Industrially constructed underground station structure and construction method

A technology for underground stations and stations, which is applied to underwater structures, infrastructure engineering, buildings, etc., and can solve the problems of many types of prefabricated components, poor overall stability, and complex contours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

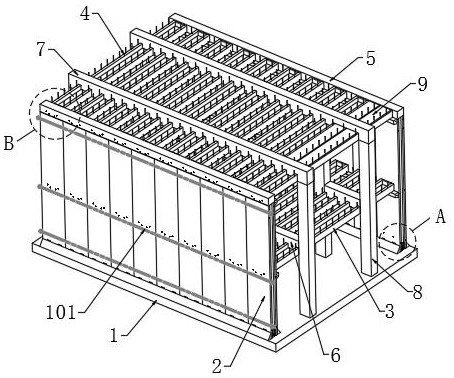

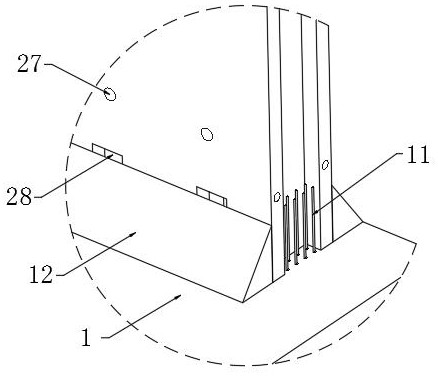

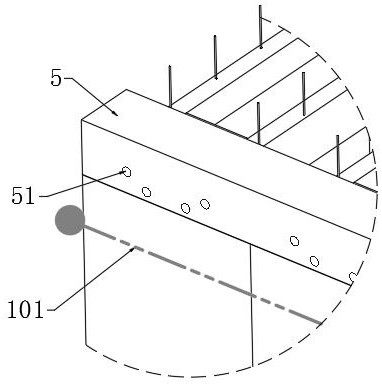

[0045] see figure 1 with Image 6 , the present invention provides an industrial construction underground station structure, comprising a cast-in-place floor 1, a prefabricated side wall 2, a first U-shaped beam 3, a second U-shaped beam 4, a crown beam 5, a first longitudinal beam 6, a second longitudinal Anti-beam 7 , prefabricated column 8 , longitudinal anchor cable 101 , first transverse anchor cable 102 and second transverse anchor cable 103 . in. The prefabricated side wall 2, the first U-shaped beam 3, the second U-shaped beam 4 and the prefabricated column 8 are all prefabricated components, and the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com