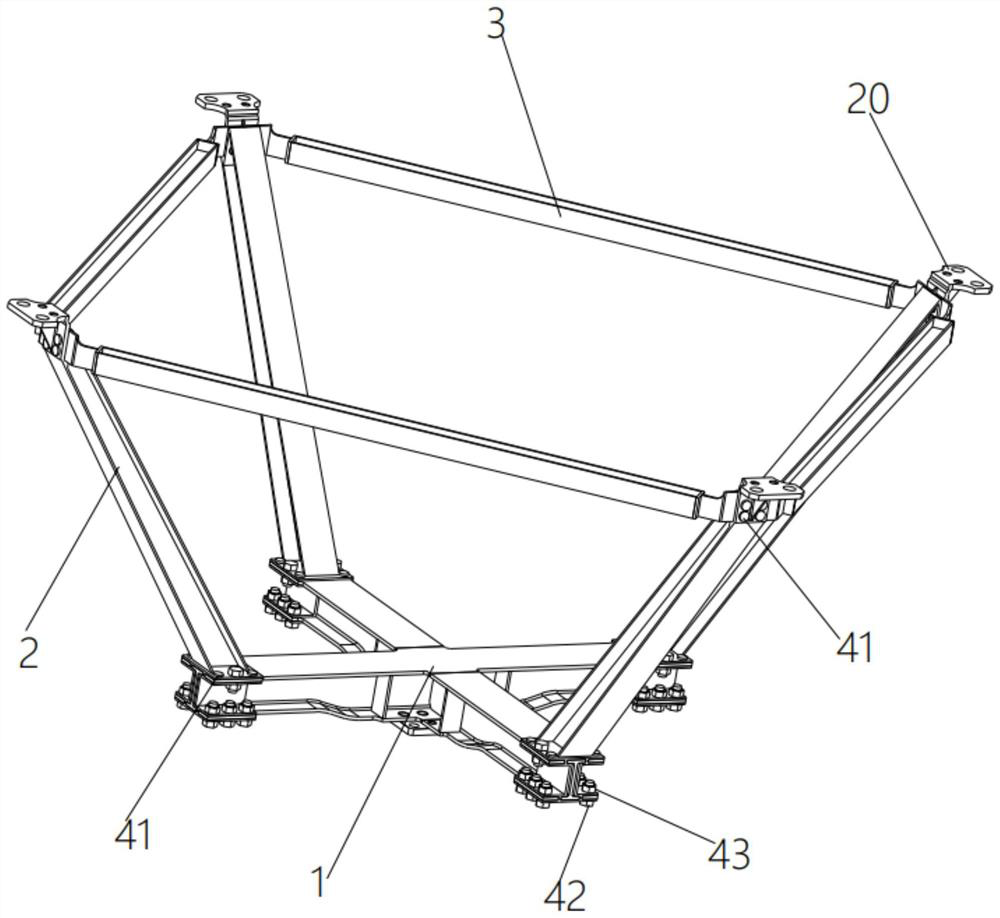

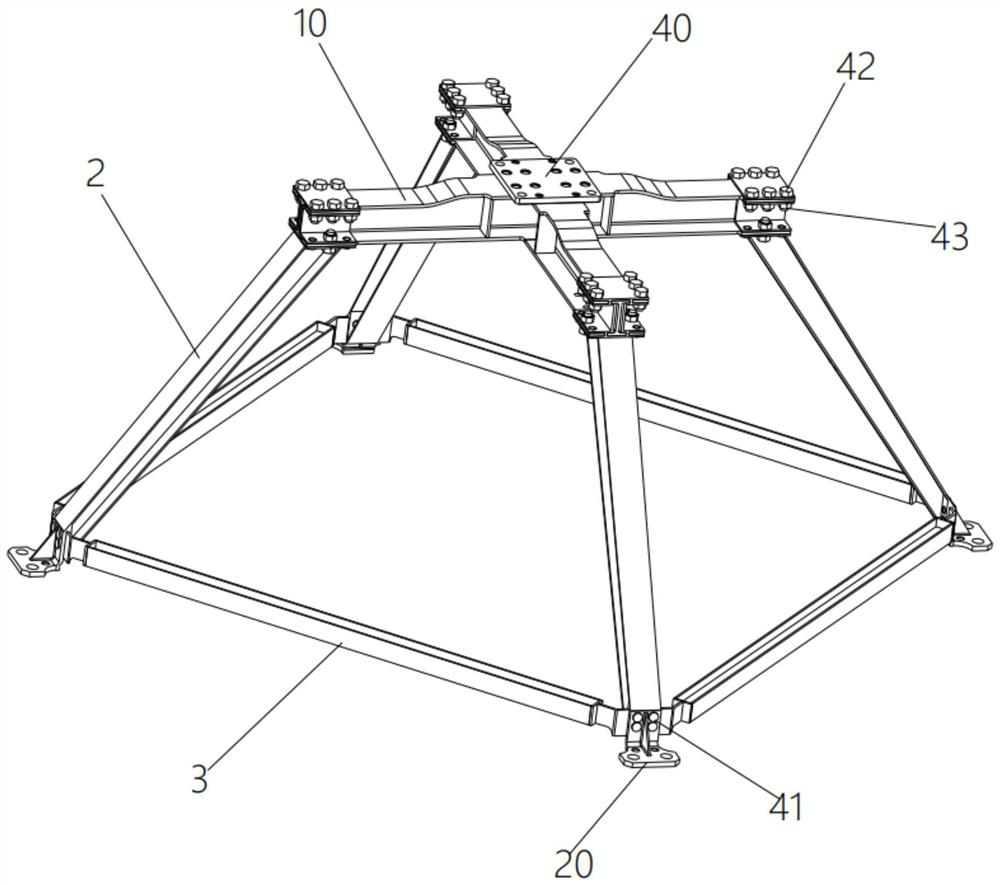

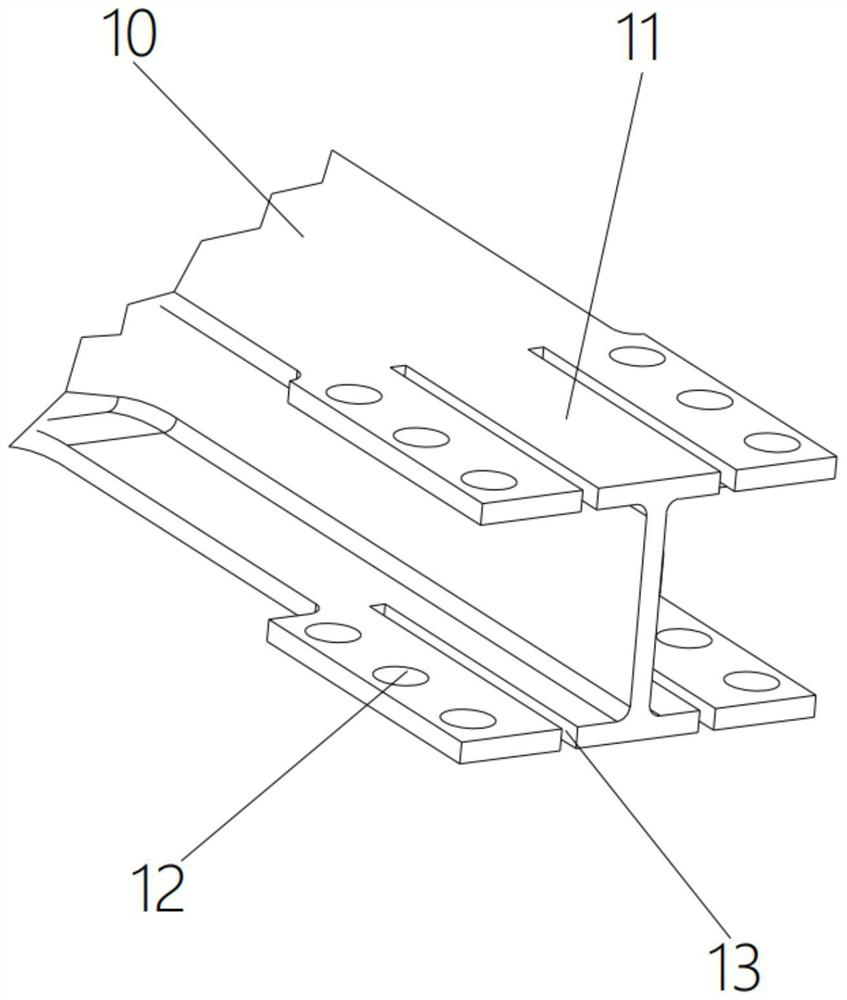

[0031] Such as Figure 1-6 As shown, the present invention discloses a mortise and tenon frame for a liquid rocket engine, comprising a cross beam 1, a load-bearing beam 2 and a cross beam 3, the cross-sections of the cross beam 1, load-bearing beam 2 and cross beam 3 are I-shaped, with mortise and tenon plugs 11 at the four ends of the cross beam 1, the number of bearing beams 2 is four, and the lower end of each bearing beam 2 is provided with a mortise and tenon joint that fits with the mortise and tenon plugs 11 The socket 21, through the insertion of the mortise and tenon plug 11 and the tenon and tenon socket 21, inserts and fixes the four load-bearing beams 2 on the four ends of the cross beam 1 respectively, and two Mortise and tenon slots 25, two mortise and tenon slots 25 are arranged on both sides of the upper end of the load-bearing beam 2, the number of beams 3 is four, and the four beams 3 are respectively arranged between every two adjacent load-bearing beams 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com