Control method of steam oven

A technology of a steam oven and a control method, which is applied in the direction of timing control of ignition mechanism, roaster/barbecue grid, household appliances, etc., can solve problems such as reducing the use experience, optimize the use experience, avoid excessive steam volume, reduce effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

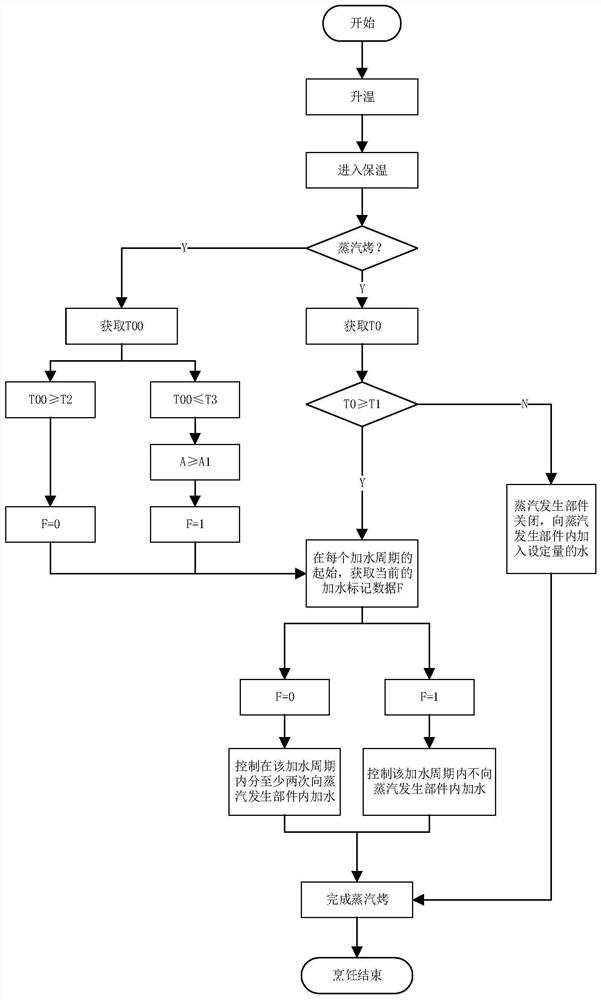

[0026] like figure 1 As shown, in the control method of the steam oven in this embodiment, for the cooking menu that requires humidified roasting, the steam roasting process is usually performed after the oven enters the heat preservation stage. The steam oven can be set according to the cooking process program. After entering the heat preservation stage, enter the steam roasting program according to the set time point. When the steam oven is working, if it enters the heat preservation stage, it will control the heating components such as the heating tube in the steam oven to work, and then control the temperature in the steam oven cavity to maintain the set heat preservation temperature. These heating components can be set as needed Upper heating element, back heating element and bottom heating element. The upper heating assembly may includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com