Adjustable air filter element cleaning device and cleaning method

A technology of air filter element and cleaning device, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of large filtering area, low operation efficiency, high labor intensity of staff, etc., to achieve convenient use and reduce capital occupation. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

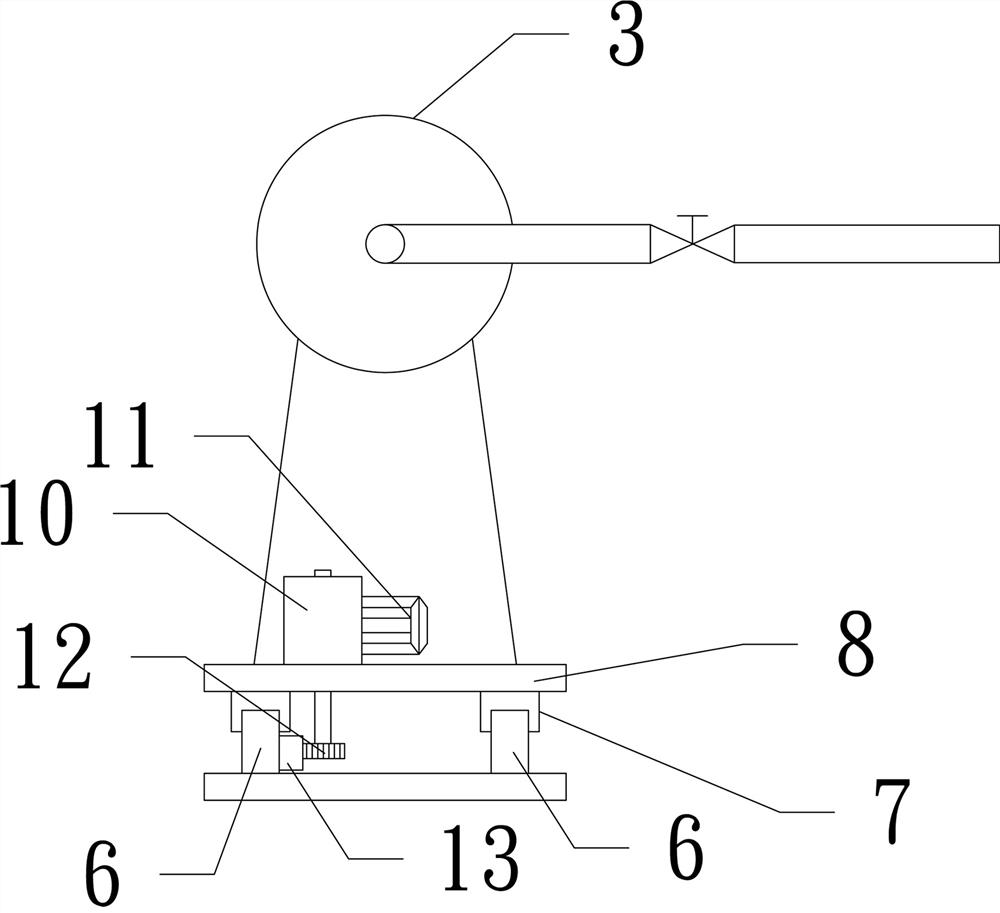

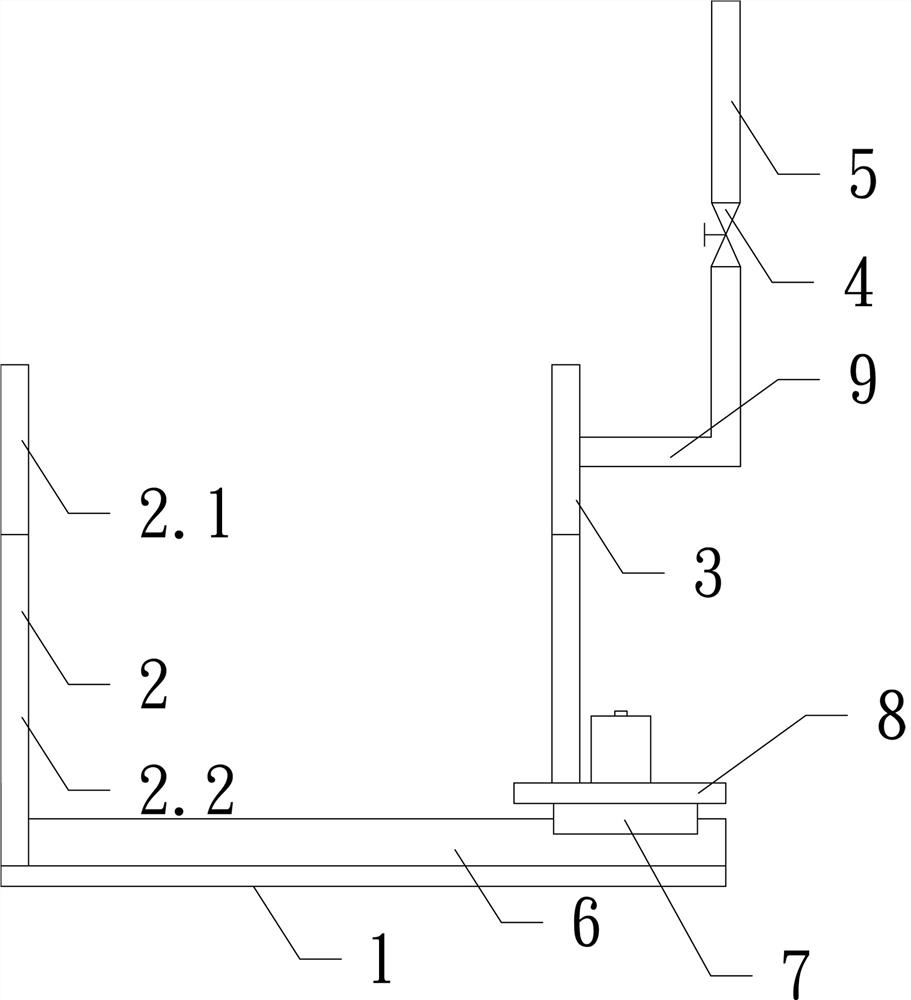

[0028] Such as Figure 1-2 As shown, the adjustable air filter element cleaning device.

[0029] It includes a base 1, a fixed plate 2 and a movable fixed plate 3 parallel to each other, a fixed plate 2 is installed at one end of the base 1, a guide rail 6 is installed on the upper surface of the base 1 along its length, and the guide rail 6 is slidably installed Slide block 7 is arranged, and described slide block 7 is fixed on the bottom of movable fixed disk mount 8, and movable fixed disk 3 is installed on described movable fixed disk mount 8, and the fixed disk 2 or movable fixed disk 3 There is an air guide pipe 9 in the center, the other end of the air guide pipe 9 is connected to the shut-off valve 4 , and the other end of the shut-off valve 4 is connected to the high-pressure air pipe 5 .

[0030] In this embodiment, two guide rails 6 are installed; the fixed plate 2 and the movable fixed plate 3 have the same structure; the fixed plate 2 includes an upper disc 2.1 a...

