48V electrically heated catalyst system for vehicle

A technology of electric heating and catalyst, applied in vehicle parts, electrochemical generators, batteries, etc., can solve problems such as poor low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

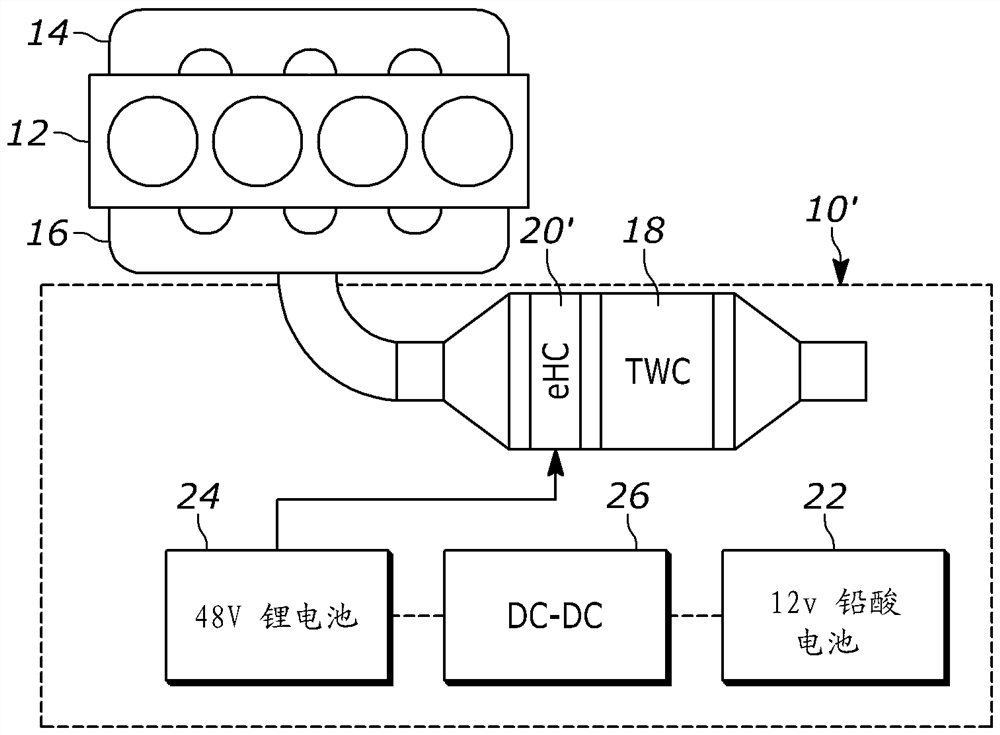

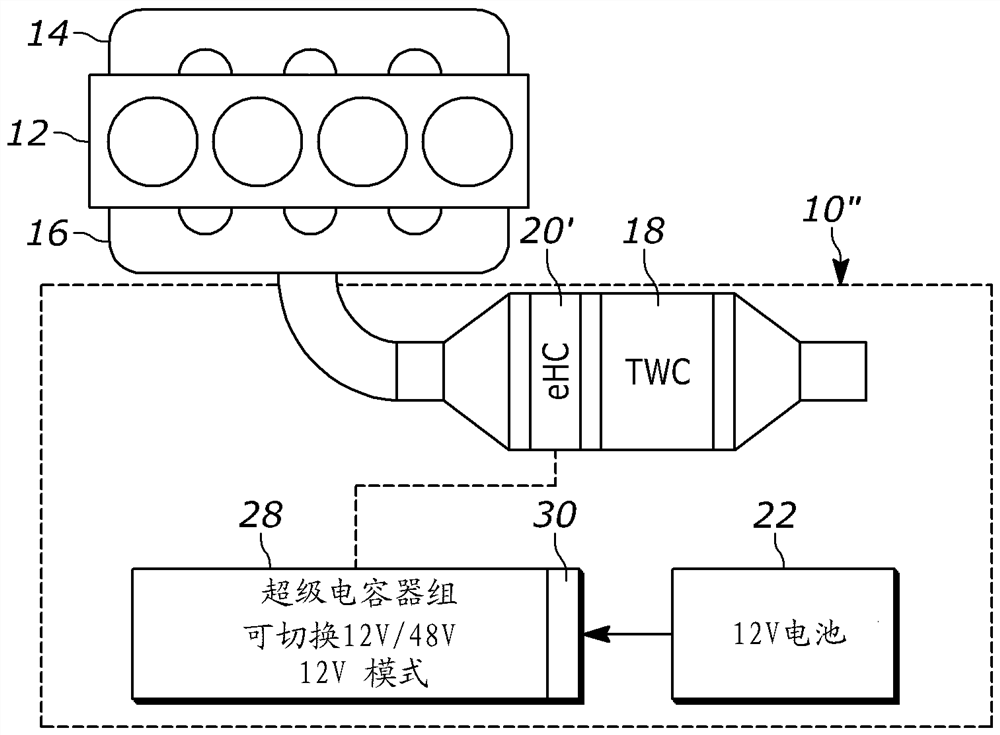

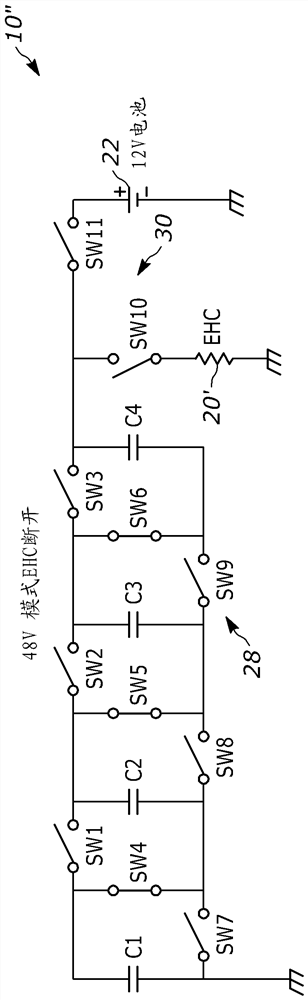

[0017] refer to image 3 , shows a vehicle exhaust system, generally indicated at 10 ″, for use with an internal combustion engine 12 having an intake arrangement 14 and an exhaust arrangement 16 according to an embodiment. The system 10 ″ includes a catalytic converter, preferably of the three-way type The exhaust device 18 is configured to be coupled to the exhaust device 16 . Catalytic converter 18 includes an electrically heated catalyst (EHC) 20' operating at 48V. According to this embodiment, an ultracapacitor structure or bank 28 is electrically connected between the EHC 20' and a 12V battery 22, preferably a lead-acid battery. Ultracapacitor bank 28 includes a plurality of individual ultracapacitors C1-C4 ( Figure 5A ), which are wired together to increase their voltage or power. Each supercapacitor C1-C4 can be an arrangement with multiple capacitors to achieve 12V. Supercapacitors are conventional electrical energy storage devices that have the ability to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com