Heat exchanger and corresponding production method

A technology of heat exchangers and manufacturing methods, applied in the direction of heat exchange equipment, heat exchanger tubes, heat exchanger types, etc., can solve problems such as inability to guarantee stability, installation obstacles, and limited performance indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

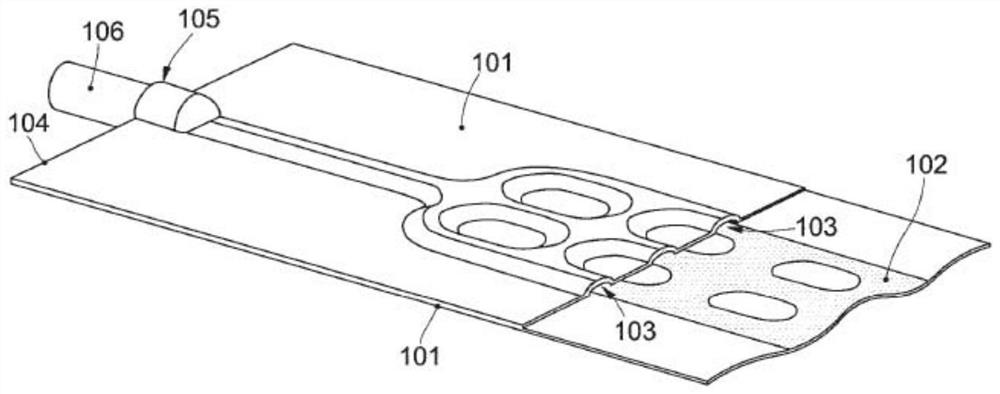

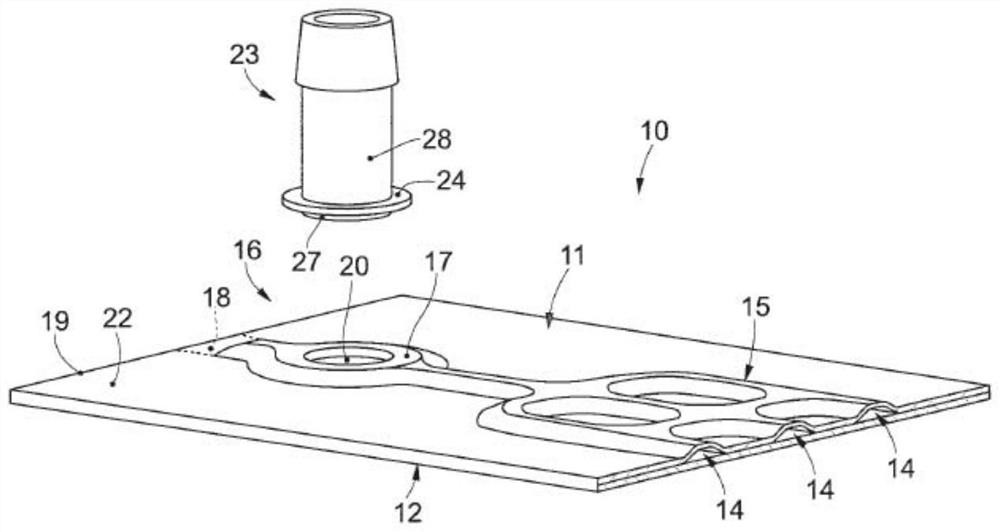

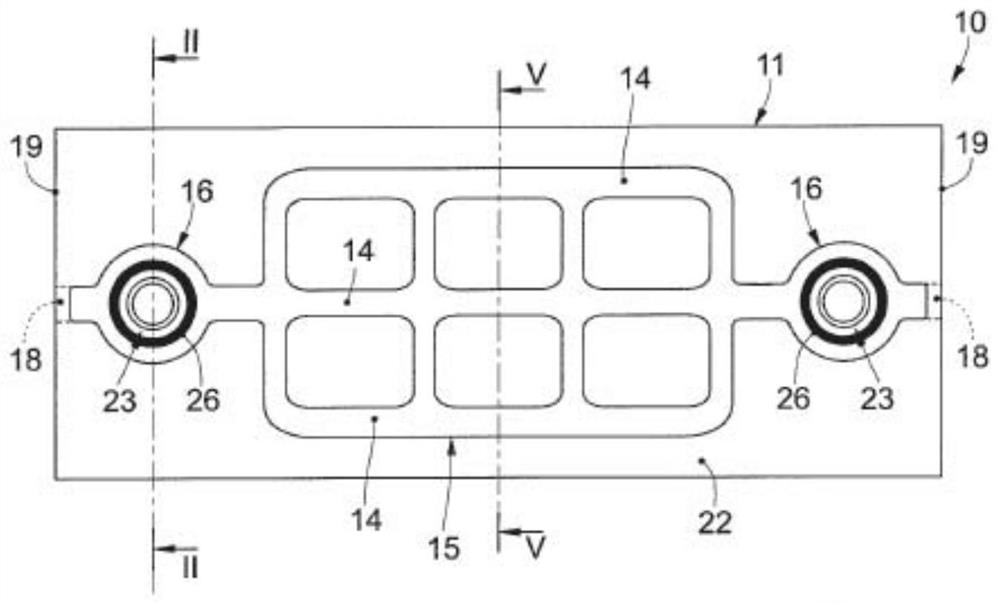

[0043]Refer to the attachmentfigure 2 AdherentFigure 6The present invention relates to a heat exchanger, which is integrally represented by reference numeral 10.

[0044]The heat exchanger 10 according to the present invention includes at least one first plate 11 and a second plate 12, the first plate 11 and the second plate 12 corresponding to each of the respective connecting surfaces 13 overlap each other and connected.

[0045]The plates 11, 12 have a substantially flat deployment having a substantially uniform thickness.

[0046]The boards 11, 12 may have the same thickness or may have different thicknesses.

[0047]The first plate 11 and the second plate 12 are made of a material having a low thermal resistance, such as an aluminum alloy. In particular, the choice of materials also depends on chemical compatibility and tolerance when contacting various heat-loaded fluids, or more, it is a function of corrosion resistance relative to the heat-loaded fluid.

[0048]As described below, by defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com