Gas tank supporting platform

A technology for supporting platforms and gas tanks, applied in gas/liquid distribution and storage, lifting devices, lifting frames, etc., can solve problems such as inconvenient use, stop at the theoretical stage, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

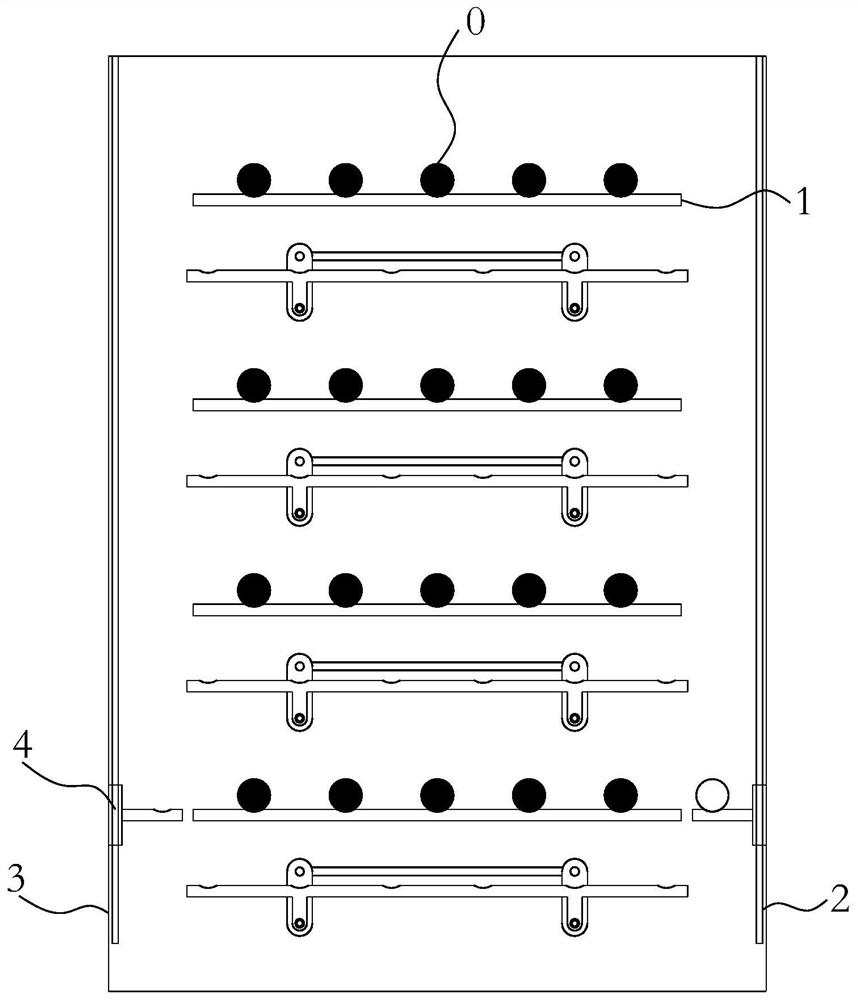

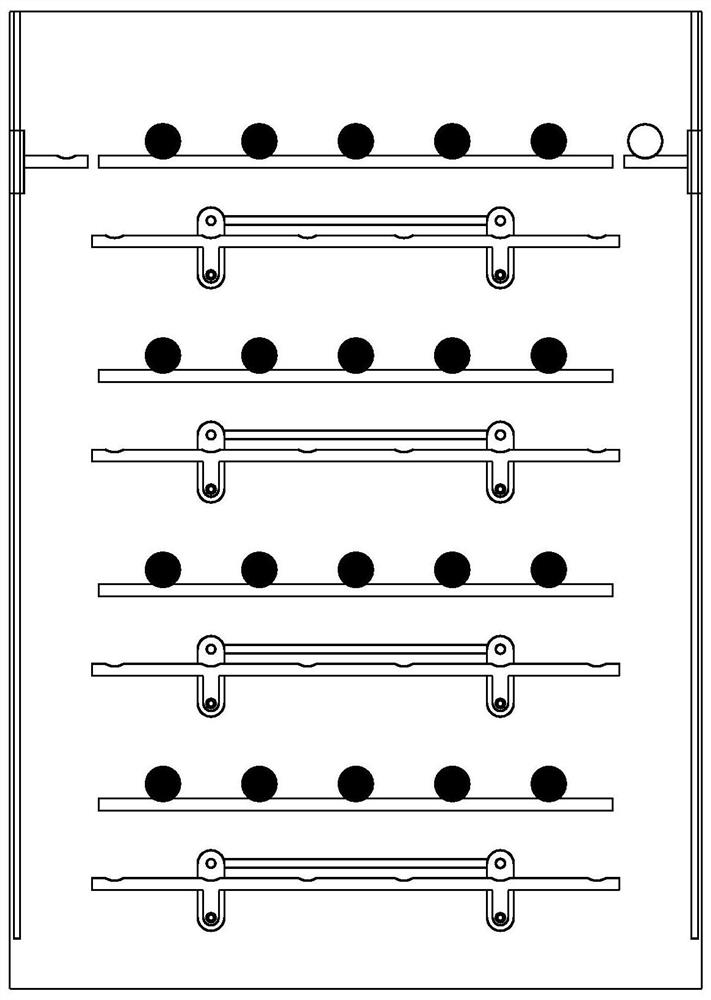

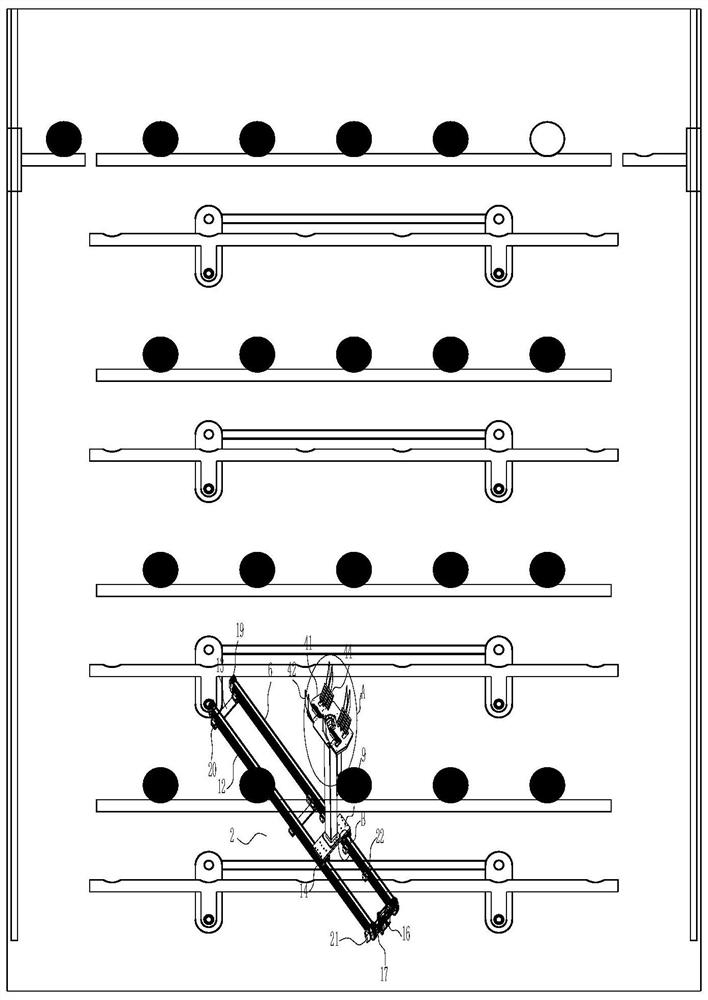

[0026] combine Figure 1-12 As shown, a gas tank support platform is mainly used to realize gas tank circulation and gas tank pick-and-place inside the tank changing station, such as figure 1 As shown in the figure, the square area corresponds to the tank changing station, and the gas tank supporting platform includes the gas tank supporting platform including the multi-layer support frame 1 set in the tank changing station, and the gas tank O can be transported to each layer of support frame 1 And the vertical conveying device 4 of the tank inlet 2 and the tank outlet 3 of the tank changing station. Such as figure 1 As shown in , there are 4 layers of supporting frames 1 in the figure. In fact, according to actual needs, it can be flexibly set to be more or less. The function of the support frame 1 is mainly to place and store the gas tank 0 , and at the same time realize the replacement of the gas tank 0 on the support frame 1 and the vertical conveying device 4 . The mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com