Feeding device for automatic production line of brake caliper support

An automatic production line and brake caliper bracket technology, applied in packaging, conveyors, conveyor objects, etc., can solve the problems of low production efficiency, inconvenient grasping, increase production costs, etc., and achieve improved feeding efficiency and convenient grasping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

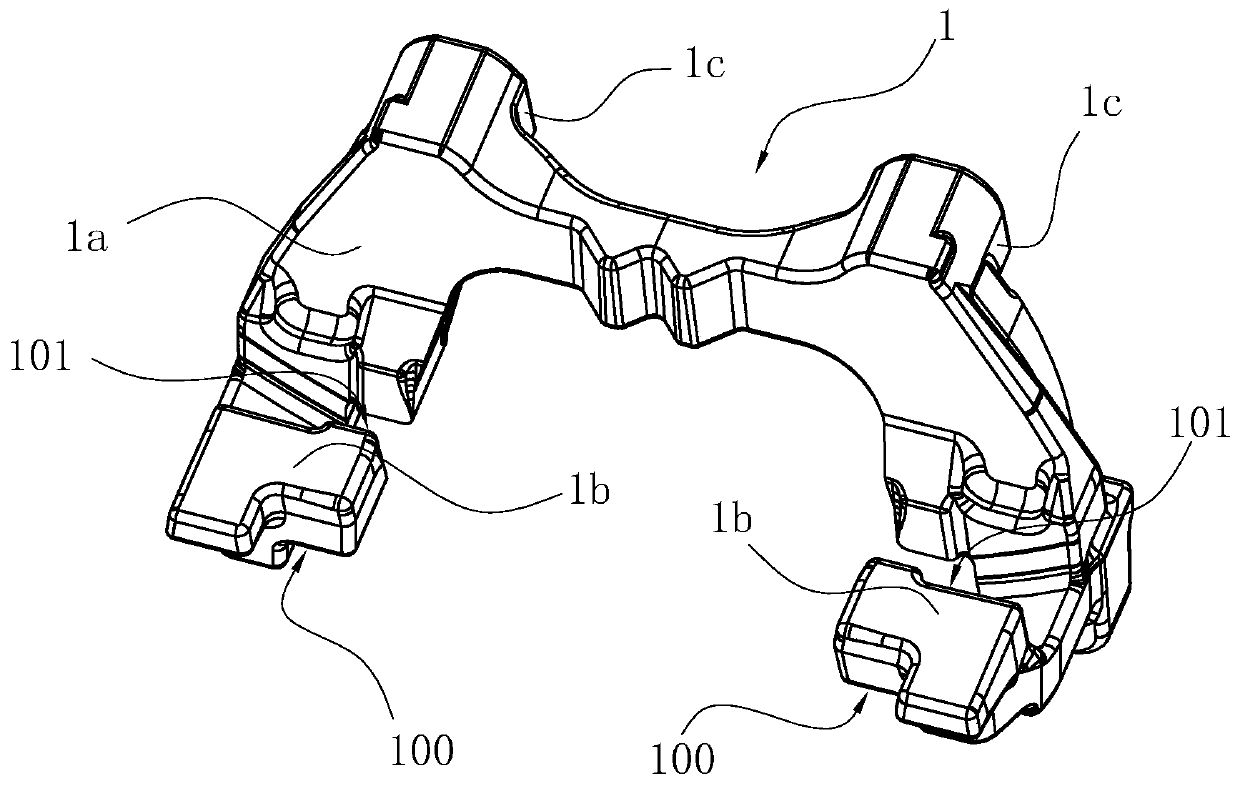

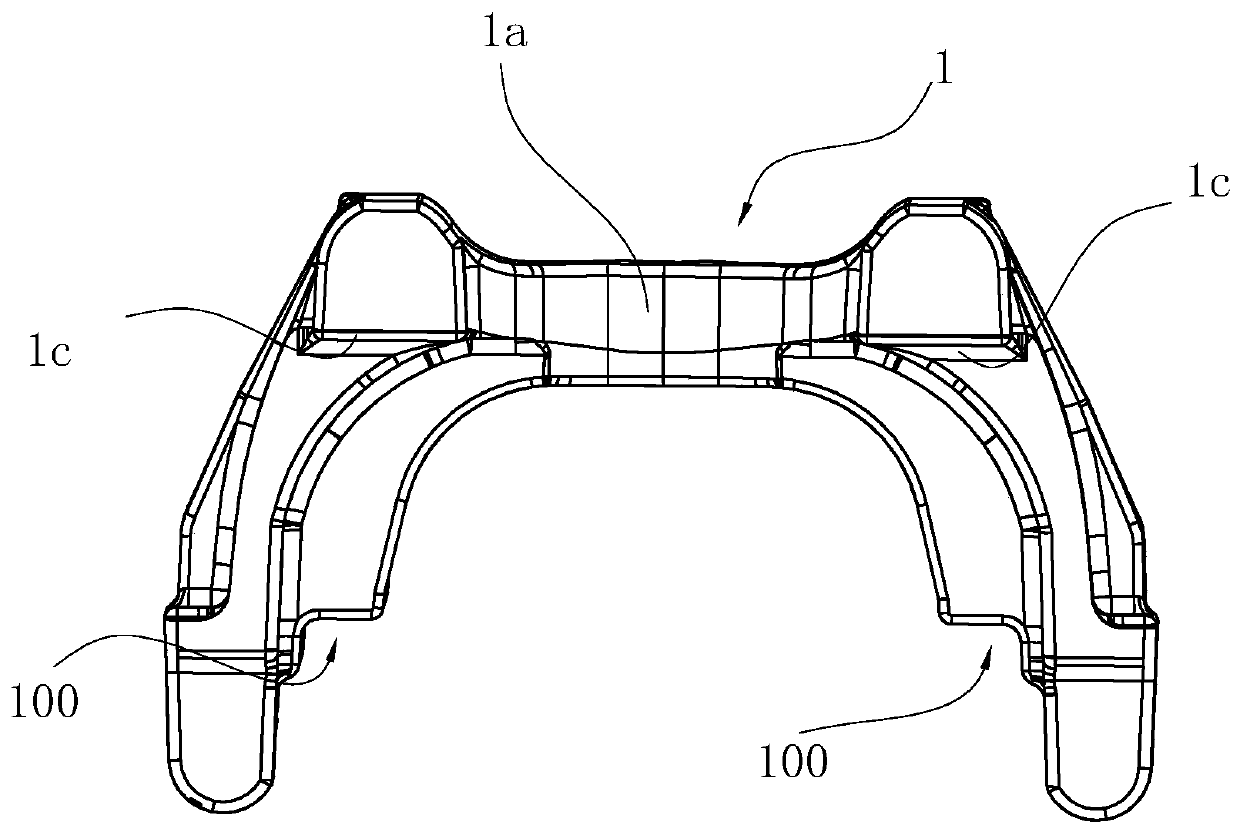

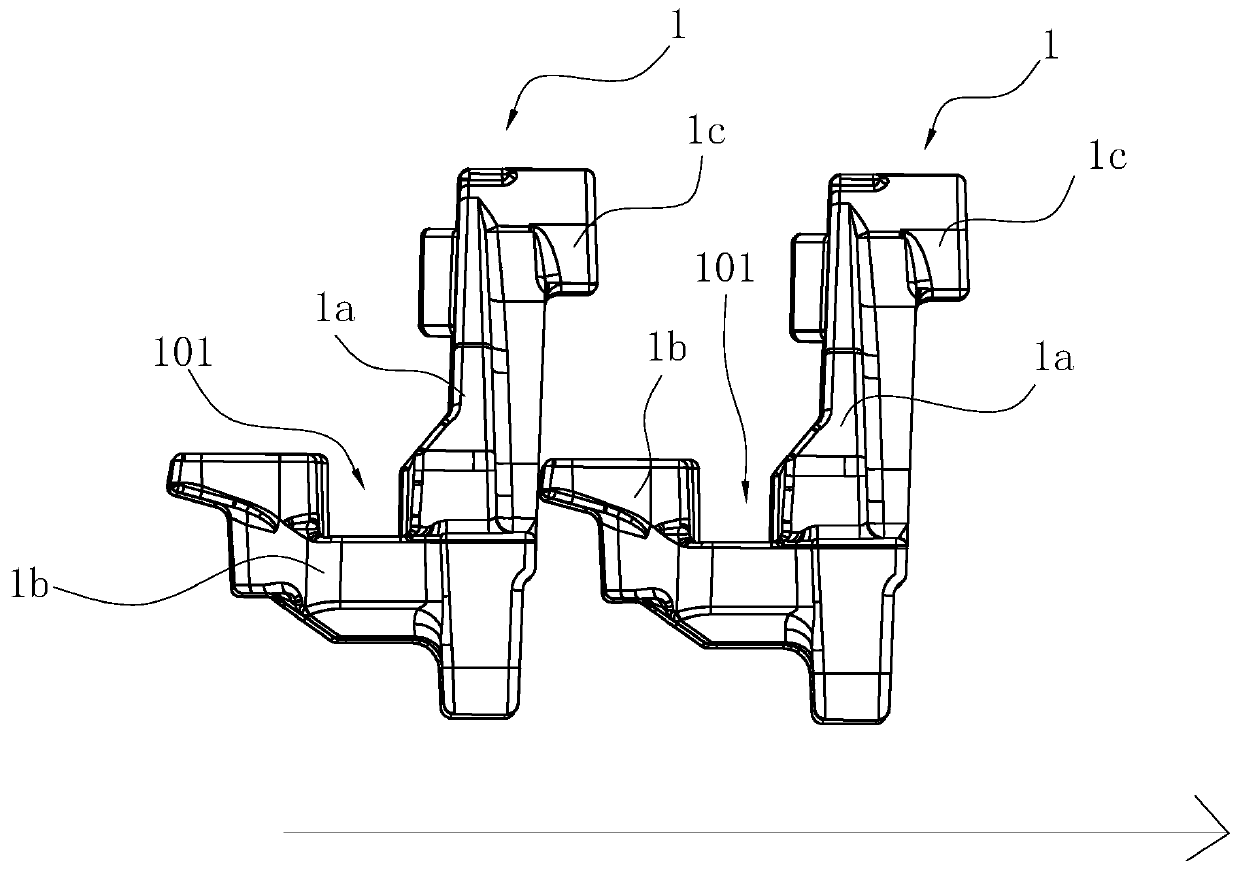

[0032] see Figure 1-Figure 3 The structure of the brake caliper bracket 1 for automobiles is an irregular shaped body, which specifically includes a bracket body 1a, a side portion 1b extending backward on both sides of the bottom of the bracket body 1a, and protruding forward on both sides of the upper part of the bracket body 1a. The protrusion 1c, wherein, the bracket body 1a is an irregular approximately bridge-shaped plate, its two ends are downward, and the middle is upward compared with the two ends. Specifically, the bottom of the brake caliper bracket 1 has two symmetrical The resting grooves 100 , the extension direction of the two resting grooves 100 is consistent with the extension direction of the two side parts 1 b of the brake caliper bracket 1 .

[0033] see Figure 1-Figure 14 , the feeding device of the automatic productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com