Steel bar truss floor support plate with clamping grooves

A technology of reinforced trusses and clamping grooves, which is applied in the field of reinforced truss floor decks, which can solve the problems of time-consuming and labor-intensive keel installation and high hardness of cement boards, and achieve the effects of reducing construction difficulty, facilitating leveling, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

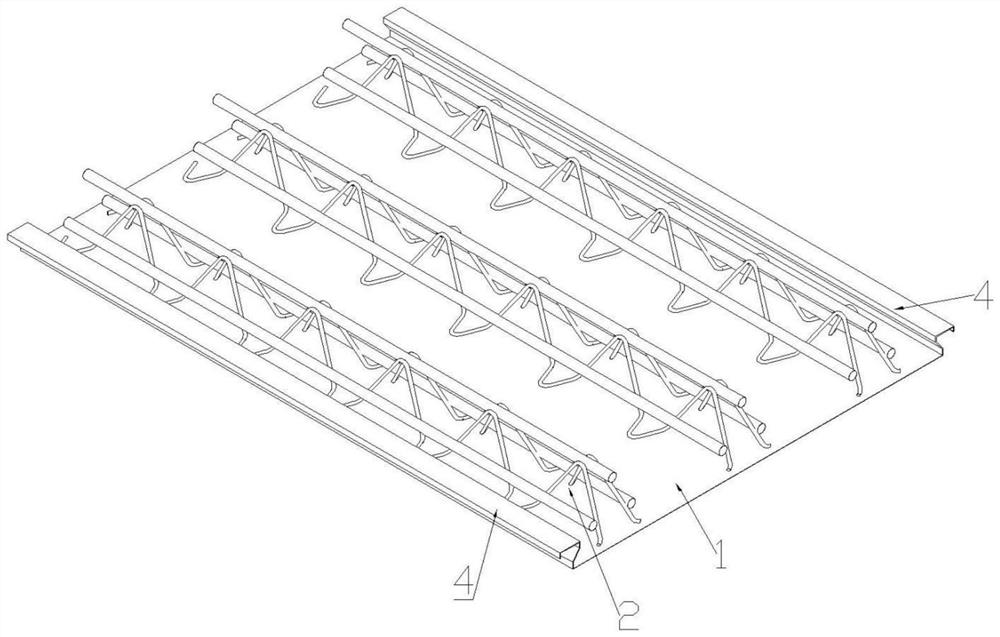

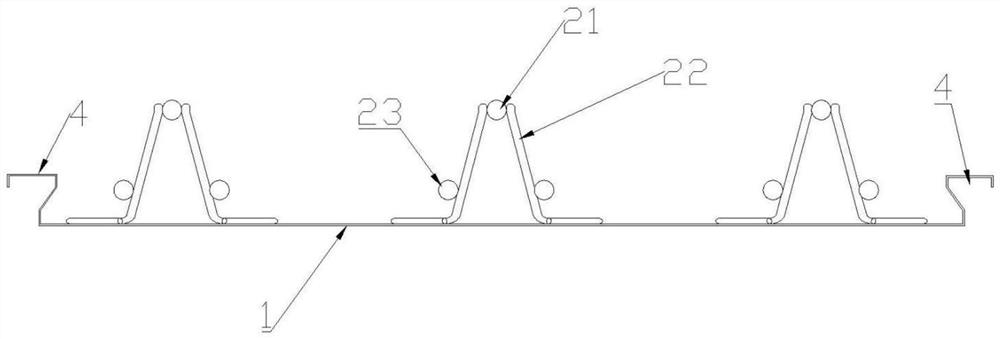

[0026] Such as figure 1 and figure 2 As shown, the present invention proposes a steel bar truss 2 floor bearing plate with a clamping groove 4, including a bottom plate 1, a steel bar truss 2 and a ceiling connector 3, the steel bar truss 2 is fixed on the bottom plate 1, and the back of the bottom plate 1, that is, the back A clamping groove 4 is provided on one side of the steel truss 2, and the clamping groove 4 is arched toward the side connecting the steel truss 2; the ceiling connector 3 is clamped in the clamping groove 4, and the ceiling connector 3 and the ceiling 5 Make the connection.

[0027] The clamping groove 4 cooperates with the design of the ceiling connector 3, which is convenient to use self-tapping screws to connect the gypsum board or other decorative boards to the bottom of the floor deck to form a suspended ceiling, which reduces the difficulty of construction and protects the overall structure of the floor deck. Self-tapping nails are not only labor...

Embodiment 2

[0035] Embodiment 2 has the same overall structure as Embodiment 1, except that the ceiling connector 3 is a spring connecting piece 34 , the structure of the locking groove 4 and the position relative to the bottom plate 1 are different.

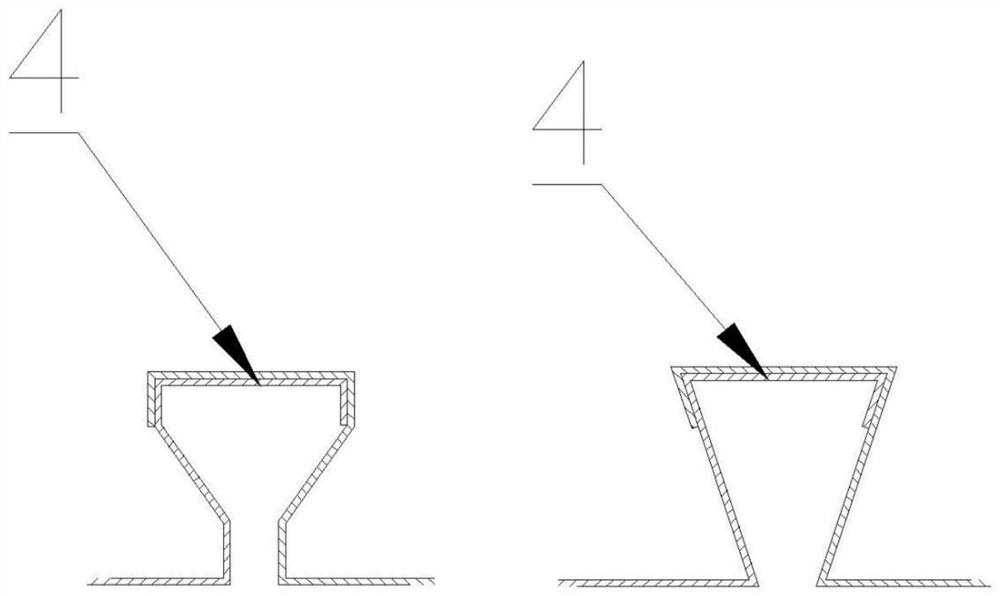

[0036] Such as Image 6 As shown, the clamping groove 4 includes any one of the dovetail groove 41, the T-shaped groove 42 or the double inclined groove 43, but is not limited to one of them, and the slot hole with the clamping effect can be used as the embodiment of the present invention As an example, the position of the clamping groove 4 is based on actual engineering requirements. If it is necessary to realize the overlap between the floor decks, it can be placed on both sides of the bottom plate 1. If not, it can also be placed as Image 6 As shown, it is placed near the middle of the bottom plate 1.

[0037] In this embodiment, the ceiling connector 3 is a spring connecting piece 34, and the spring connecting piece 34 includes two el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com