Method for measuring residual stress of polycrystalline material in X-ray diffraction full-spectrum multi-peak fitting mode

A polycrystalline material and residual stress technology, applied in the field of analysis and testing, can solve problems such as errors and achieve the effect of avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

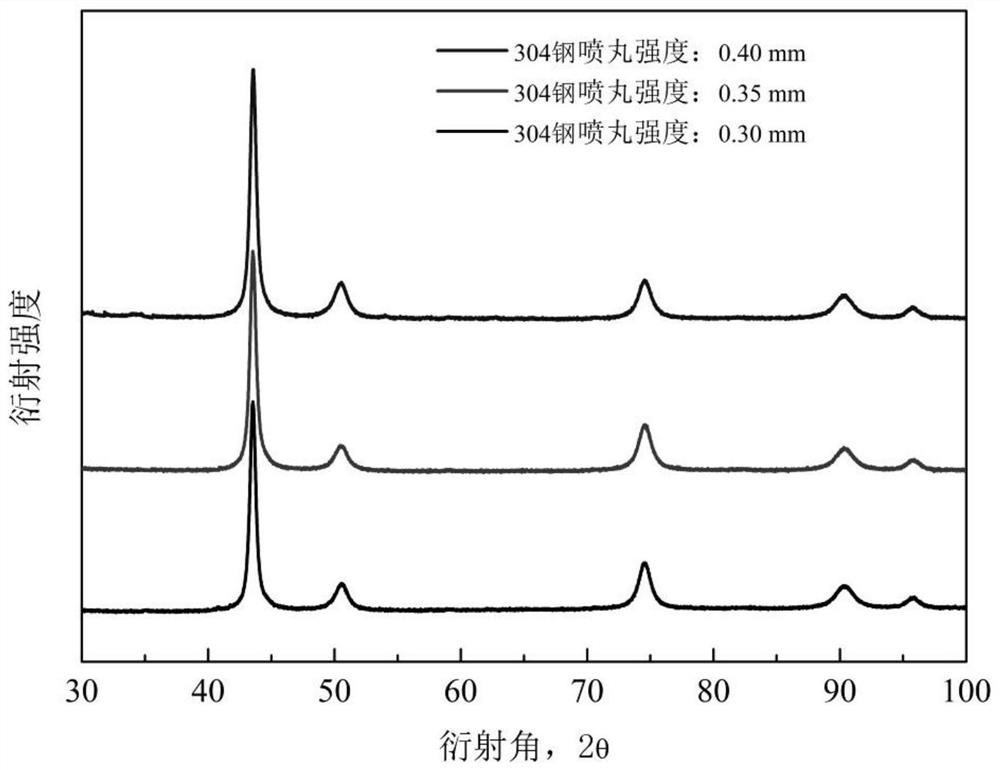

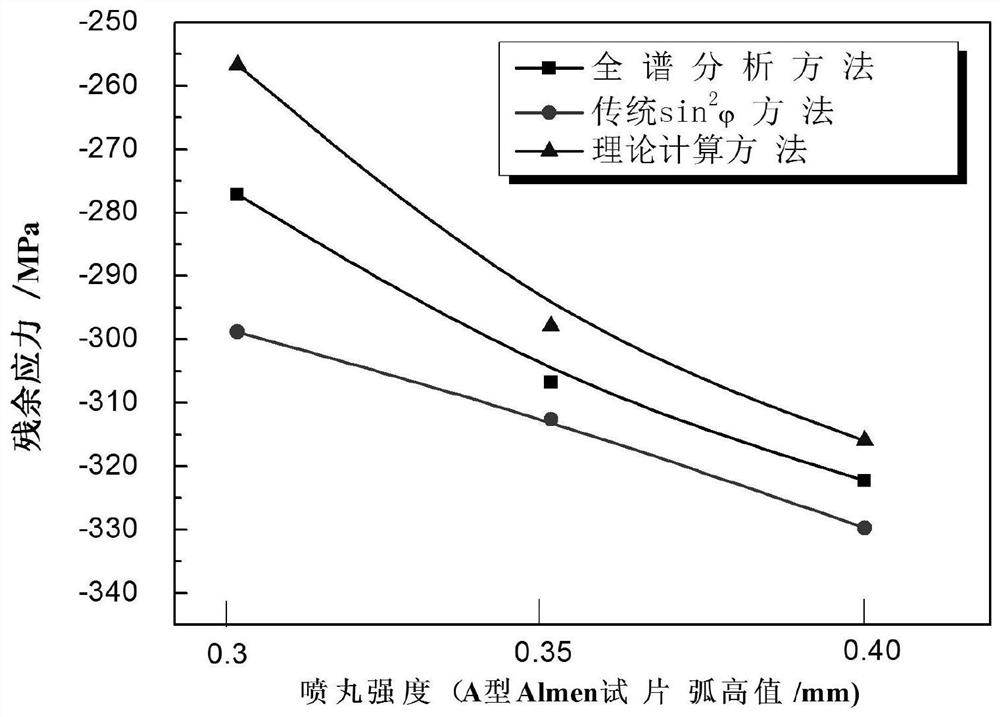

[0047] The polycrystalline material sample is 304 austenitic stainless steel, the sample size is 20mm×20mm×5mm, and it is divided into three groups. Using pneumatic shot blasting machine and The high-strength steel wire cut shot, the surface of the sample is shot peened, and the three groups of shot peening intensity (indicated by the arc height value of the A-type Almen test piece) are: 0.30mm, 0.35mm, 0.40mm.

