Deep rock sampling device for geological exploration

A rock sampling and geological exploration technology, applied in the field of deep rock sampling, can solve the problems of severe vibration of sampling device, wear of sampling drill bit, unstable sampling process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

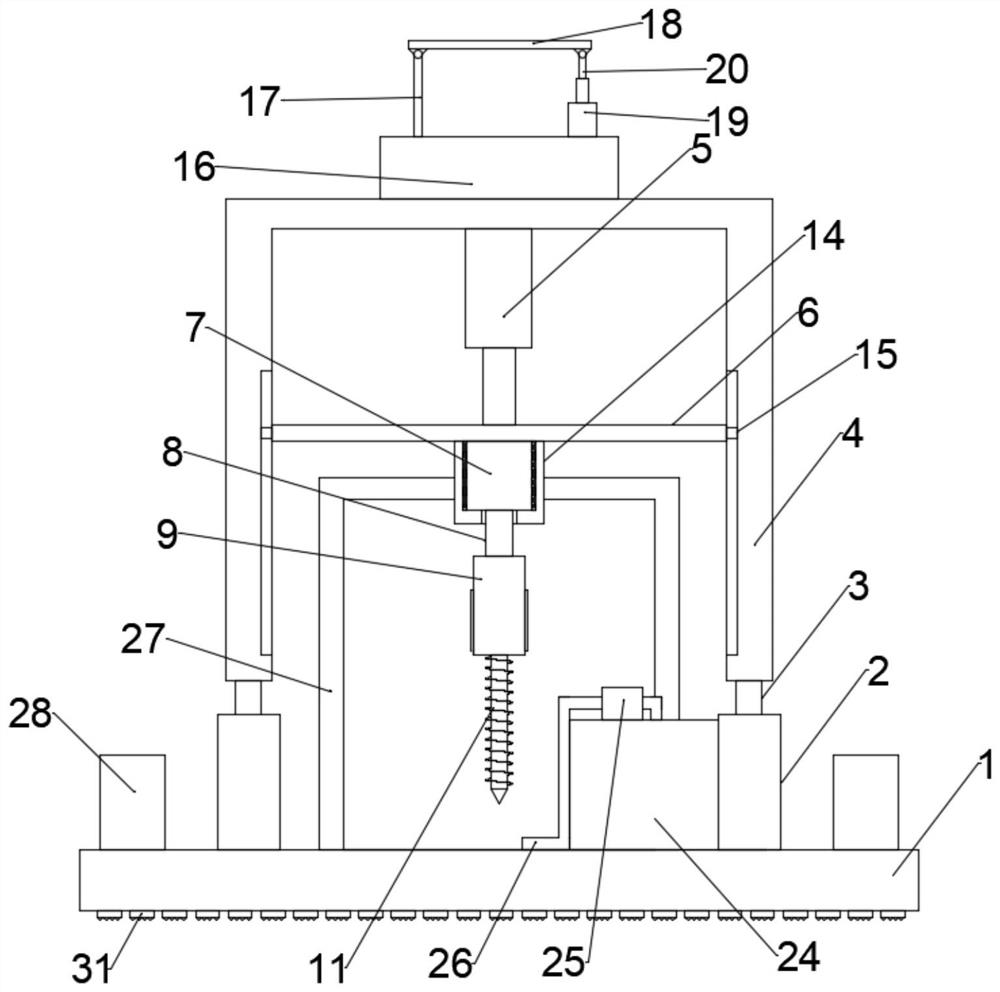

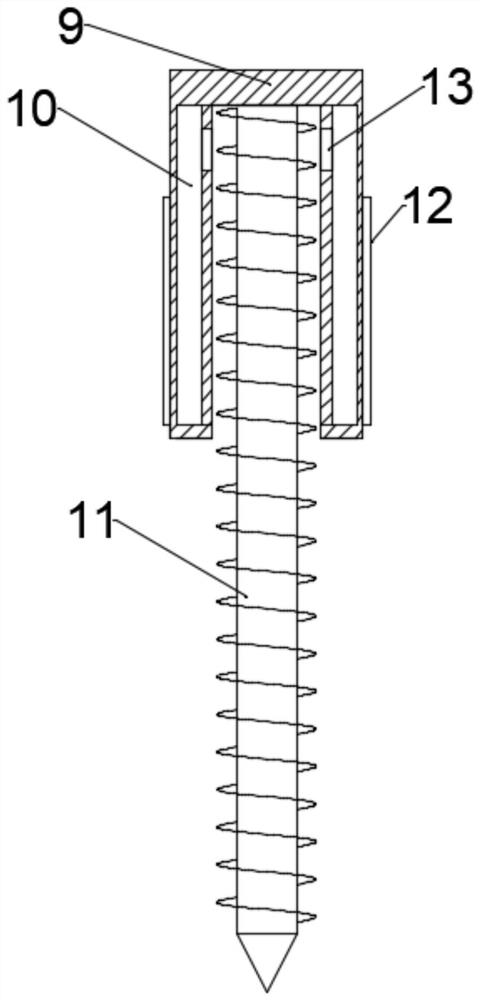

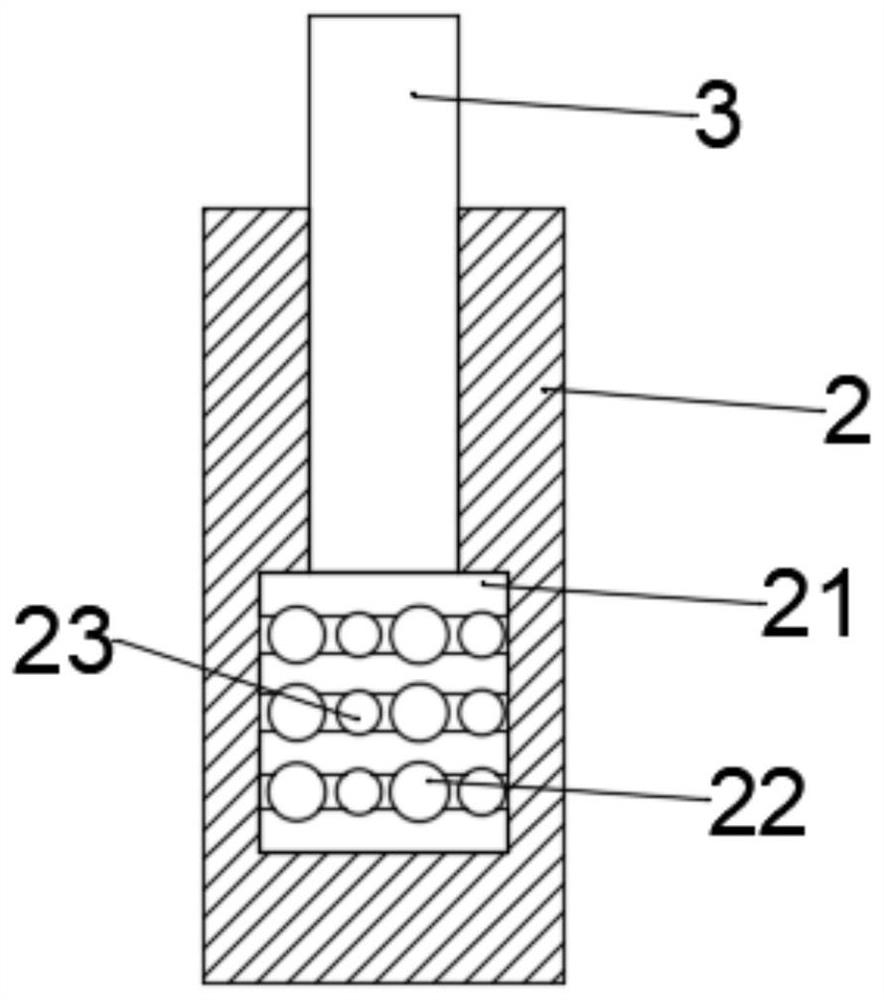

[0025] combine Figure 1-5 , a deep rock sampling device for geological exploration, including a base 1, a plurality of sleeves 2 are fixed on the upper end of the base 1, and a moving rod 3 is slidably connected to the upper ends of the plurality of sleeves 2, and the moving rod 3 and the sleeve 2 is provided with a shock absorbing mechanism, the upper end of the moving rod 3 is fixed with a 匚-shaped mounting frame 4, and the upper end of the inner side of the 匚-shaped mounting frame 4 is installed with a first electric push rod 5, the first The movable end of the electric push rod 5 is connected with a mounting plate 6, and the two ends of the mounting plate 6 are fixed with a slide block 15, and the inner walls of both sides of the 匚-shaped mounting frame 4 are provided with chute, and the slide block 15 and The chute is slidingly connected, the lower end of the mounting plate 6 is fixed with a motor 7, the output end of the motor 7 is equipped with a rotating shaft 8, the ...

Embodiment 2

[0038] combine figure 1 with Figure 4 , a deep rock sampling device for geological exploration, this embodiment further limits the present invention on the basis of embodiment 1.

[0039] A plurality of fixed frames 28 are installed on the upper end of the base 1, a third electric push rod 29 is installed in the plurality of fixed frames 28, and the movable ends of the third electric push rod 29 are connected with universal wheels 30, A through hole is opened on the base 1 and located at the universal wheel 30 , and a push rod 27 is fixed on the upper end of the base 1 .

[0040] Specifically, the universal wheel 30 is adjusted to the bottom of the base 1 through the third electric push rod 29, and is in contact with the ground, and the universal wheel 30 is used to realize the flexible movement of the device through the hand push rod 27. After moving to the sampling site, the The universal wheel 30 is adjusted to the inside of the base 1 through the third electric push rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com