A bar automatic unbundling device

A bar material and automatic technology, applied in packaging, transportation and packaging, cutting and unsealing, etc., can solve the problems of single function, cumbersome unbundling work, no discharge and hardcover transportation, etc., and achieve good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0029] The invention discloses an automatic unbundling device for bars, which can unbundle the whole bundle of bars in the bundling device, specifically, cut the bundled strips of the whole bundle of bars for unbundling, and at the same time unbundle the unbundled bars. The bars are sorted and sent to the next process. The following are specific examples:

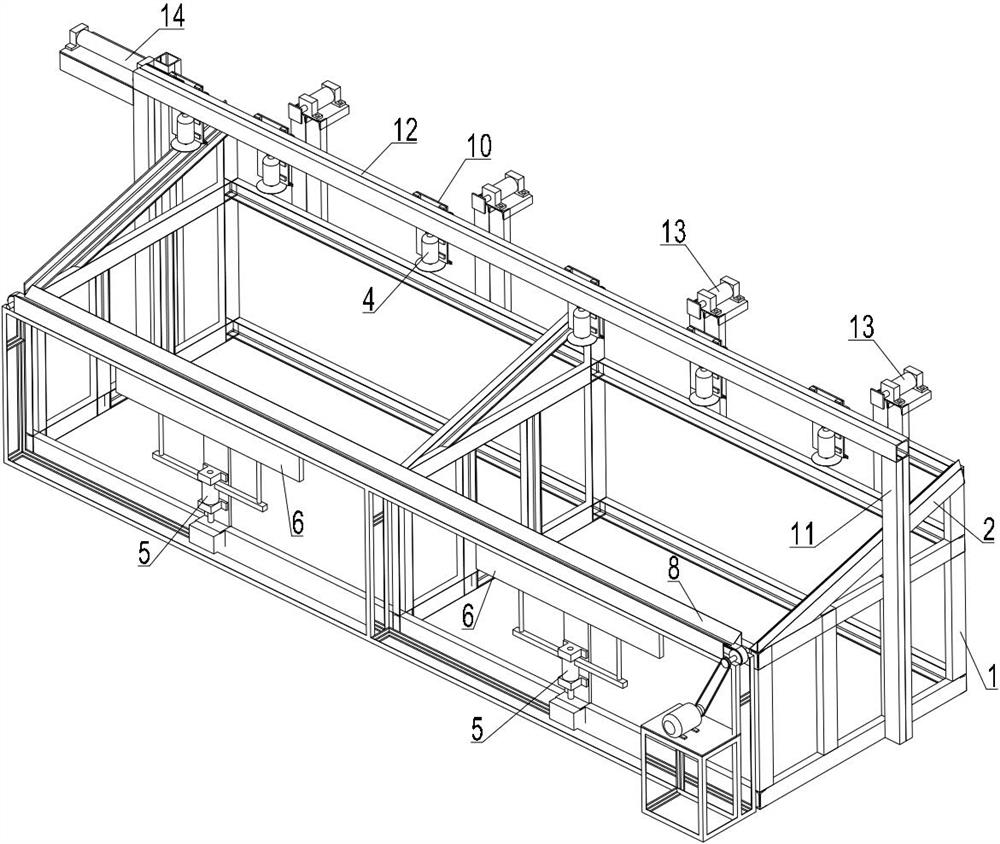

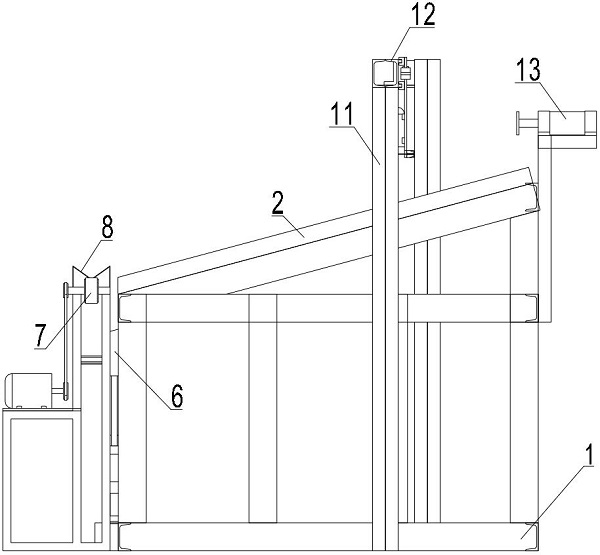

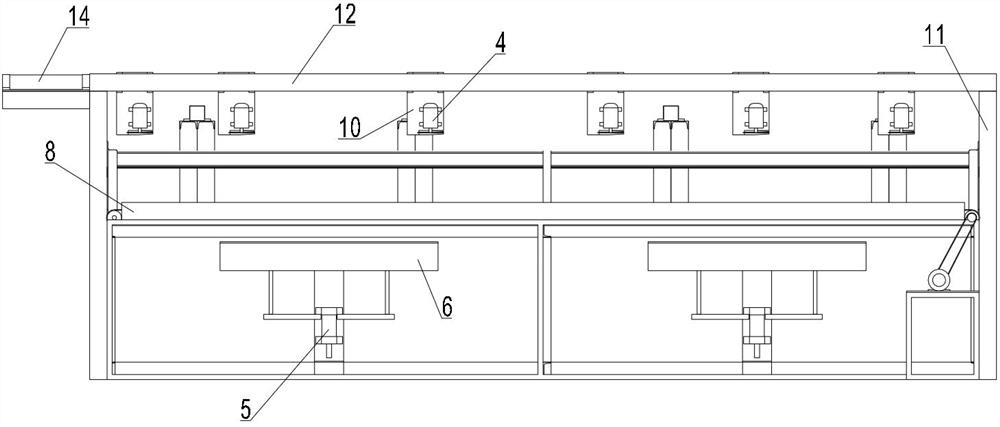

[0030] The present invention is an automatic unbundling device for bars, such as figure 1 As shown, including support assembly, unbundling assembly and feeding assembly. The support component is the basic support frame part of the device, the unbundling component is used to cut and unbundle the bars, and the feeding component is to sort and transport the unbundled bar sections.

[0031] Such as figure 1 , figure 2 As shown, the support assembly includes a bottom support frame 1 and an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com