Pulse axis control method based on CoDeSys controller

A control method and pulse axis technology, applied in the field of PLC technology, can solve problems such as inequitable treatment and inability to do closed-loop control, and achieve the effect of simplifying user operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

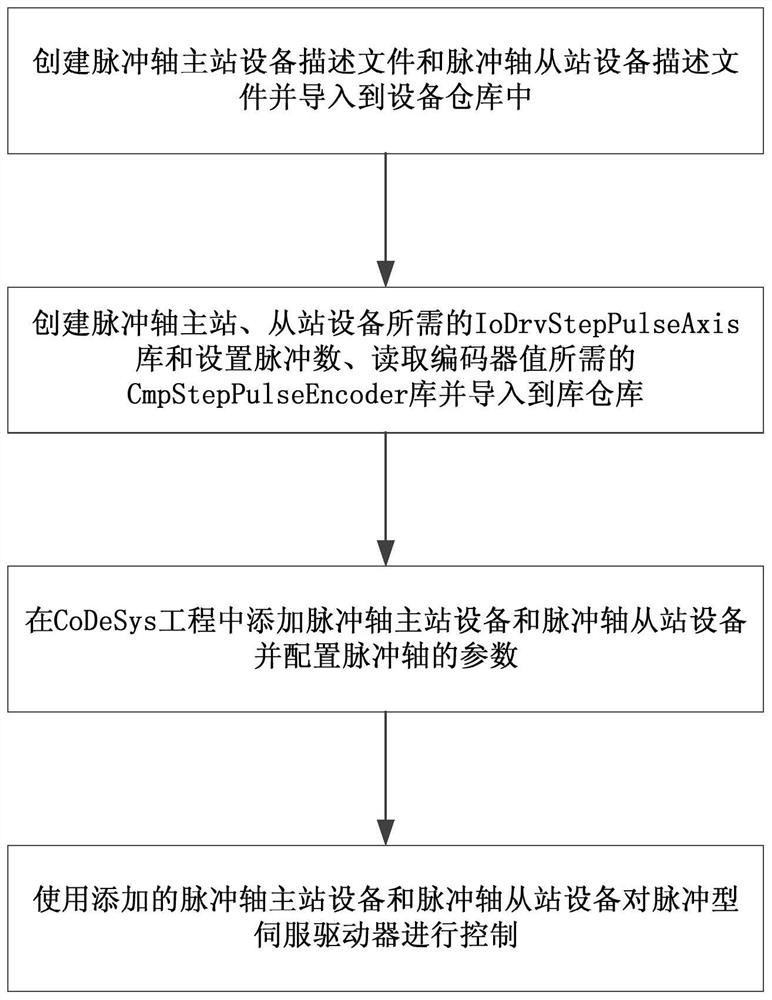

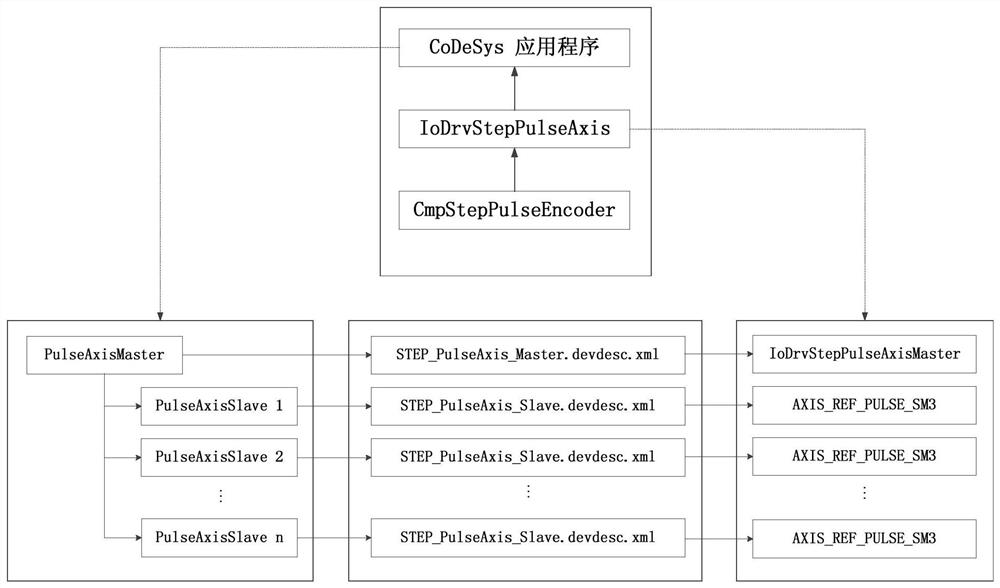

[0019] figure 1 It shows a schematic flow chart of a method for controlling a pulse axis based on a CoDeSys controller according to a specific embodiment of the present invention. The CoDeSys controller refers to a motion controller using the CoDeSys software of the German 3S company. Please refer to figure 1 , the pulse axis control method based on CoDeSys controller according to the embodiment of the present invention, comprises the following steps:

[0020] Create the device description file of the pulse axis master station and the device description file of the pulse axis slave station, and import the created device description file of the pulse axis master station and the device description file of the pulse axis slave station into the device warehouse of CoDeSys software;

[0021] Create the IoDrvStepPulseAxis library and the CmpStepPulseEncoder library, and import the IoDrvStepPulseAxis library and the CmpStepPulseEncoder library into the library warehouse of the CoDeS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com