A kind of saturated polar polymer and preparation method thereof

A technology of polar polymers and polymers, applied in the field of saturated polar polymers and their preparation, can solve problems such as poor saturation of polymers, achieve continuous adjustment of content and saturation, simple reaction operation, and high polymerization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

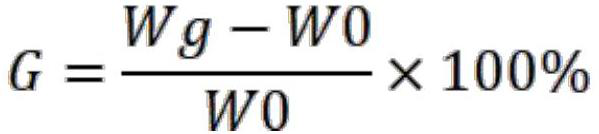

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of saturated polar polymer, it is characterized in that, comprises the following steps:

[0025] Mixing anionic surfactant, metal ion salt and water to obtain metal ion mixed solution;

[0026] Mixing the metal ion mixed solution, non-polar unsaturated polymer emulsion, hydrazine hydrate and hydrogen peroxide, and performing hydrogenation reduction modification to obtain a hydrogenation reduction modification product;

[0027] The hydrogenation reduction modified product is directly mixed with acrylonitrile monomer and a redox initiation system to carry out a graft polymerization reaction to obtain the saturated polar polymer.

[0028] In the present invention, unless otherwise specified, the raw materials used are all commercially available products in the field.

[0029] In the present invention, an anionic surfactant, a metal ion salt and water are mixed to obtain a metal ion mixed solution.

[0030] In the presen...

Embodiment 1

[0074] Place 30g of natural latex in a 500mL four-necked flask equipped with a stirring paddle, a separatory funnel and a reflux condenser, add deionized water to dilute to a latex solid content of 15%, and add 0.23g of sodium lauryl sulfate, After stirring for 15min, 0.008g of copper sulfate pentahydrate and 66.18g of hydrazine hydrate solution with a mass fraction of 80% were added in sequence; heated in an oil bath, keeping the reaction temperature at 50°C, 180g of hydrogen peroxide with a mass fraction of 30% was added dropwise through a separatory funnel to control The rate of addition was completed within 6 hours. After the addition was completed, the reaction was continued for 1 hour. The temperature was lowered to room temperature. Nitrogen was introduced into the system to remove oxygen. 24h, then add 0.068g tetraethylenepentamine, react at 25°C for 40h under nitrogen protection, then remove unreacted acrylonitrile by vacuum distillation, the latex adopts calcium chlor...

Embodiment 2

[0078] In this example, 30g of natural latex was placed in a 500mL four-necked flask equipped with a stirring paddle, a separatory funnel and a reflux condenser, deionized water was added to dilute until the latex solid content was 15%, and 0.23g of dodecyl was added. Sodium sulfate, after stirring for 15min, add 0.008g copper sulfate pentahydrate and 66.18g 80% hydrazine hydrate solution in turn; heat in oil bath, keep the reaction temperature at 50 ℃, add 180g 30% hydrazine hydrate dropwise through a separatory funnel Hydrogen peroxide, controlled the rate of addition, added within 6 h, after the addition was completed, continued the reaction for 1 h, cooled to room temperature, passed nitrogen into the system to remove oxygen, and added 12.6 g of acrylonitrile and 0.16 g of tert-butyl peroxide in sequence after 30 min Hydrogen, stirred for 24h, then added 0.34g of tetraethylenepentamine, reacted at 25°C for 40h under nitrogen protection, then removed unreacted acrylonitrile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com