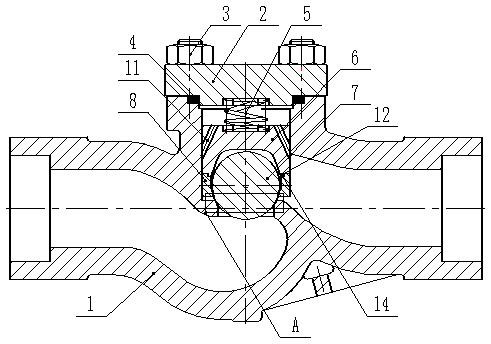

Low-pressure air-tight sealing spherical valve clack lifting check valve with ball holding device

A ball valve and ball-spinning technology, which is applied in the field of low-pressure air-sealed spherical disc lift check valves, can solve the problems of inability to achieve air-tightness, difficulty in realizing air-tightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

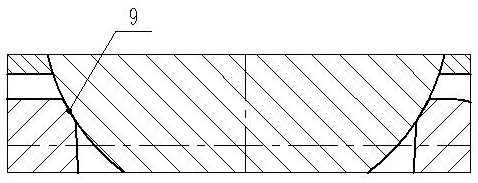

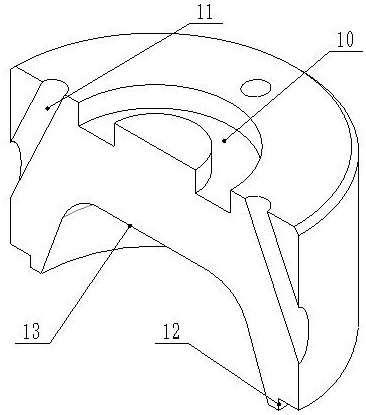

[0012] As shown in the figure, a low-pressure gas-sealed spherical disc lift check valve with a ball device includes a valve body 1, a valve cover 2, a gasket 4, a fastener 3, a spring 5, and a spherical disc 7. The sealing surface of the valve body 1 is an inclined plane, and the upper port of the valve body 1 is provided with a guide seat 6, a ball device 8, and a spherical disc 7, and the lower end surface of the guide seat 6 is provided with a convex positioning stop 12, and a convex positioning stop 12 cooperates with the grooved positioning spigot 14 that is provided with on the upper end surface of the ball pulling device 8, and the inside of the ball pulling device 8 is provided with a spherical surface consistent with the diameter of the spherical valve disc 7, and the upper end surface of the guide seat 6 and the valve cover The lower end surface is respectively provided with positioning grooves 10 for placing the spring 5, which avoids the possibility of the spring 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com