[0048] Material X-ray Diffraction Full Spectrum Measurement Parameter Setting

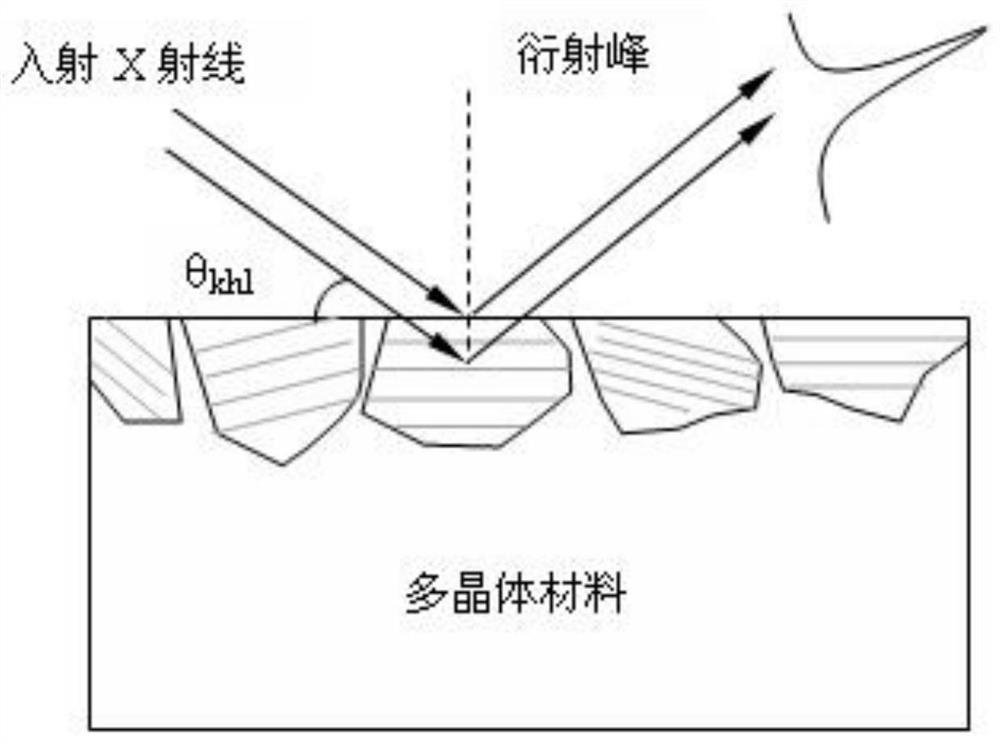

[0049] Such as figure 1 As shown, the specific X-ray diffractometer measurement parameters in the experiment are tube voltage: 40kV, tube current: 30mA, Cu-K α For radiation, the scanning speed is 2° / min, the scanning step is 0.01°, and the scanning range is set to 35°-100°.

[0050] X-ray diffraction lines of 304 austenitic stainless steel with different shot peening intensities were obtained by X-ray diffractometer.

[0051] Using a diffractometer (Rigaku UltimaⅣ), according to the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com