A method for screening solid particle fertilizers with unqualified particle size based on screening equipment

A technology of solid particles and screening equipment, which is applied in the agricultural field, can solve the problems that cannot be automatically removed and screened, and achieve the effects of intelligent screening process, increased yield, and high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

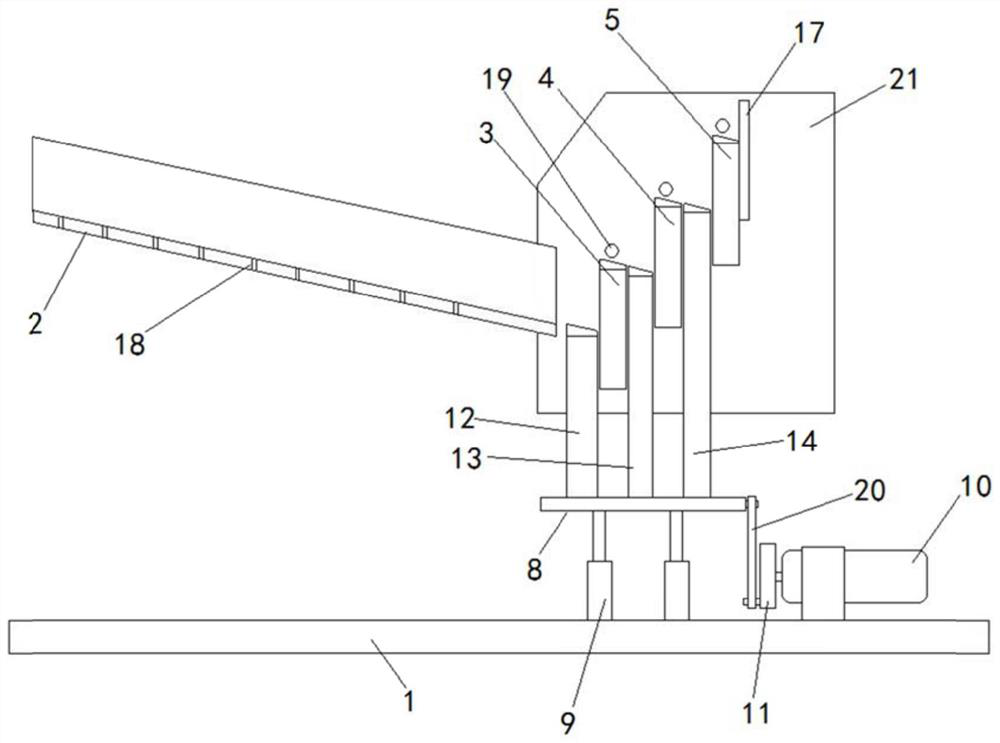

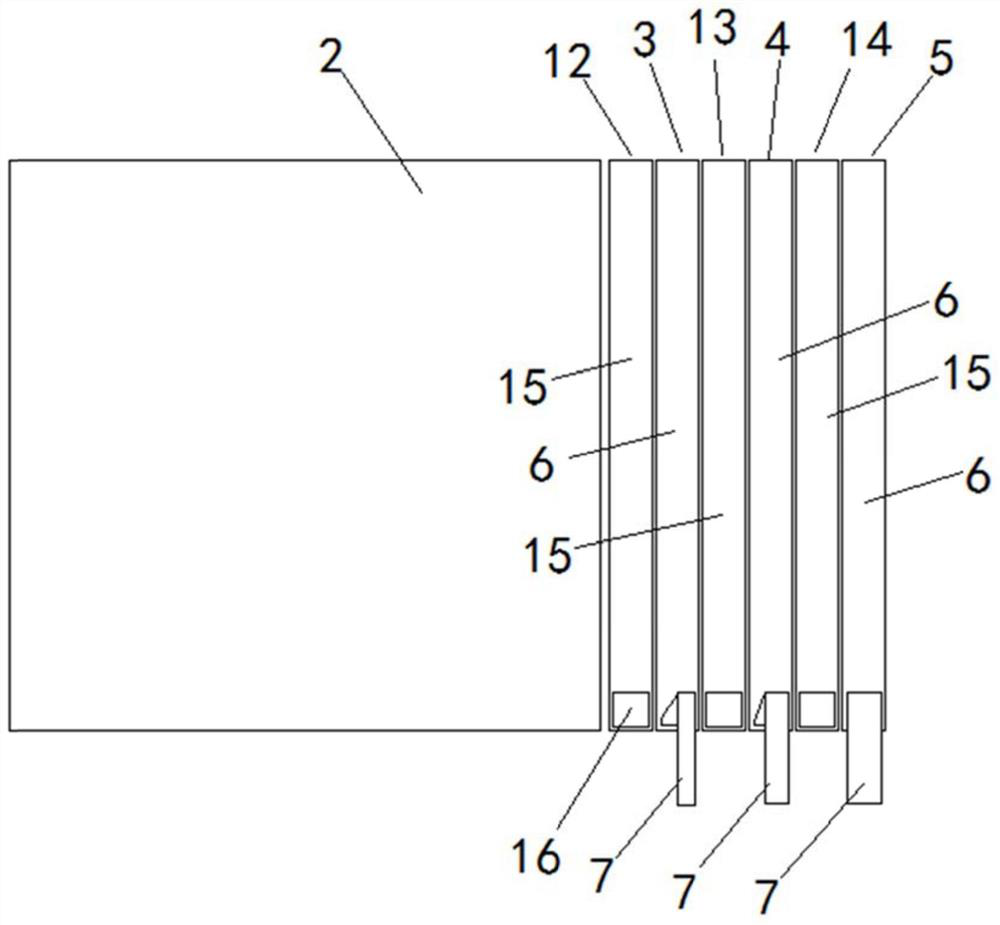

[0023] The preferred technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

[0024] A screening method for unqualified particle size solid particle fertilizer based on screening equipment of the present invention, based on a screening device, includes a bottom plate 1, the bottom plate 1 is fixedly provided with a sloping plate 2, and the inclined plate 2 is located above the bottom plate 1 and maintains a certain inclination, It is convenient for the solid granular fertilizer to roll from top to bottom. Note that it is best not to accumulate the solid granular fertilizer on the inclined plate 2, and try to keep one layer as much as possible.

[0025] A first vertical plate 3 , a second vertical plate 4 and a third vertical plate 5 are arranged on the outer side of the lower end in the inclined direction of the inclined plate 2 in sequence, and the first vertical plate 3 , the second vertical plate 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com