Repositioning method for numerical control thread milling

A CNC milling and repositioning technology, which is applied to wire cutters, metal processing equipment, manufacturing tools, etc., can solve the problems of inaccurate tool setting, spending a lot of time, and scrapped workpieces, saving tool setting time and improving tool setting efficiency. , to avoid the effect of thread disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

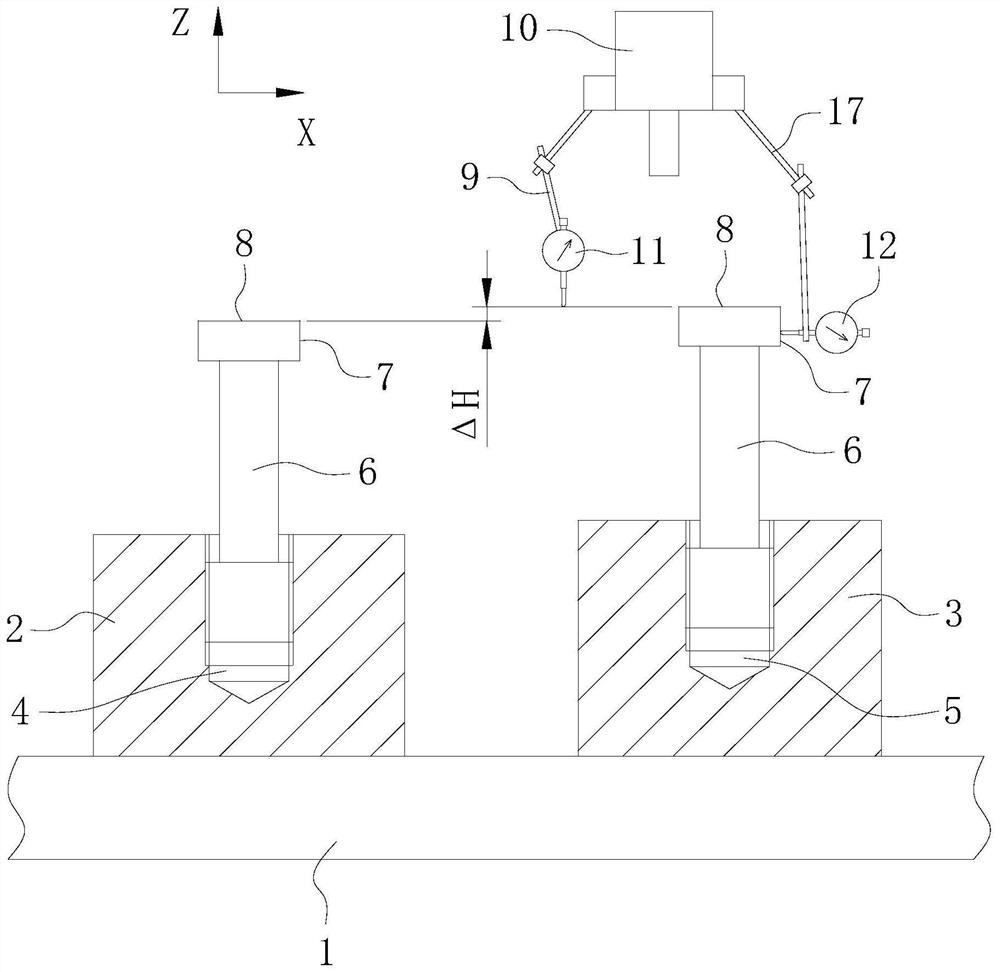

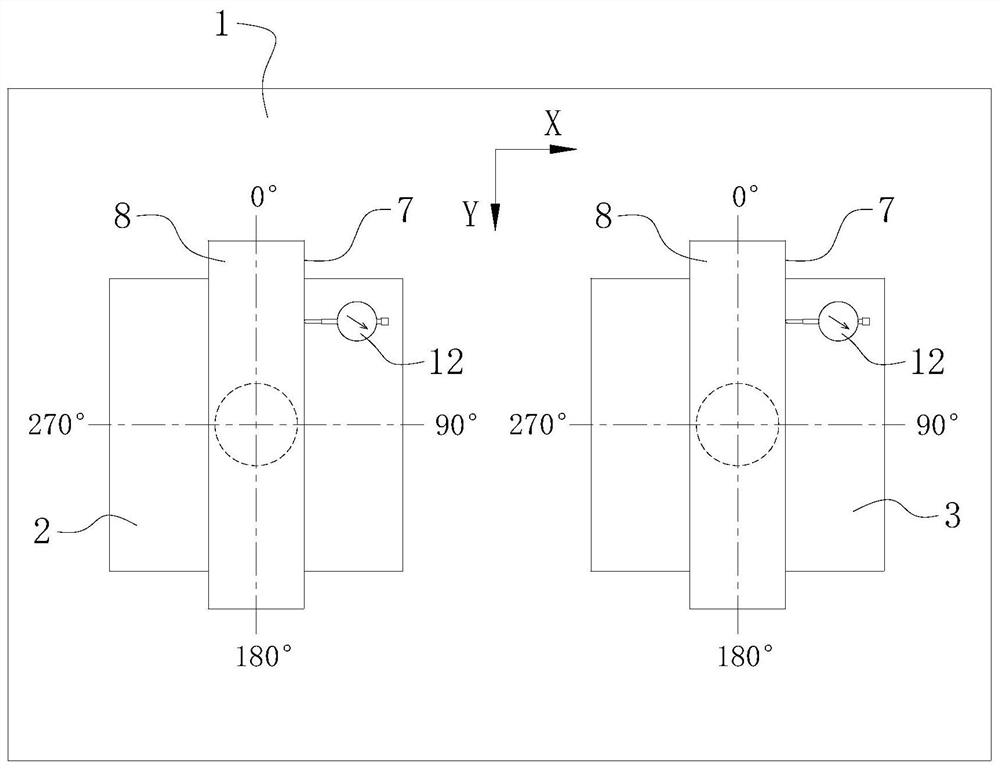

[0085] S1, see figure 1 , install the test piece 3 on the G54 coordinate system plane of the workbench 1, and determine the zero point coordinate x of the test threaded hole 5 in the X direction with the center line of the test threaded hole 5 to be processed in the test piece 3 0 ’ and the zero point coordinate y in the Y direction 0 ’; the tip of the thread milling cutter coincides with the end face of the test threaded hole 5 to be processed to determine the zero point coordinate z of the test threaded hole 5 in the Z direction 0 '.

[0086] Install the reworked part 2 on the G55 coordinate system plane of the workbench 1, and determine the zero coordinate x of the reworked threaded hole 4 in the X direction with the center line of the reworked threaded hole 4 0 and the zero point coordinate y in the Y direction 0 ;At this time, the zero point coordinate z of threaded hole 4 in the Z direction is repaired 0 Not sure yet.

[0087] S2. Mill out the test threaded hole 5 o...

Embodiment 2

[0123] S1, see Figure 5 , install the test piece 3 on the G54 coordinate system plane of the workbench 1, and determine the zero point coordinate x of the test threaded hole 5 in the X direction with the center line of the test threaded hole 5 to be processed in the test piece 3 0 ’ and the zero point coordinate y in the Y direction 0’; the tip of the thread milling cutter coincides with the end face of the test threaded hole 5 to be processed to determine the zero point coordinate z of the test threaded hole 5 in the Z direction 0 '.

[0124] Install the reworked part 2 on the G55 coordinate system plane of the workbench 1, and determine the zero coordinate x of the reworked threaded hole 4 in the X direction with the center line of the reworked threaded hole 4 0 and the zero point coordinate y in the Y direction 0 ;At this time, the zero point coordinate z of threaded hole 4 in the Z direction is repaired 0 Not sure yet.

[0125] S2. Mill out the test threaded hole 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com