Embodiment 2

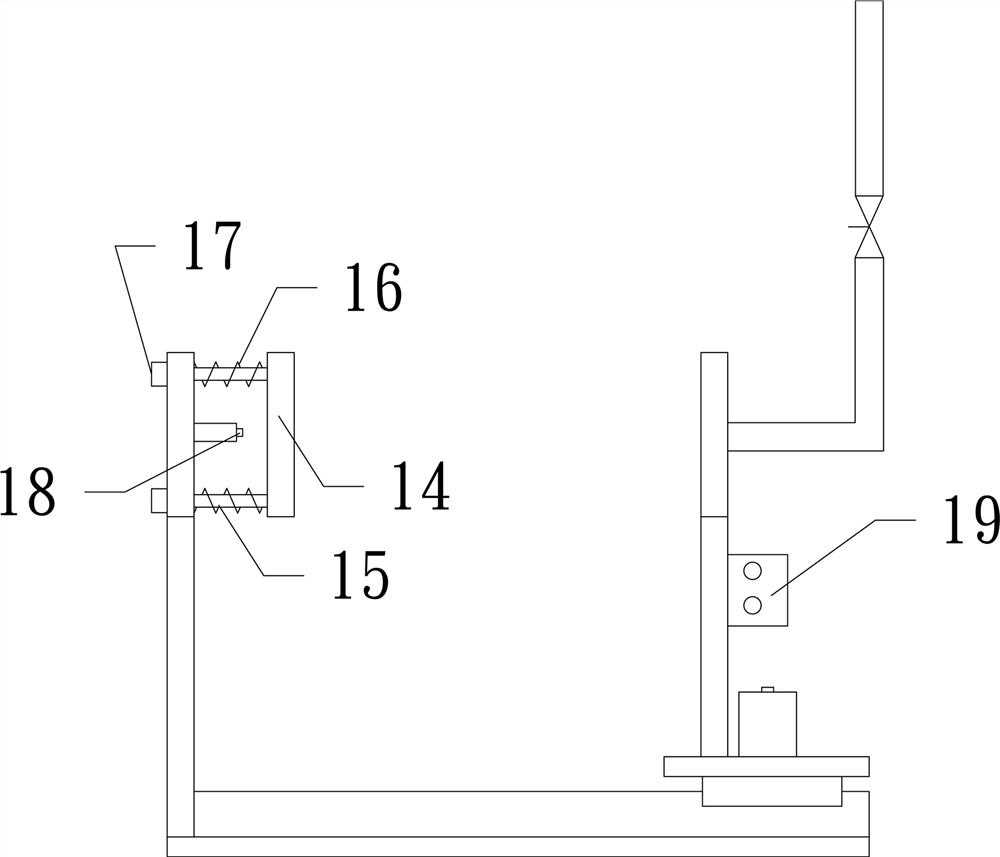

[0032] Embodiment two, refer to image 3 , the difference from Embodiment 1 is that a damping mechanism is provided on the inner side of the upper disk 2.1; , the clamping disc 14 is located on the inner side of the upper disc 2.1, and is parallel to the upper disc 2.1, the outer surface of the clamping disc 14 is vertically connected with a plurality of guide posts 15, and the other guide posts 15 One end runs through the upper disc 2.1, and an end baffle 17 is installed at the end, and a buffer spring 16 is sleeved on the guide column 15 between the upper disc 2.1 and the clamping disc 14, and the buffer spring 16 The two ends of the upper disc 2.1 and the clamping disc 14 are respectively abutted against; the inner side of the upper disc 2.1 has a pressure sensor 18, and the pressure sensor 18 is installed on the upper disc 2.1 through a pressure sensor support, and the pressure The sensor support is installed at the center of the upper disc 2.1, the buffer spring 16 is a ...

Embodiment 3

[0033] Embodiment 3, the present invention also discloses a method for cleaning an adjustable air filter element.

[0034]It is applicable to the columnar air filter element. The two ends of the air filter element are respectively abutted on the clamping disc 14 and the upper disc of the movable fixed disc. The air filter element is set concentrically with the clamping disc 14 as far as possible, press the forward rotation button on the controller 19, the travel motor 10 drives the travel reducer 11 to work, the travel reducer 11 drives the drive gear 12 to rotate, and the drive gear 12 and the rack 13 With cooperation, the movable fixed disk 3 approaches the fixed disk 2 until the two ends of the air filter element abut against the upper disk of the fixed disk and the movable fixed disk respectively, as the buffer spring 16 on the guide column 15 is compressed , the pressure sensor 18 on the upper disk 2.1 is in contact with the clamping disk 14. When the set pressure value i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com