In-situ calibration device and method for measuring micro pneumatic force air floatation platform

An air-floating platform and in-situ calibration technology, which is used in measurement devices, force/torque/work measurement instrument calibration/testing, aerodynamic tests, etc. accuracy, reliability, and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further elaborated below in conjunction with embodiment.

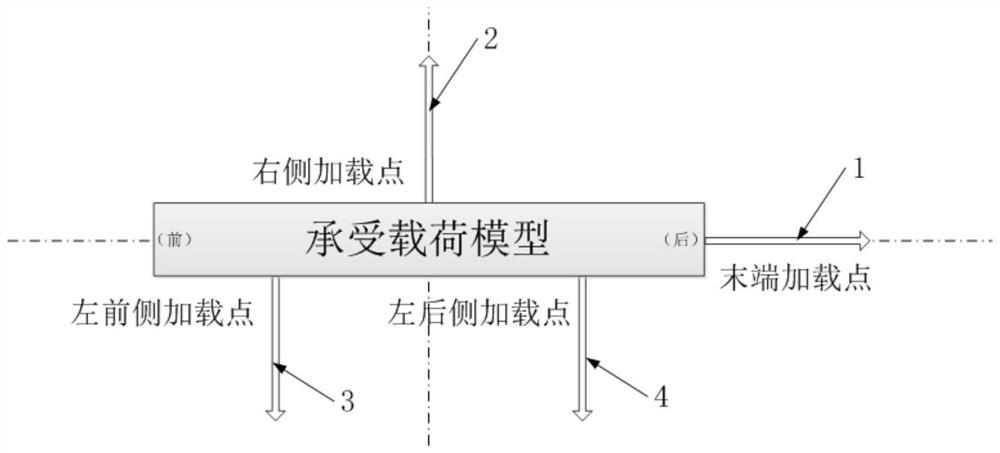

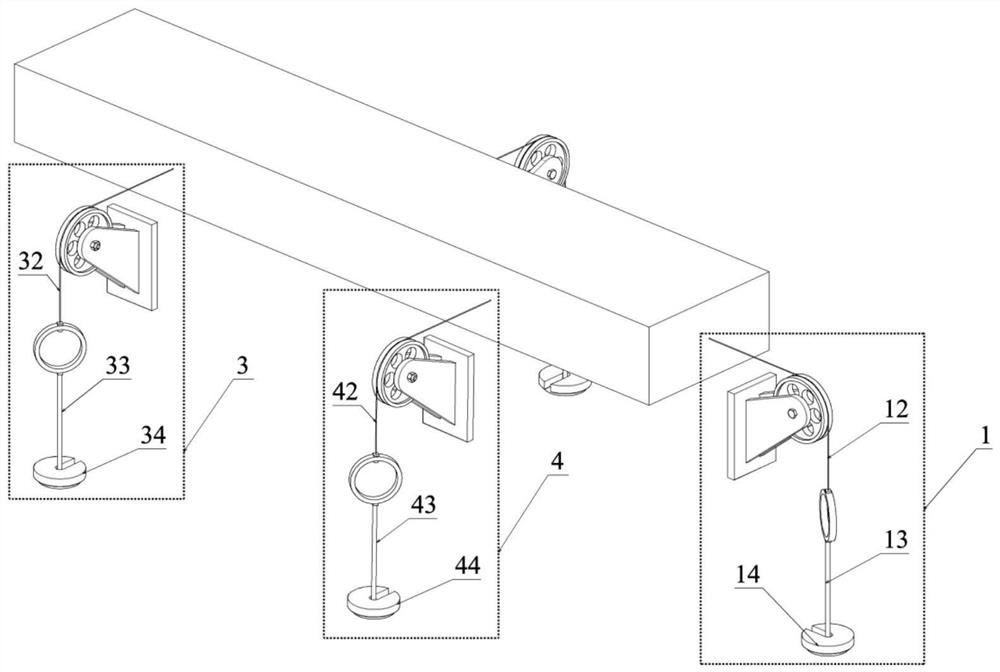

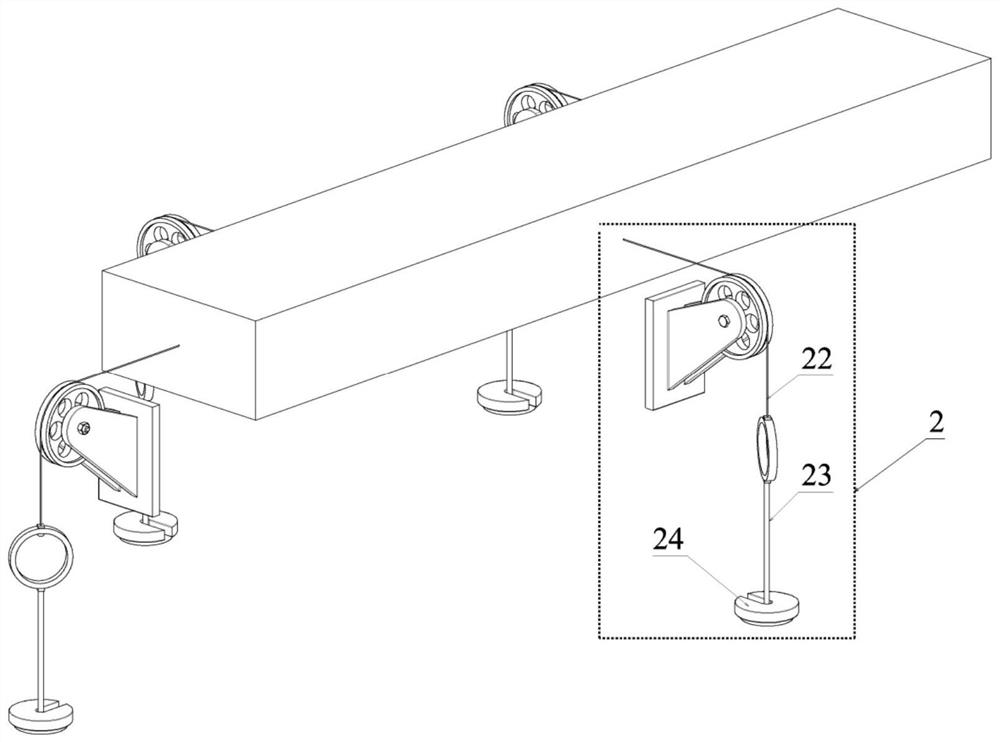

[0035] Before the test, the air buoyancy force measuring platform (also known as the air buoyancy platform / force measuring platform) can be calibrated in situ after the working position in the wind tunnel is adjusted and can work normally. The relationship between the output signal of the force measuring platform and the actual load is obtained by in-situ calibration. Select a suitable location on the force measuring platform to install the calibration piece, and connect the calibration piece to the model to provide a standard load for the load-bearing model in the force measuring platform. When calibrating, adjust the load size of the calibration parts in different positions, and design a suitable loading scheme. The load provided by the calibration piece to the model is a tensile load.

[0036] An in-situ calibration device for measuring a micro-aerodynamic air-floating platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com